Impermeable frost-resistant concrete and preparation method thereof

A technology for concrete and frost resistance, applied in the field of concrete, can solve the problems of long preparation process time, poor effect of concrete frost resistance and impermeability, low concrete mixing and coagulation efficiency, etc. Antifreeze and coagulation effect, improvement of impermeability and antifreeze durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

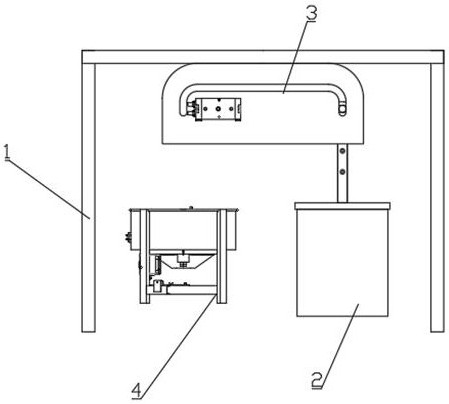

[0037] see Figure 1-6 As shown, a kind of impermeable and frost-resistant concrete is characterized in that: it is composed of the following raw materials in parts by weight: 820 parts of machine-made sand, 950 parts of gravel, 7 parts of water reducing agent, 115 parts of water, 50 parts of air-entraining agent, antifreeze 50 parts of agent; wherein, the air-entraining agent is the mixture of saponin and dodecyl dimethylamine oxide, and the weight ratio of saponin and dodecyl dimethylamine oxide is 100:2; antifreeze The agent is a mixture of sodium nitrite and urea, and the weight ratio of sodium nitrite and urea is 8:8;

[0038] The preparation method of the anti-seepage and frost-resistant concrete comprises the following steps:

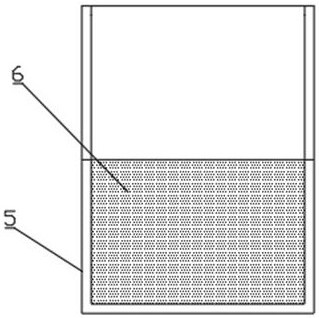

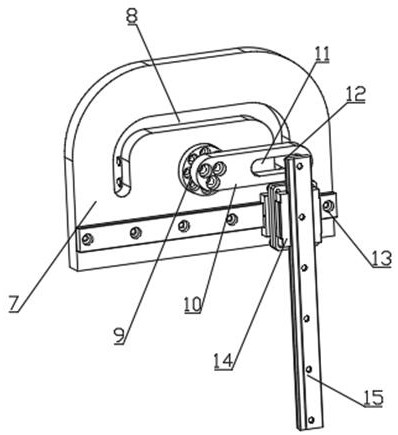

[0039] Step 1: Cut saponins into granules, add them into the cleaning frame, and then control the rotating motor to work through the transfer device 3 on the bracket 1, and drive the rotating shaft 9 to rotate, so that the rotating plate 10 driv...

Embodiment 2

[0049] Compared with Example 1, the difference lies in: an impermeable and frost-resistant concrete, characterized in that it is composed of the following raw materials in parts by weight: 840 parts of machine-made sand, 980 parts of gravel, 9 parts of water reducing agent, and 120 parts of water , 55 parts of air-entraining agent, 55 parts of antifreeze; Wherein, the air-entraining agent is the mixture of saponin and dodecyldimethylamine oxide, the mixture of saponin and dodecyldimethylamine oxide The weight ratio is 105:3; the antifreeze is a mixture of sodium nitrite and urea, and the weight ratio of sodium nitrite and urea is 9:9;

Embodiment 3

[0051] Compared with Example 1, the difference is: an impermeable and frost-resistant concrete, characterized in that it is composed of the following raw materials in parts by weight: 860 parts of machine-made sand, 1000 parts of gravel, 11 parts of water reducing agent, and 125 parts of water , 60 parts of air-entraining agent, 60 parts of antifreeze; Wherein, the air-entraining agent is the mixture of saponin and dodecyldimethylamine oxide, the mixture of saponin and dodecyldimethylamine oxide The weight ratio is 110:4; the antifreeze is a mixture of sodium nitrite and urea, and the weight ratio of sodium nitrite and urea is 10:10;

[0052] Working principle of the present invention: an anti-seepage and frost-resistant concrete, characterized in that it is composed of the following raw materials in parts by weight: 820-860 parts of machine-made sand, 950-1000 parts of crushed stone, 7-11 parts of water reducing agent, and 115 parts of water -125 parts, 50-60 parts of air-ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com