Drought-resisting and boll-protecting water-soluble fertilizer and preparation method thereof

A water-soluble fertilizer and pretreatment technology, applied in the direction of nitrogen fertilizer, potassium fertilizer, magnesium fertilizer, etc., can solve the problem of high shedding rate of buds and bolls, achieve thick stems, prevent cotton bolls from falling off, and prevent adhesion and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

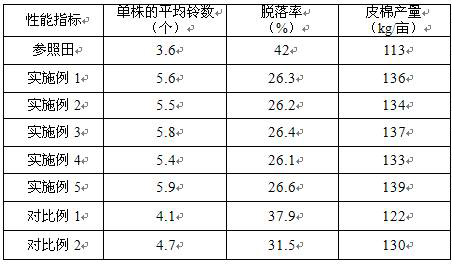

Examples

Embodiment 1

[0036] (1) Dry the chaff, then mix 35kg of dried chaff with 4kg of polyvinyl alcohol and finely grind it through a jet mill, then transfer the grinding material to a ball mill, add 18kg of potassium sulfate and 12kg of dihydrogen phosphate Potassium ball milling, the speed of the ball milling is controlled at 400rpm, the ball milling is 30min, and the material is discharged to obtain the pretreated material;

[0037] (2) Mix 1.5kg sodium 2,4-dinitrophenolate, 5kg sodium p-phenylnitrophenolate, 2kg sodium o-phenylnitrophenolate, and 10kg naphthaleneacetic acid to obtain a compound rooting agent;

[0038] (3) Grind and compound 100kg pregelatinized corn starch, 4kg guar gum, 1.5kgEDTA-Zn, 0.8kgEDTA-Mn, 0.15kgEEDTA-Fe, 2.5kg boric acid, 0.06kg potassium indolebutyrate, and pass through 100 mesh Sieve, then add in the high-speed mixer, spray 20kg of water while stirring at high speed, control the rotating speed of high-speed stirring at 550rpm, stir for 35min, make part of pregela...

Embodiment 2

[0042] (1) Dry the chaff of bacteria, then mix 38kg of dried chaff with 3.5kg of polyvinyl alcohol and finely grind it through a jet mill, then transfer the grinding material to a ball mill, add 16kg of potassium sulfate, 11kg of diphosphate Hydrogen potassium ball milling, the speed of the ball milling is controlled at 350rpm, the ball milling is 32min, and the material is discharged to obtain the pretreated material;

[0043] (2) Mix 1.2kg of sodium 2,4-dinitrophenolate, 4.5kg of sodium p-phenylnitrophenolate, 1.5kg of sodium o-phenylnitrophenolate, and 11kg of naphthaleneacetic acid to obtain a compound rooting agent;

[0044] (3) Grind 100kg pregelatinized water chestnut starch, 3.5kg guar gum, 1.2kgEDTA-Zn, 0.6kgEDTA-Mn, 0.12kgEEDTA-Fe, 2.2kg boric acid, 0.03kg potassium indolebutyrate, and then pass 100 Mesh sieve, then add in the high-speed mixer, spray 15kg of water while stirring at high speed, control the rotating speed of high-speed stirring at 520rpm, stir for 38mi...

Embodiment 3

[0048] (1) Dry the chaff, then mix 32kg of the dried chaff with 4.5kg of polyvinyl alcohol and finely grind it in a jet mill, then transfer the grinding material to a ball mill, add 18kg of potassium sulfate, 14kg of diphosphate Hydrogen potassium ball milling, the speed of the ball milling is controlled at 450rpm, the ball milling is 28min, and the material is discharged to obtain the pretreated material;

[0049] (2) Mix 1.8kg of sodium 2,4-dinitrophenolate, 5.5kg of sodium p-phenylnitrophenolate, 2.5kg of sodium o-phenylnitrophenolate, and 9kg of naphthaleneacetic acid to obtain a compound rooting agent;

[0050] (3) Grind and compound 100kg pregelatinized potato starch, 4.5kg guar gum, 1.8kgEDTA-Zn, 0.8kgEDTA-Mn, 0.18kgEEDTA-Fe, 2.8kg boric acid, 0.08kg potassium indolebutyrate, and then pass 100 Mesh sieve, then add in the high-speed mixer, spray 25kg of water while stirring at high speed, control the rotating speed of high-speed stirring at 580rpm, stir for 32min, make p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com