Method for separating and extracting lycopene from fermentation liquor

A technology of lycopene and fermented liquid, applied in the direction of extraction and purification/separation, crystallization purification/separation, chemical instruments and methods, etc., can solve the problems of long chemical synthesis process route, food safety impact, toxic substance residue, etc., to achieve The effect of important application value, low cost and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, the establishment of the method for separating and extracting lycopene from fermented liquid

[0038] 1. Experimental exploration of separation and extraction of lycopene from fermentation broth

[0039] The experiment was repeated three times to take the average value, and the steps for each repetition were as follows:

[0040]1. Take the recombinant Escherichia coli LYC029 fermentation broth, centrifuge, and collect the bacterial cells.

[0041] 2. Take a 500mL Erlenmeyer flask, add 100g of bacteria and 400mL of ethyl acetate, mix well, soak for 1 day, and collect the supernatant. Take 1 mL supernatant with a pipette, dilute 100 times with acetone, and then detect OD 474nm and OD 506nm .

[0042] 3. After completing step 2, add 400mL ethyl acetate to the Erlenmeyer flask, mix well, continue soaking for 1 day, and collect the supernatant. Take 1 mL supernatant with a pipette, dilute 100 times with acetone, and then detect OD 474nm and OD 506nm .

...

Embodiment 2

[0066] Example 2, Experiment 1 of Separating and Extracting Lycopene from Recombinant Escherichia coli LYC029 Fermentation Broth

[0067] 1. Take 10L of recombinant E. coli LYC029 fermentation broth (the concentration of lycopene in the recombinant E. coli LYC029 fermentation broth is 4g / L), centrifuge in a tubular centrifuge, and collect 3.3kg of thalline.

[0068] 2. After completing step 1, take 40g of bacteria, add 40mL of ethanol to soak for 1 hour, filter, filter with a sand core funnel, and collect the precipitate (about 10g).

[0069] 3. After completing step 2, wash the precipitate twice with ethanol, and collect the bacteria powder (about 10g).

[0070] The method of each washing is as follows: slowly add 10 mL of ethanol to the precipitate for rinsing, stir evenly and filter with suction.

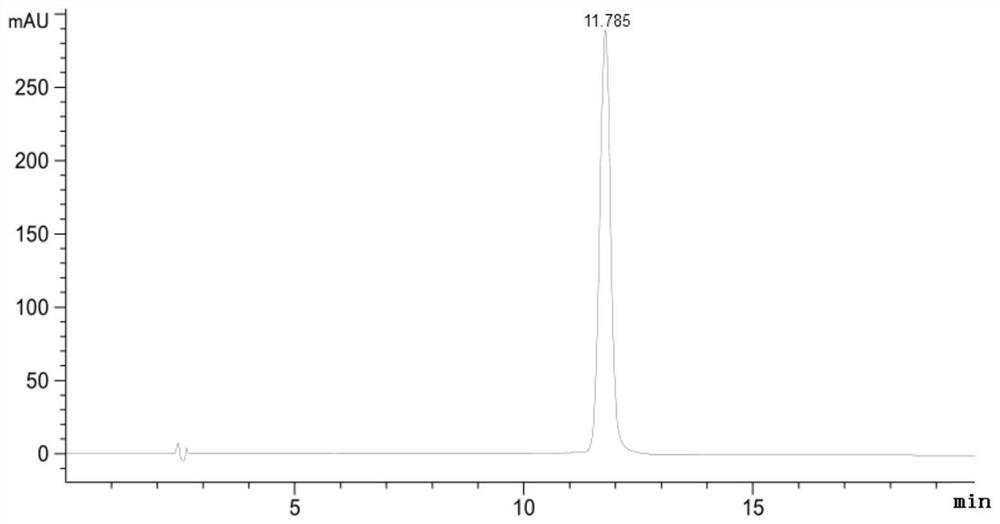

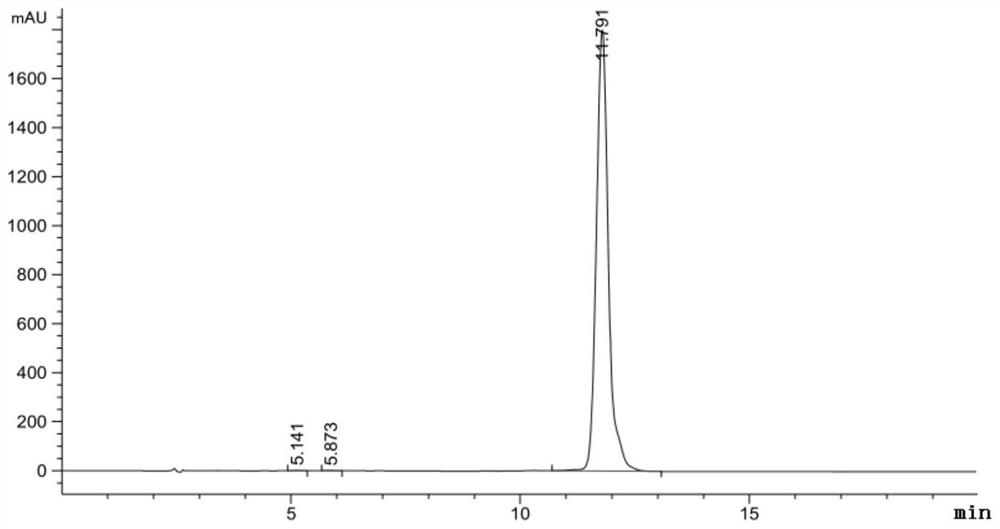

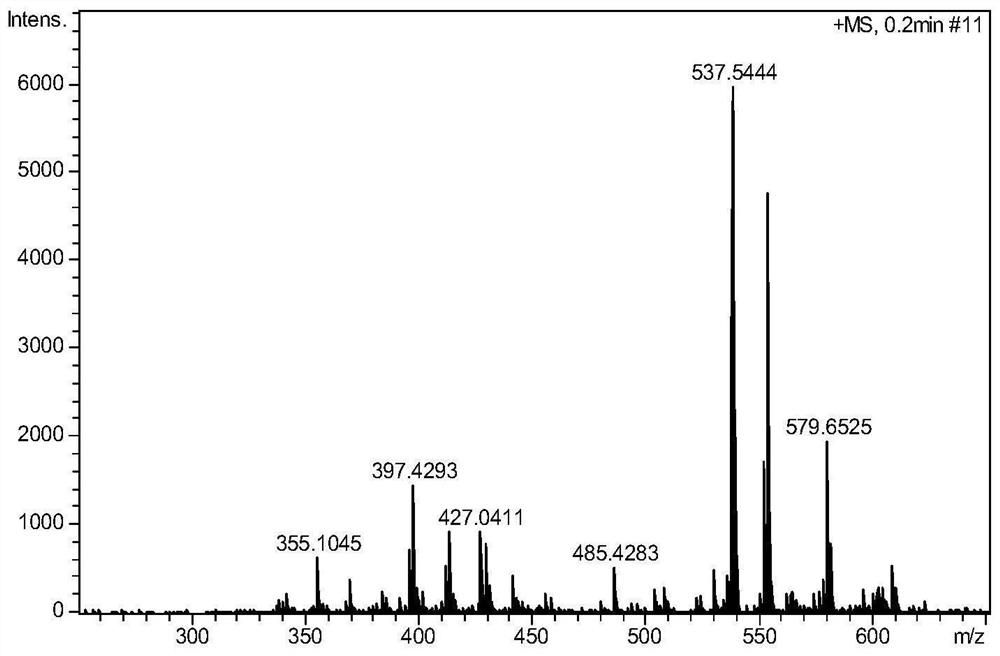

[0071] 4. After completing step 3, transfer the bacterial powder to a 1L three-necked flask, add 200mL of ethyl acetate, extract 3 times at 60°C, combine the ethyl acetate phase...

Embodiment 3

[0079] Example 3, Experiment 2 of Separating and Extracting Lycopene from Recombinant Escherichia coli LYC029 Fermentation Broth

[0080] 1. Take 30L of recombinant E. coli LYC029 fermentation broth (the concentration of lycopene in the recombinant E. coli LYC029 fermentation broth is 4g / L), centrifuge in a tubular centrifuge, and collect 9.9kg of thallus.

[0081] 2. After completing step 1, take 320g of bacteria, add 320mL of ethanol to soak for 2 hours, filter, and filter with a sand core funnel to collect the precipitate (about 80g).

[0082] 3. After completing step 2, wash the precipitate twice with ethanol, and collect the bacteria powder (about 80g).

[0083] The method of each washing is: slowly add 80mL of ethanol to the precipitate for rinsing, stir evenly and filter with suction.

[0084] 4. After completing step 3, transfer the bacterial powder to a three-necked flask, add 1.6L ethyl acetate, extract twice at 60°C, combine the ethyl acetate phase to obtain an org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com