Boiler flue equal-service-life high-temperature anti-corrosion coating composite material and application thereof

A high-temperature anti-corrosion, coating material technology, applied in the direction of coating, metal material coating process, melt spraying, etc., can solve the problems of natural resources and energy waste, large difference in service life, heavy economic burden, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

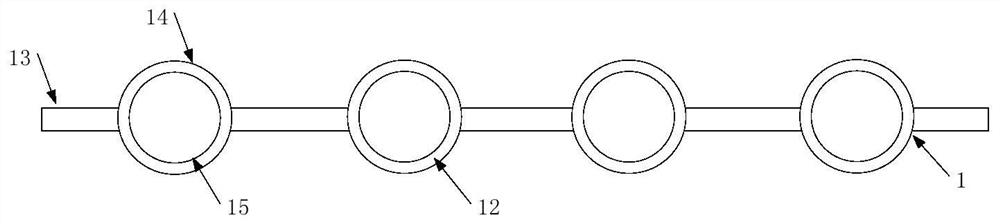

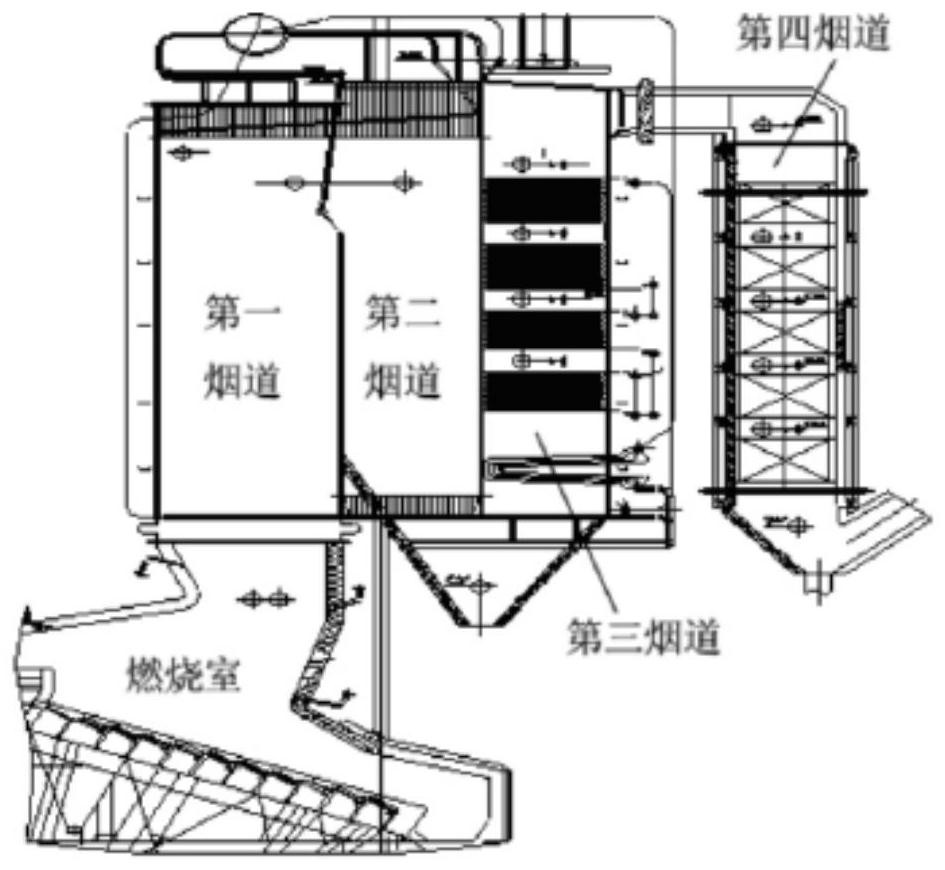

[0217] (1) Taking the actual boiler as the research object, statistically analyze the failure law data of the "four-tube" coating of this type of boiler along the flue and the spatial position, including the corrosion thinning law, burst tube, etc., and determine each flue according to these data. The surface corrosion of the heating surface of the pipeline is divided into four areas and parts and their distribution rules: ultra-high temperature chemical corrosion, medium / high temperature chemical corrosion, electrochemical corrosion / strong corrosion, electrochemical corrosion / weak corrosion.

[0218] (2) According to the actual working conditions of the boiler, design a "one piece, one material" anti-corrosion scheme.

[0219] The general principle is to choose high-performance coating protection methods and coating materials for the areas and parts of the pipe wall with high wall temperature and high corrosion rate under the principle of equal service life of each flue pipe, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com