Titanium substrate with in-situ growth of metal nanoparticles on the surface and its application

A technology of in-situ growth of metal nanoparticles, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of uneven distribution of metal nanoparticles, inability to use in large quantities, and easy shedding of nanoparticles and other problems, to achieve the effect of mass production, simple and rapid preparation operation, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

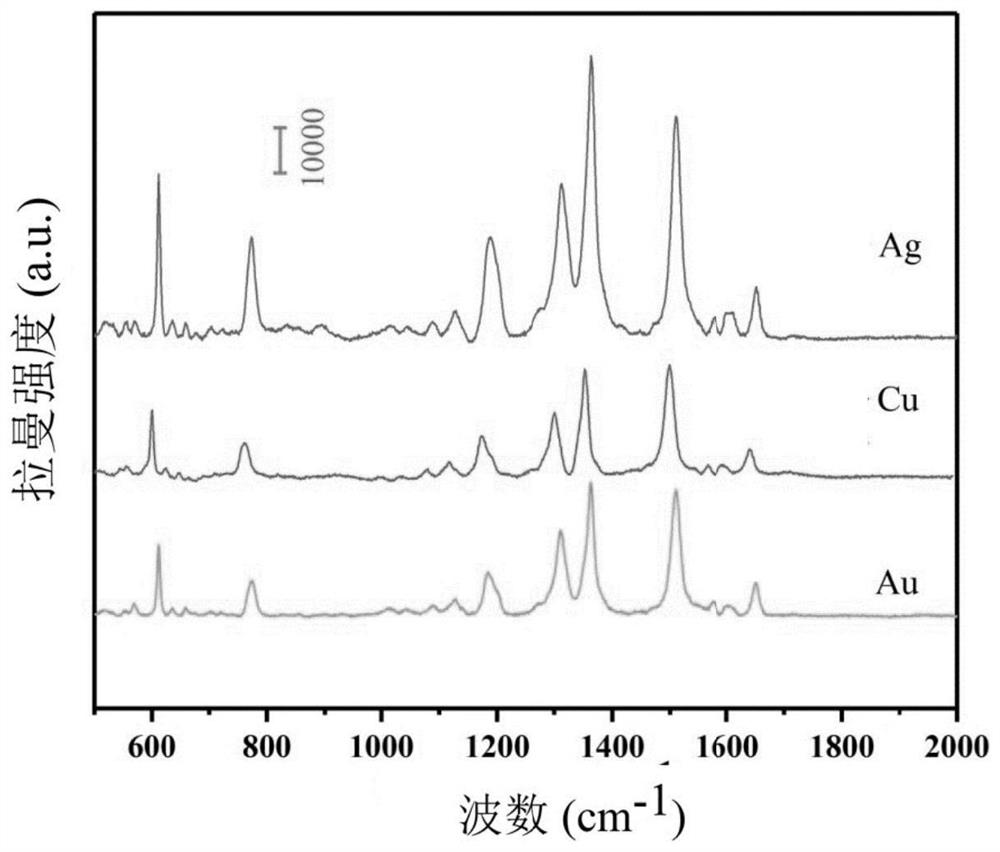

[0045]The theoretical calculation and simulation of picric acid solution in Example 4 uses Gaussion03 software.

Embodiment 1

[0047] Alkaline degreasing: configure NaOH (4wt%), Na 2 CO 3 (2wt%) solution of 100mL solution, a batch of 1cm x 3cm x 0.5cm titanium substrates were immersed in the solution, and ultrasonicated at 53kHz and 250W for 30min.

[0048] Oxalic acid etching: Rinse the titanium plate with clean water after degreasing and immerse it in a 20wt% oxalic acid solution to control the temperature of the solution at 98°C. After etching for 5 hours, take it out and clean it for later use.

[0049] Chemical growth of copper nanospheres: immerse the pretreated titanium plate in the prepared chemical deposition solution, including ammonium fluoride (8g / L), copper sulfate pentahydrate (20g / L), citric acid (20g / L ), sulfuric acid (0.8vol%), deposit at 20° C. for 3 minutes, take it out, clean it up, and dry it with nitrogen, and then prepare a titanium-based enhanced Raman substrate supported by copper nanospheres.

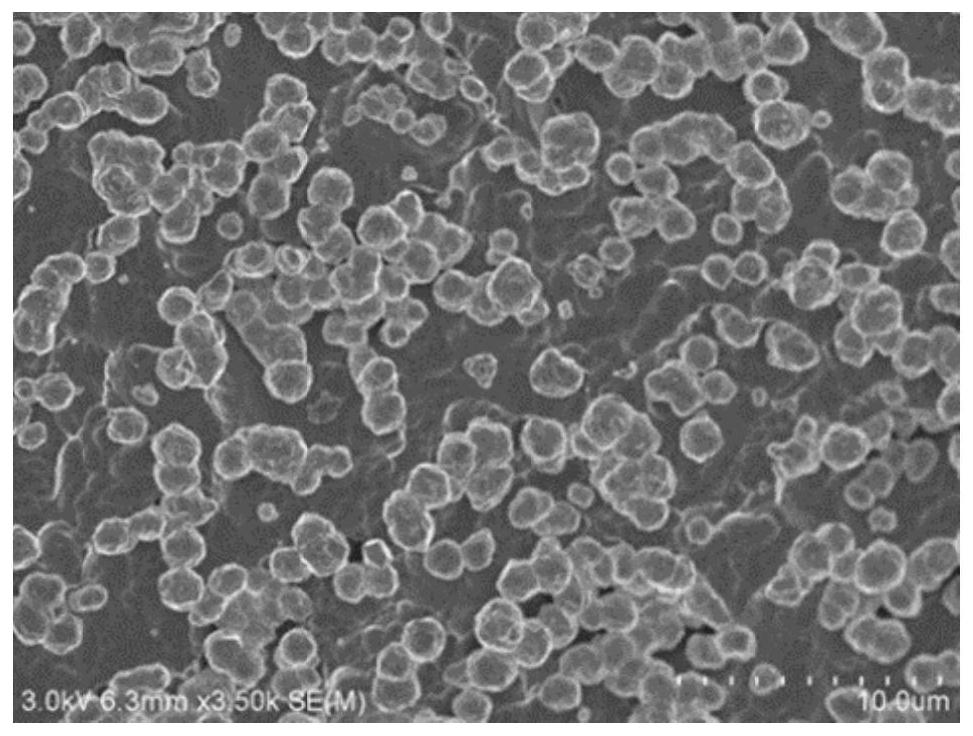

[0050] figure 1 It is a cold-field scanning electron microscope photo of the p...

Embodiment 2

[0053] Alkaline degreasing: 100mL solution of NaOH (10wt%) solution was prepared, a batch of 1cm×1cm×0.5cm titanium substrates were immersed in the solution, and ultrasound was performed at 53kHz and 250W for 1 hour.

[0054] Oxalic acid etching: Rinse the titanium plate with clean water after degreasing and immerse it in an oxalic acid (15wt%) solution to control the temperature of the solution to 98°C. After etching for 3 hours, take it out and clean it for later use.

[0055] Chemical growth of gold nanoflowers: immerse the pretreated titanium plate in the prepared chemical deposition solution, including ammonium fluoride (10g / L), chloroauric acid (1g / L), citric acid (20g / L) , hydrochloric acid (0.4vol%), deposited in a solution at 20° C. for 2 minutes, took it out and cleaned it, and dried it with nitrogen gas, so that the titanium-based enhanced Raman substrate supported by gold nanoflowers was prepared.

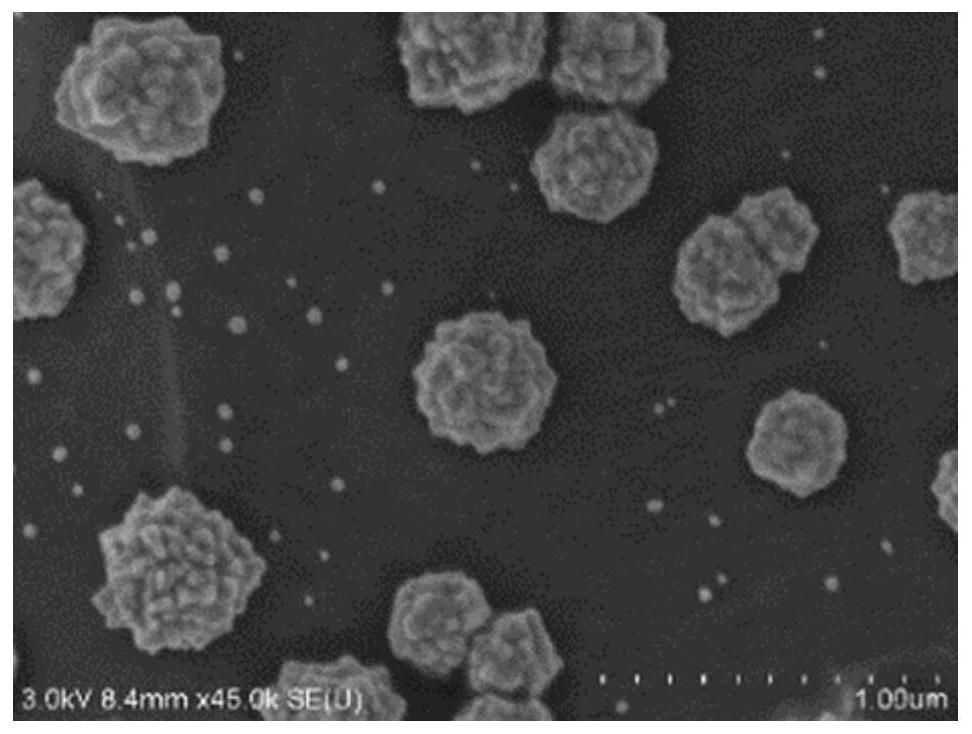

[0056] image 3 It is a cold-field scanning electron microscope p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com