Preparation method and application of hierarchical porous nickel-based metal-organic framework electrocatalytic materials

A technology of hierarchical porous and electrocatalytic materials, applied in electrodes, electrolytic components, electrolytic processes, etc., can solve problems such as low conductivity, failure to meet industrial production standards, and unsatisfactory nano-morphology, and achieve low production costs and excellent Electrocatalytic performance, the effect of realizing electron transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

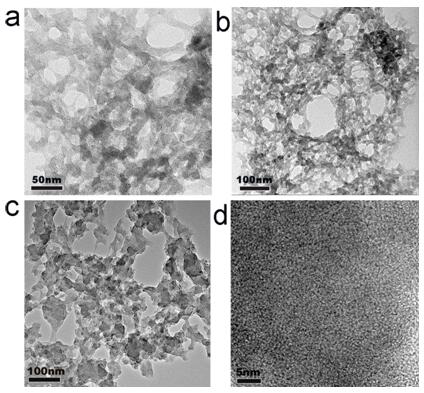

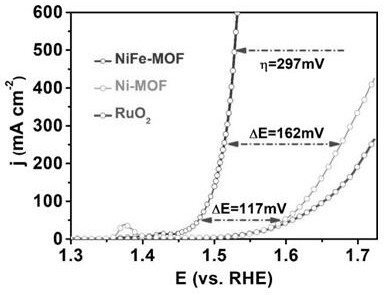

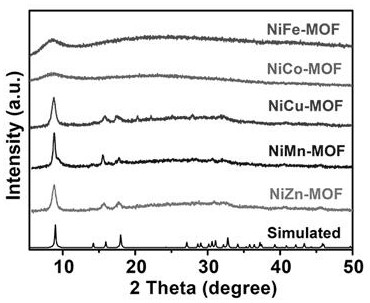

[0032] Example 1: Preparation of NiFe-MOF Oxygen Evolution Catalyst

[0033] Weigh 80 mg of 1,4-terephthalic acid powder and dissolve it in a mixed solvent composed of 16mL N,N dimethylformamide and 8mL acetonitrile, stir and dissolve at room temperature for 2h to obtain solution A; measure 8mL N , N dimethylformamide and 8mL acetonitrile, stirred at room temperature for 2h to obtain solution B; weigh appropriate amount of nickel acetate tetrahydrate and ferrous acetate and dissolve them in 8mL N, N dimethylformamide and 16mL acetonitrile In the mixed solvent, stir well at room temperature for 2 h to obtain solution C. Then, during the stirring process, take 3mL of solution A and drop it into the bottom of the glass bottle, take 2mL of solution B and put it on the upper layer of solution A to form the intermediate layer solution, take 3mL of solution C on the upper layer of solution B, and place the glass bottle that has been clearly stratified Under low temperature environme...

Embodiment 2

[0034] Example 2: Preparation of NiCo-MOF Oxygen Evolution Catalyst

[0035] Weigh 80 mg of 1,4-terephthalic acid powder and dissolve it in a mixed solvent composed of 16mL N,N dimethylformamide and 8mL acetonitrile, stir and dissolve at room temperature for 2h to obtain solution A; measure 8mL N , N dimethylformamide and 8mL acetonitrile, stirred at room temperature for 2h to obtain solution B; weigh appropriate amount of nickel acetate tetrahydrate and cobalt acetate tetrahydrate and dissolve them in 8mL N, N dimethylformamide and 16mL acetonitrile to form In the mixed solvent of , fully stirred at room temperature for 2 h to obtain solution C. Then, during the stirring process, take 3mL of solution A and drop it into the bottom of the glass bottle, take 2mL of solution B and put it on the upper layer of solution A to form the intermediate layer solution, take 3mL of solution C on the upper layer of solution B, and place the glass bottle that has been clearly stratified Und...

Embodiment 3

[0036] Embodiment 3: Preparation of NiCu-MOF oxygen evolution catalyst

[0037] Weigh 80 mg of 1,4-terephthalic acid powder and dissolve it in a mixed solvent composed of 16mL N,N dimethylformamide and 8mL acetonitrile, stir and dissolve at room temperature for 2h to obtain solution A; measure 8mL N , N dimethylformamide and 8mL acetonitrile, stirred at room temperature for 2h to obtain solution B; weigh appropriate amount of nickel acetate tetrahydrate and copper acetate monohydrate and dissolve them in 8mL N,N dimethylformamide and 16mL acetonitrile to form In the mixed solvent of , fully stirred at room temperature for 2 h to obtain solution C. Then, during the stirring process, take 3mL of solution A and drop it into the bottom of the glass bottle, take 2mL of solution B and put it on the upper layer of solution A to form the intermediate layer solution, take 3mL of solution C on the upper layer of solution B, and place the glass bottle that has been clearly stratified Un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com