A kind of n-type high-efficiency battery positive silver-aluminum paste

A silver-aluminum paste, high-efficiency technology, applied in the field of materials, can solve the problems of insufficient overall electrical performance, poor printing performance, unstable electrical performance, etc., and achieve the effect of ensuring current conduction ability, promoting contact performance, and improving electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

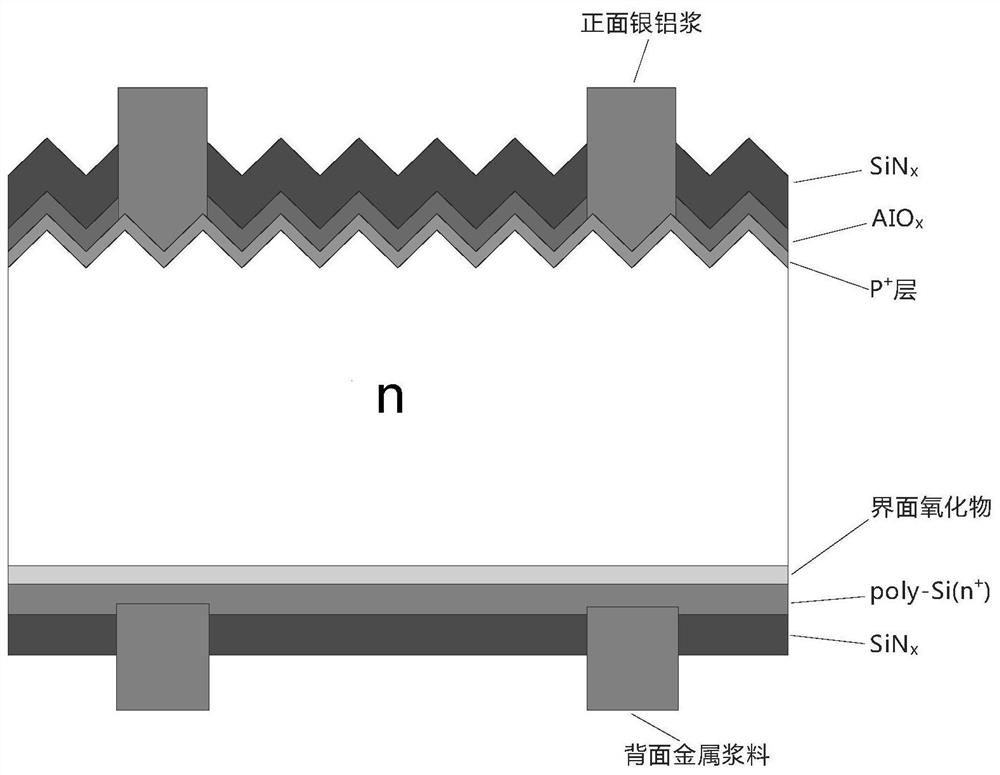

Image

Examples

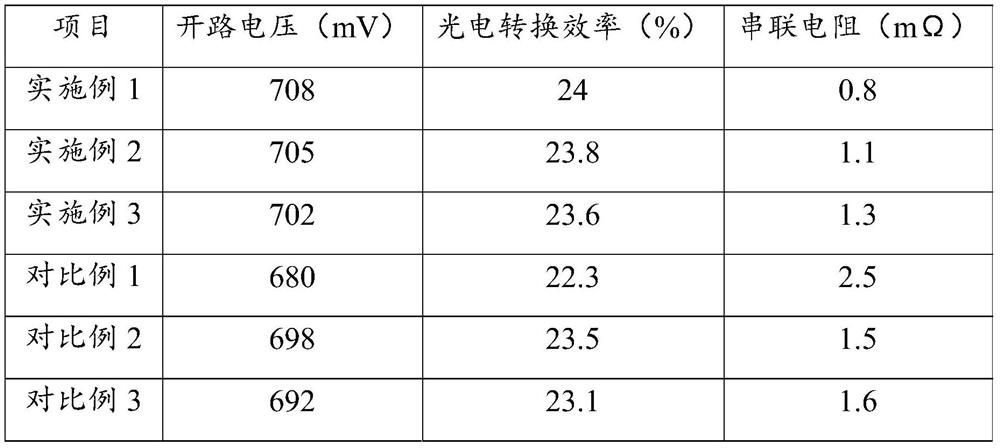

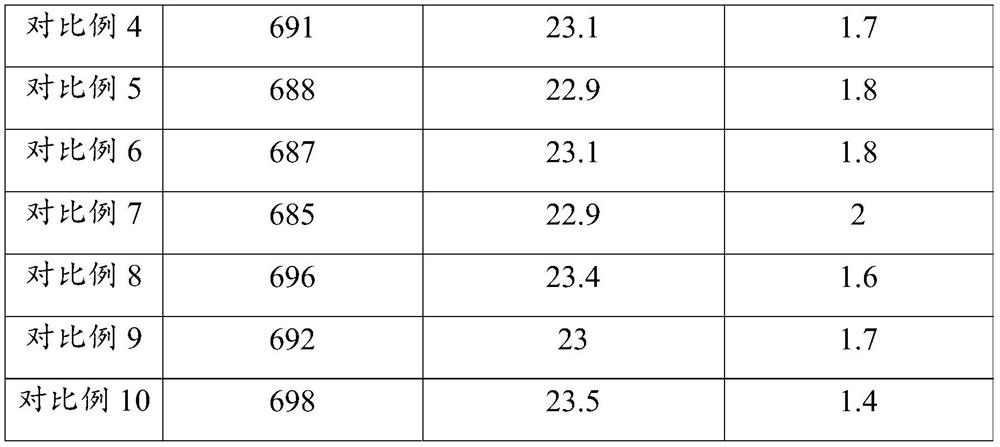

Embodiment 1

[0027] An embodiment of the n-type high-efficiency battery of the n-type high-efficiency battery according to the present invention, the n-type high-efficiency battery front silver aluminum paste, including the following parts: silver aluminum powder mixture 90 parts, glass 5 parts, a metal oxide, 8 parts of an organic support, 5 Alb alloys, 0.5 parts of boron powder, 0.5 parts of dispersant, 0.5 parts of the leveling agent and 0.5 parts of the thixotropic agent; the silver aluminum powder mixture included The mass ratio of categorous silver powder and aluminum powder, silver powder and aluminum powder is 1:80; the activity of the aluminum powder is 98.9%; the dispersant is a sorbitanhydride trihalate; the organic support includes the following weight. Component: Acrylic resin with 8 parts of ethylcellulose mixture, 15 copper alcohols, 20 servants of butyl carol, 20 parts of dihydrate, 19 cell phthalate, chitine 5 parts of alcohol butyl ether and 10 parts of ethylene glycid ether;...

Embodiment 2

[0037] An embodiment of the n-type high-efficiency battery of the n-type high-efficiency battery of the present invention, the n-type high-efficiency battery front silver aluminum paste, including the following parts: silver aluminum powder mixture 95 parts, glass 8 parts, 0.2 parts of metal oxide, 12 parts of the organic support, 10 parts of Alb alloy, 0.5 parts of boron powder, 1 part dispersant, 0.5 parts, 0.5 parts of the thixotropic agent; the silver aluminum powder mixture included The mass ratio of type spin silver powder and aluminum powder, silver powder and aluminum powder is 1: 78; the activity of the aluminum powder is 99%; the dispersant is a sorbitan trihalate; the ALB alloy is an Alb alloy. powder.

[0038] The median diameter of the spherical silver powder is 2.5 μm, the specific surface area is 2m 2 / g, the resonance density is 4g / m 3 The burnt rate is 0.5%; the median diameter of the aluminum powder is 4.5 μm, the maximum particle size D. 100 12 μm.

[0039] T...

Embodiment 3

[0045] An embodiment of the N-type high-efficiency battery of the n-type high-efficiency battery of the present invention, the n-type high-efficiency battery front silver aluminum paste, including the following parts: silver aluminum powder mixture 83 parts, glass 3, 0.05 parts of metal oxide, 4 parts of the organic support, 2 Alb alloys, 0.5 parts of boron powder, 0.5 parts of the dispersant, 0.5 parts, 0.5 parts of the thixotropic agent; the silver aluminum powder mixture included The mass ratio of categorous silver powder and aluminum powder, silver powder and aluminum powder is 1: 85; the activity of the aluminum powder is 99%; the dispersant is a sorbitan trihalate; the ALB alloy is an Alb alloy. powder.

[0046] The median diameter of the spherical silver powder is 0.5 μm, the specific surface area is 1m 2 / g, the resonance density is 6g / m 3 The burnt rate is 0.5%; the median diameter of the aluminum powder is 2 μm, the maximum particle size D 100 10 μm.

[0047] The frit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com