Preparation method of biomedical metal material loaded with multifunctional composite coating

A composite coating, biomedical technology, applied in the field of preparation of biomedical metal materials, can solve the problems of limited application, difficult combination, easy corrosion, etc., and achieve favorable growth and adhesion, good biocompatibility, and improved corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Choose Ti6Al4V titanium alloy, after grinding and polishing, immerse it in hydrofluoric acid solution, then take it out, wash it with acetone, ethanol and deionized water respectively, take it out and dry it, and immerse the sample in 0.05mg / ml polyethyleneimine solution Leave it for a period of time, take it out and dry it for later use. Preparation mass fraction is 10% regenerated silk fibroin (RSF) aqueous solution, concentration is the chitosan (CS) solution of 5mg / ml and the gelatin aqueous solution (GEL aqueous solution) of mass fraction 5%: Utilize sodium carbonate (Na 2 CO 3 ) aqueous solution to degumming the silk, dissolving the degummed silk in lithium bromide aqueous solution, centrifuging, filtering and dialysis to obtain regenerated silk fibroin aqueous solution, and concentrating it to 10% by mass. Take a certain amount of chitosan and dissolve it in 2vol.% acetic acid aqueous solution to prepare a chitosan solution with a concentration of 5 mg / ml. Diss...

Embodiment 2

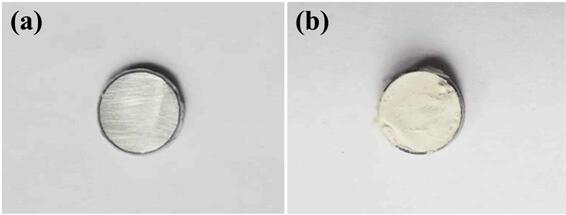

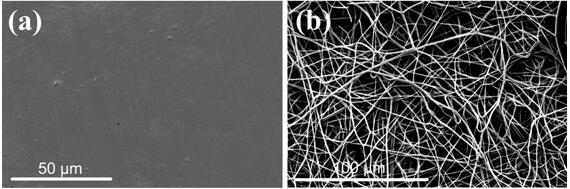

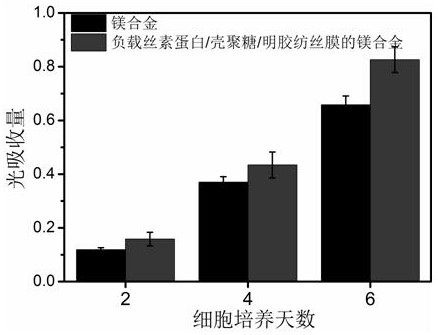

[0031] Choose AZ31B magnesium alloy, after grinding and polishing, dip it in hydrofluoric acid solution, then take it out, wash it with acetone, ethanol and deionized water respectively, take it out and dry it, and dip the sample in 10mg / ml polyethyleneimine solution After a period of time, take it out and dry it for later use. Prepare the RSF aqueous solution that the mass fraction is 15%, the CS solution that the concentration is 15mg / ml and the GEL solution of mass fraction 8%: Utilize sodium carbonate (Na 2 CO 3 ) aqueous solution to degumming the silk, dissolving the degummed silk in lithium bromide aqueous solution, centrifuging, filtering and dialysis to obtain regenerated silk fibroin aqueous solution, and concentrating it to 15% by mass. Take a certain amount of chitosan and dissolve it in 2vol.% acetic acid aqueous solution to prepare a chitosan solution with a concentration of 15mg / ml. Take a certain amount of gelatin and dissolve it in water to prepare an 8% gela...

Embodiment 3

[0033] Select stainless steel, after grinding and polishing, immerse it in hydrofluoric acid solution, then take it out, wash it with acetone, ethanol and deionized water respectively, take it out and dry it, and immerse the sample in 40mg / ml polyethyleneimine solution for a period of time , take out and dry for later use. Preparation mass fraction is 20% RSF aqueous solution, concentration is the CS solution of 25mg / ml and the GEL solution of mass fraction 10%: Utilize sodium carbonate (Na 2 CO 3 ) aqueous solution to degumming the silk, dissolving the degummed silk in lithium bromide aqueous solution, centrifuging, filtering and dialysis to obtain regenerated silk fibroin aqueous solution, and concentrating it to 20% by mass. Take a certain amount of chitosan and dissolve it in 2vol.% acetic acid aqueous solution to prepare a chitosan solution with a concentration of 25mg / ml. Take a certain amount of gelatin and dissolve it in water to prepare a 10% gelatin aqueous solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com