Soft ceramic tile and preparation method thereof

A ceramic tile and soil technology, applied in the field of soft ceramic tiles, can solve the problems of inability to coexist structural strength and flexibility, inability to improve air, and insufficient environmental performance, to prevent oxidation reaction and thermal decomposition, improve market application prospects, and improve air quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

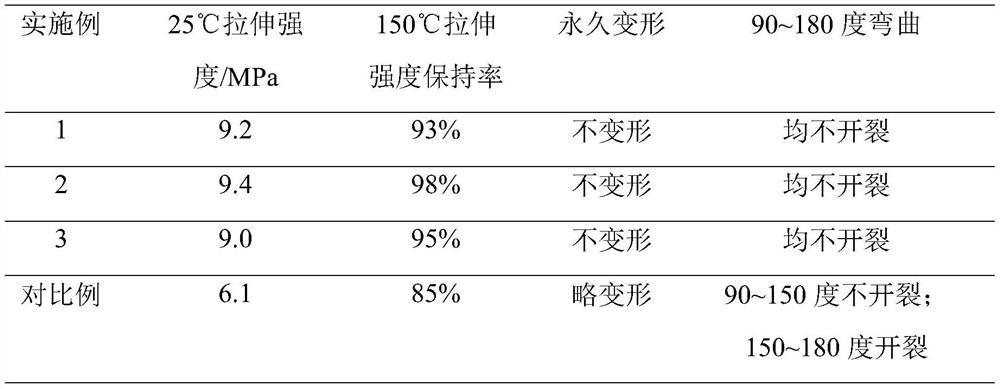

Examples

Embodiment 1

[0028] A soft tile made from the following raw materials:

[0029] 150 parts clay, 10 parts of straw, 2 parts of grapefruit peel, orange peel parts 1, 10 parts of activated carbon powder, 80 parts of the petals of water, 15 parts of coconut diethanolamide, 8 parts of sodium lauryl sulfate, 100 parts of magnetized water , 3 parts of iron oxide powder, 0.6 parts of silver particles, 2 parts of leavening agent, 6 parts of charcoal particles, 2 parts of zinc borate.

[0030] The method of preparing a soft tile, comprising the steps of:

[0031] A, respectively, parts by weight of the above-described take straw, grapefruit and orange peel skin mixing, chopping, at a heating rate of 1 ℃ / min temperature was raised to 40 ℃, heat 6h, then at a heating rate of 1.5 ℃ / min was heated to 55 ℃, heat 3h Finally, at a heating rate of 1 ℃ / min temperature was raised to 80 ℃, heat 3h, pulverization, the mixed powders have to deal with;

[0032] B, according to the above-mentioned parts by weigh...

Embodiment 2

[0044]A soft parcel brick, made of raw materials:

[0045] 155 mud, 13 straw, 3 grapefruit skin, 2 orange peel, 11 active carbon powder, 85 pieces of water petals, 18 parts of methacolate, 9 parts of sodium sulfate, 102 parts of magnetization water 4 serial ferrous particles, 2.5 parts of the fermented agent, 6.5 parts of bamboo charcoal particles, 3 parts of boronate.

[0046] The preparation method of the soft tile includes the following steps:

[0047] A. Mix the straw, grapefruit and orange peel, chopped in the above weight parts, chopped, tapered to heat up at a temperature rise rate of 1 ° C / min to 43 ° C, heat the temperature of 1.5 ° C / min, and warmed to 57 ° C, heat insulation for 3h Finally, the temperature increased at 1 ° C / min to 83 ° C, heat insulation for 3 h, pulverized, and the mixed powder was obtained;

[0048] B. According to the weight parts described above, the above weight of the weight of magnetized water, a fermented agent, a fermented agent, a ferme...

Embodiment 3

[0060] A soft parcel brick, made of raw materials:

[0061] 160 mud, 15 straw, 4 grapefruit skin, 3 orange peel, 12 active carbon powder, 90 pieces of water, 20 servile diethanolamide, 10 parts of sodium sulfate, 105 parts of magnetization 5 parts of the three ferrous dioxide powder, 0.8 copies of silver particles, 3 servants, 7 part bamboo charcoal particles, zinc boricate.

[0062] The preparation method of the soft tile includes the following steps:

[0063] A. Mix the straw, grapefruit, and orange peel, chopped in the above weight parts, chopped to heat up to 45 ° C at 1 ° C / min, and warm up at a temperature of 1.5 ° C / min to 10 ° C, heat insulation 3h Finally, it was raised to 85 ° C at 1 ° C / min to 85 ° C, heat insulation for 3 h, pulverized, and the mixed powder was obtained;

[0064] B, according to the above weight parts, the above-mentioned weight of magnetized water, a fermented agent, sodium dodecyl sulfate, stir mixing is added, and it is placed in 70 ° C for 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com