Steel structure self-isolation type anti-corrosion process

A steel structure, isolation technology, applied in metal material coating process, coating and other directions, can solve the problems of poor performance of anti-corrosion coating, corrosion, etc., to achieve the goal of not being easy to scratch and impact cracks, avoiding erosion, and avoiding diffusion erosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

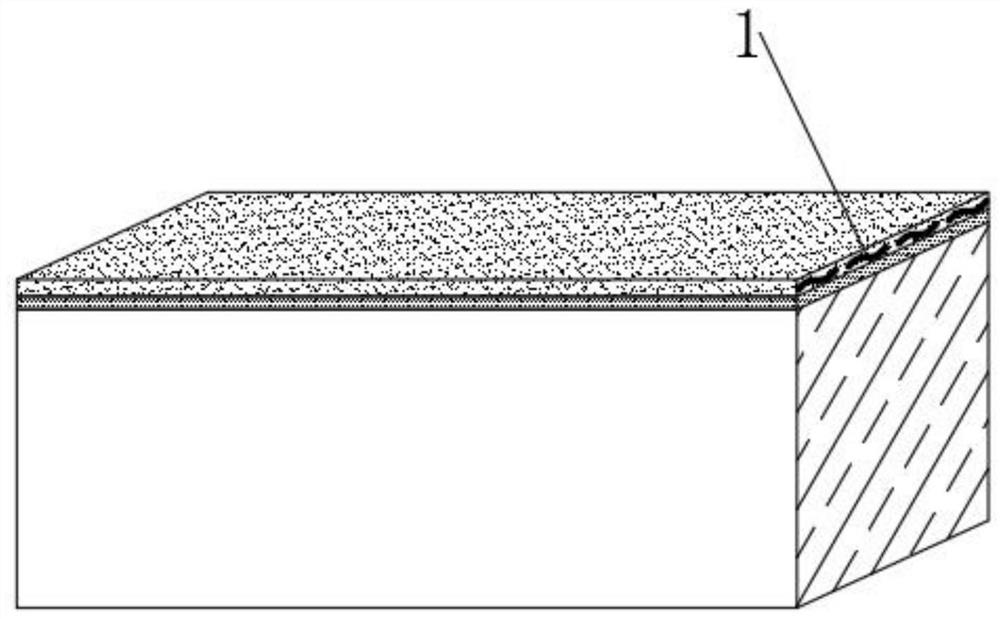

[0042] see figure 1 , a self-isolated anticorrosion process for steel structures, comprising the following steps:

[0043] S1. Use mechanical treatment or chemical treatment to remove rust, oil and pollutants on the surface of the steel structure, and preheat to 150°C;

[0044] S2. Feed the metallurgical powder into the cladding pool, and form a uniform and dense laser cladding coating on the surface of the steel structure by means of scanning cladding;

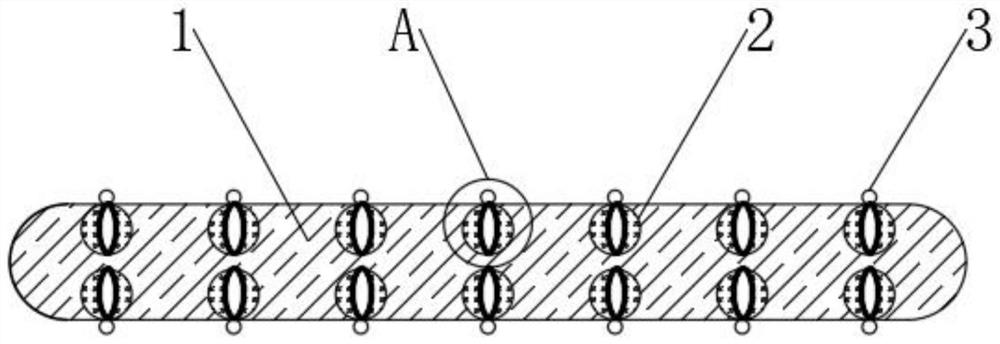

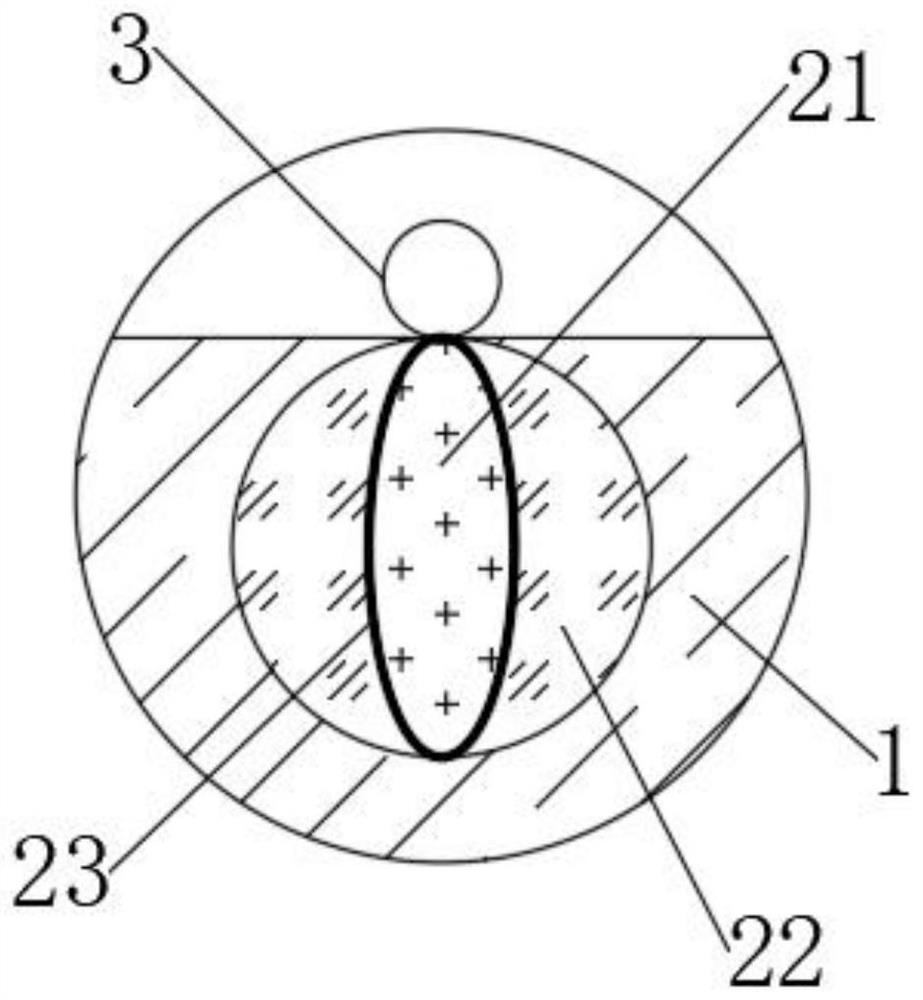

[0045] S3. After cladding, keep warm at 140°C. When the laser cladding coating is not completely cured, prepare anti-corrosion coatings and evenly mix them into self-isolation reinforcing tubes 1 at a density of 1 piece / 10ml;

[0046] S4. Coating an anti-corrosion coating on the laser cladding coating, and then solidifying at room temperature to form an isolation layer.

[0047] Further, in step S1, the surface of the steel structure is ground to ST2 level, and the surface roughness Rz is 60-80 μm.

[0048] The laser proce...

Embodiment 2

[0057] see figure 1 , a self-isolated anticorrosion process for steel structures, comprising the following steps:

[0058] S1. Use mechanical treatment or chemical treatment to remove rust, oil and pollutants on the surface of the steel structure, and preheat to 180°C;

[0059] S2. Feed the metallurgical powder into the cladding pool, and form a uniform and dense laser cladding coating on the surface of the steel structure by means of scanning cladding;

[0060] S3. After cladding, keep warm at 160°C. When the laser cladding coating is not completely cured, prepare anti-corrosion coatings and evenly mix them into self-isolation reinforcing tubes 1 at a density of 1 piece / 10ml;

[0061] S4. Coating an anti-corrosion coating on the laser cladding coating, and then solidifying at room temperature to form an isolation layer.

[0062] In step S1, the surface of the steel structure is ground to ST2 level, and the surface roughness is Rz60-80 μm.

[0063] The laser process paramet...

Embodiment 3

[0068] see figure 1 , a self-isolated anticorrosion process for steel structures, comprising the following steps:

[0069] S1. Use mechanical treatment or chemical treatment to remove rust, oil and pollutants on the surface of the steel structure, and preheat to 200°C;

[0070] S2. Feed the metallurgical powder into the cladding pool, and form a uniform and dense laser cladding coating on the surface of the steel structure by means of scanning cladding;

[0071] S3. After cladding, keep warm at 180°C. When the laser cladding coating is not completely cured, prepare anti-corrosion coating and evenly mix it with self-isolation reinforcing tube 1 at a density of 1 piece / 10ml;

[0072] S4. Coating an anti-corrosion coating on the laser cladding coating, and then solidifying at room temperature to form an isolation layer.

[0073] In step S1, the surface of the steel structure is ground to ST2 level, and the surface roughness is Rz60-80 μm.

[0074] The laser process parameters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com