Preparation method and application of calcium glycerophosphate

A technology of calcium glycerophosphate and glycerophosphate, applied in the directions of application, chemical instruments and methods, phosphorus organic compounds, etc., can solve the problems of no way to recycle the mother liquor, no way to industrialize production, low recovery rate of organic solvents, etc. Moderate performance, low equipment requirements, good absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

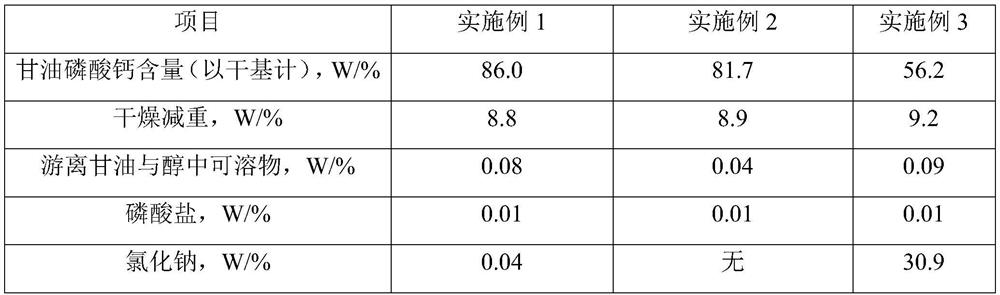

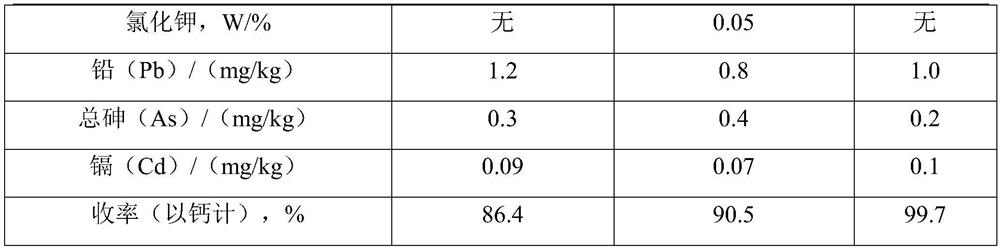

Embodiment 1

[0046] A preparation method of calcium glycerophosphate, comprising the steps of:

[0047] Turn on stirring, at 10m 3 Add 4t of water into the reaction kettle, add 925.6kg of sodium glycerophosphate with a purity of 98%, stir and dissolve, then add 467.4kg of calcium chloride with a purity of 95%, and after heating up to 50°C, use glutamic acid to control the pH throughout the process value to 10, stirred and reacted for 1.5h to make it fully reacted, filtered while hot, washed several times to desalinate, added 4% of wet material weight modified starch, granulated, and then dried in a fluidized bed to obtain glycerol phosphate The calcium product is about 844kg. Then screen out 5-10 mesh products (products with unqualified mesh number, re-grind and add to the next batch of wet materials for granulation).

Embodiment 2

[0049] A preparation method of calcium glycerophosphate, comprising the steps of:

[0050] Turn on stirring, at 5m 3 Add 2t of water into the reaction kettle, add 1.02t of potassium glycerophosphate with a purity of 98%, stir and dissolve, then add 467.4kg of calcium chloride with a purity of 95%, after heating up to 80°C, use glutamic acid to control the pH throughout the process When the value reaches 8.1, stir and react for 40 minutes to make it fully react, filter while hot, add 7% dextrin of wet material weight, granulate, and then dry in a fluidized bed to obtain about 931kg of calcium glycerophosphate product. Then screen out 80-120 mesh products (products with unqualified mesh number, re-grind and add to the next batch of wet materials for granulation).

Embodiment 3

[0052] A preparation method of calcium glycerophosphate, comprising the steps of:

[0053] Turn on stirring, at 5m 3 Add 1.5t of the mother liquor in Example 1 in the reaction kettle, add 863.9kg sodium glycerophosphate with a purity of 98%, after stirring and dissolving, add 467.4kg of calcium chloride with a purity of 95%, and heat up to 100°C. Control the pH value of glutamic acid to 7 throughout the whole process, stir and react for 10 minutes to make it fully react, filter while it is hot, add 10% cyclodextrin by weight of wet material, granulate, and then dry in a fluidized bed to obtain calcium glycerophosphate The product is about 1.5t. Then screen out 30-60 mesh products (products with unqualified mesh number, re-grind and add to the next batch of wet materials for granulation).

[0054] The mother liquor contains calcium glycerophosphate and sodium chloride, which are recycled for the next batch of reactions; the number of times of recycling is not limited.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com