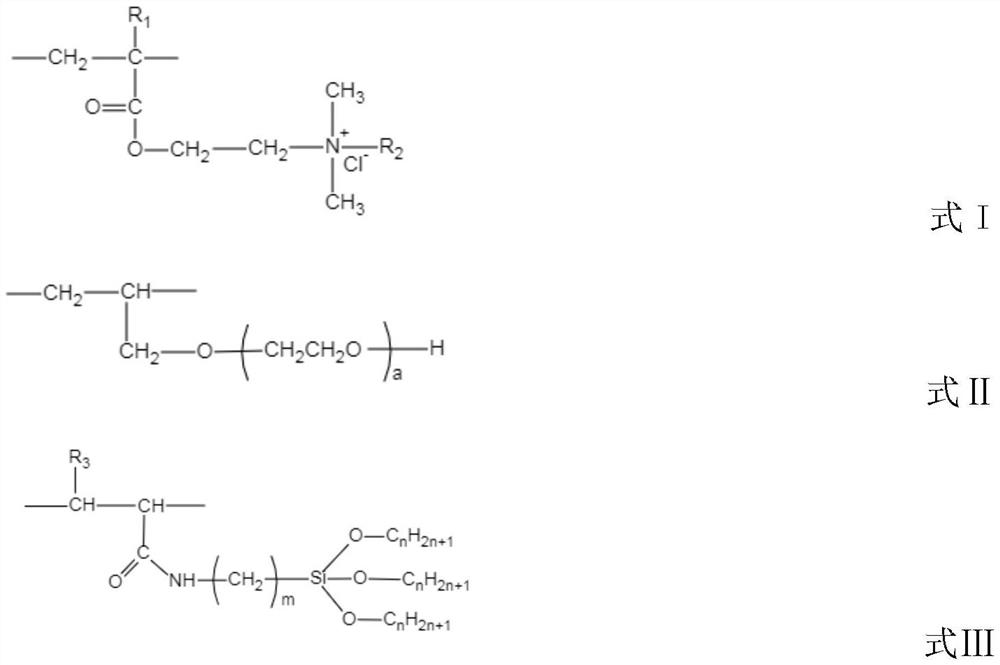

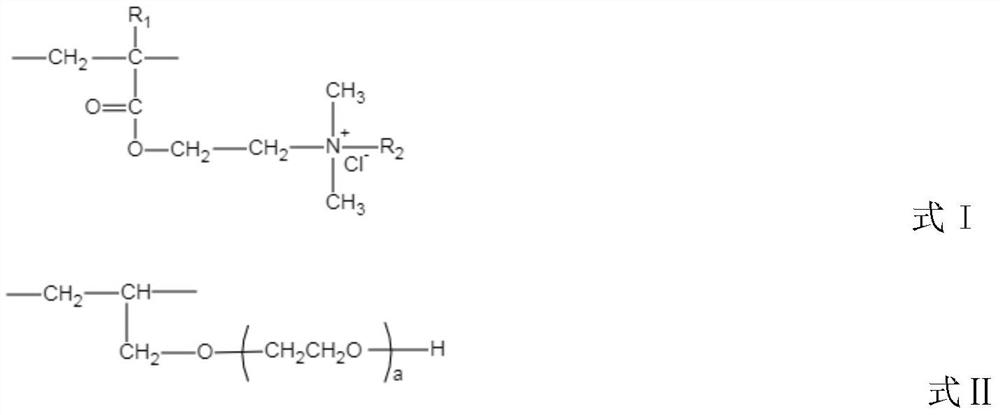

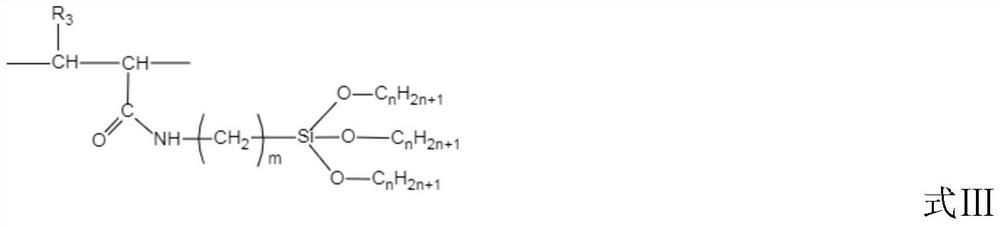

Water-based organic silicon color fixing agent polymer and preparation method thereof

A technology of silicone and color-fixing agent, applied in dyeing, textile and papermaking, etc., can solve the problems of destroying the hydrophilicity of the main chain structure, reducing the effect of waterproof and oil-repellent agent, and deteriorating the hydrophilicity of fabrics. and excellent hydrophilicity, preventing the deterioration of hydrophilicity, and improving the feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] In a particularly preferred embodiment, the preparation method of the water-based silicone color fixing agent of the present invention comprises the following steps:

[0051] 1) 0°C, add unsaturated carboxylic acid represented by formula VII, carbonyldiimidazole, and aprotic polar organic solvent (such as DMF) into the reactor, react for 0.5-1h, and then add aminoalkyltrialkoxy represented by formula VIII base silane, heated to 20-30°C, and reacted for 10-12h to obtain the organosilicon monomer represented by formula VI;

[0052] 2) Add cationic surfactant and water to step 1), stir and emulsify at room temperature 800-1000r / min for 1-2h;

[0053] 3) Add the cationic monomer represented by formula IV, the allyl polyoxyethylene ether monomer represented by formula V and deionized water to step 2), raise the temperature to 70-80 ° C, drop a free radical initiator (such as persulfuric acid Ammonium aqueous solution), initiates polymerization reaction, and 1-3 hour dropwise ...

Embodiment 1

[0078] 1) Control the temperature at 0°C, add 3.2g cinnamic acid (0.022mol), 3.6g carbonyldiimidazole (0.022mol), and 20g DMF into a four-neck flask equipped with a stirrer and a thermometer, react for 0.6h, and then add 4.3 g aminopropyltrimethoxysilane (0.024mol), heated to 20-30°C, reacted for 11h;

[0079] 2) Add 3g of dodecyldimethylbenzyl ammonium chloride and 5g of water to step 1), and stir at room temperature at 800r / min for 1h;

[0080] 3) Add 45g of acryloyloxyethyltrimethylammonium chloride (80%; 0.186mol) and 8g of allyl polyoxyethylene ether (a=40; 0.0044mol) to step 2), purchased from Shanghai Taijie Chemical Co., Ltd. company) and 15g deionized water, after stirring for 10min at 75°C, start to add 1% ammonium persulfate aqueous solution dropwise, and the dropwise addition ends after 1.5h;

[0081] 4) Raise the temperature to 80° C. and keep it warm for 3 hours to prepare the water-based silicone color fixing agent 1. The weight-average molecular weight of the...

Embodiment 2

[0083] 1) Control the temperature at 0°C, add 2.6g of crotonic acid (0.03mol), 4.86g of carbonyldiimidazole (0.03mol), and 20g of DMF into a four-neck flask equipped with a stirrer and a thermometer, react for 1 hour, and then add 7.08g Aminopropyltriethoxysilane (0.032mol), heated to 20-30°C, reacted for 10-12h;

[0084] 2) Add 3g of dodecyldimethylbenzyl ammonium chloride and 5g of water to step 1), and stir at room temperature at 800r / min for 1h;

[0085] 3) Add 80g of methacryloxyethyl dimethyl benzyl ammonium chloride (60%; 0.17mol) and 6.9g of allyl polyoxyethylene ether (a=30; 0.005mol) to step 2), purchased from Shanghai Taijie Chemical Co., Ltd.) and 5g deionized water, after stirring at 80°C for 10min, start to add 1% aqueous solution of ammonium persulfate dropwise, and the dropwise addition ends after 2h;

[0086] 4) Raise the temperature to 85° C. and keep it warm for 2 hours to prepare the water-based silicone color fixing agent 2. The weight-average molecular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com