Phosphorus-nitrogen-silicon-containing titanium dioxide hybrid nanoparticle flame retardant as well as preparation method and application thereof

A technology of hybrid nanoparticles and titanium dioxide, applied in the field of flame retardants, can solve the problems of low flame retardant efficiency and poor dispersion, and achieve the effects of improving flame retardant performance, increasing mechanical properties and suppressing combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

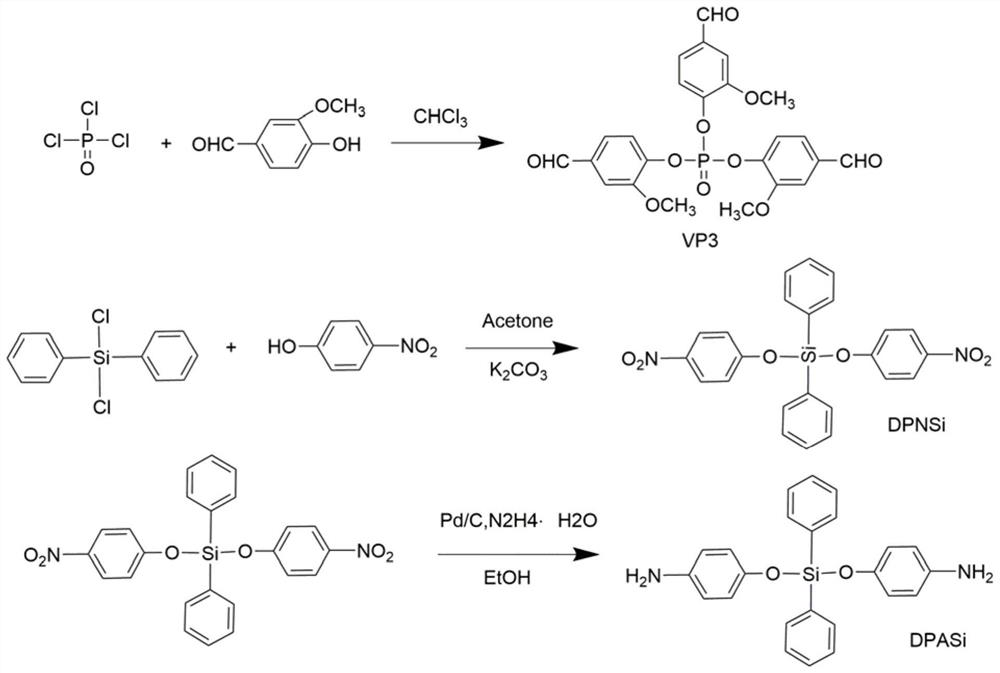

[0043] ①Preparation of VP3: Put 2.6g of vanillin in 50mL of analytically pure first solvent chloroform, then add 2mL of triethylamine and slowly add 0.90g of phosphorus oxychloride dropwise, stir for 2h, then heat up to 50°C for 9 hours , after cooling to room temperature, pour 200mL of petroleum ether, stir for half an hour after the white precipitate is precipitated, wash with ethanol several times, and then filter to obtain a white solid; the obtained solid is vacuum-dried at 70°C to constant weight to obtain a white powder, which is The resulting phosphorous-containing VP3;

[0044] ②Preparation of DPASi: Dissolve 2g of dichlorodiphenylsilane in 30mL of the second solvent acetone, slowly add it dropwise to 50mL of 2.18g of K 2 CO 3 and 2.32g of p-nitrophenol in acetone, the second solvent, reflux, condense and heat to 45°C, react for 48h, filter the reaction solution with suction to obtain a solid filter cake, wash the filter cake with deionized water and the second solve...

Embodiment 2

[0048] ①Preparation of VP3: Put 2.6g of vanillin in 50mL of analytically pure first solvent chloroform, then add 2mL of triethylamine and slowly add 0.90g of phosphorus oxychloride dropwise, stir for 2h, then heat up to 50°C for 9 hours , after cooling to room temperature, pour 200mL of petroleum ether, stir for half an hour after the white precipitate is precipitated, wash with ethanol several times, and then filter to obtain a white solid; the obtained solid is vacuum-dried at 70°C to constant weight to obtain a white powder, which is The resulting phosphorous-containing VP3;

[0049] ②Preparation of DPASi: Dissolve 2g of dichlorodiphenylsilane in 30mL of the second solvent acetone, slowly add it dropwise to 50mL of 2.18g of K 2 CO 3 and 2.32g of p-nitrophenol in acetone, the second solvent, reflux, condense and heat to 45°C, react for 48h, filter the reaction solution with suction to obtain a solid filter cake, wash the filter cake with deionized water and the second solve...

Embodiment 3

[0053] ①Preparation of VP3: Put 2.6g of vanillin in 50mL of analytically pure first solvent chloroform, then add 2mL of triethylamine and slowly add 0.90g of phosphorus oxychloride dropwise, stir for 2h, then heat up to 50°C for 9 hours , after cooling to room temperature, pour 200mL of petroleum ether, stir for half an hour after the white precipitate is precipitated, wash with ethanol several times, and then filter to obtain a white solid; the obtained solid is vacuum-dried at 70°C to constant weight to obtain a white powder, which is The resulting phosphorous-containing VP3;

[0054] ②Preparation of DPASi: Dissolve 2g of dichlorodiphenylsilane in 30mL of the second solvent acetone, slowly add it dropwise to 50mL of 2.18g of K 2 CO 3 and 2.32g of p-nitrophenol in acetone, the second solvent, reflux, condense and heat to 45°C, react for 48h, filter the reaction solution with suction to obtain a solid filter cake, wash the filter cake with deionized water and the second solve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com