Heat-compensated superheated steam coal upgrading system with temperature difference power generation

A technology of superheated steam and thermoelectric power generation, applied in the directions of steam superheating, steam generation, steam generation method, etc., to achieve the effect of reducing superheated steam consumption, huge technical value, efficient work and power generation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

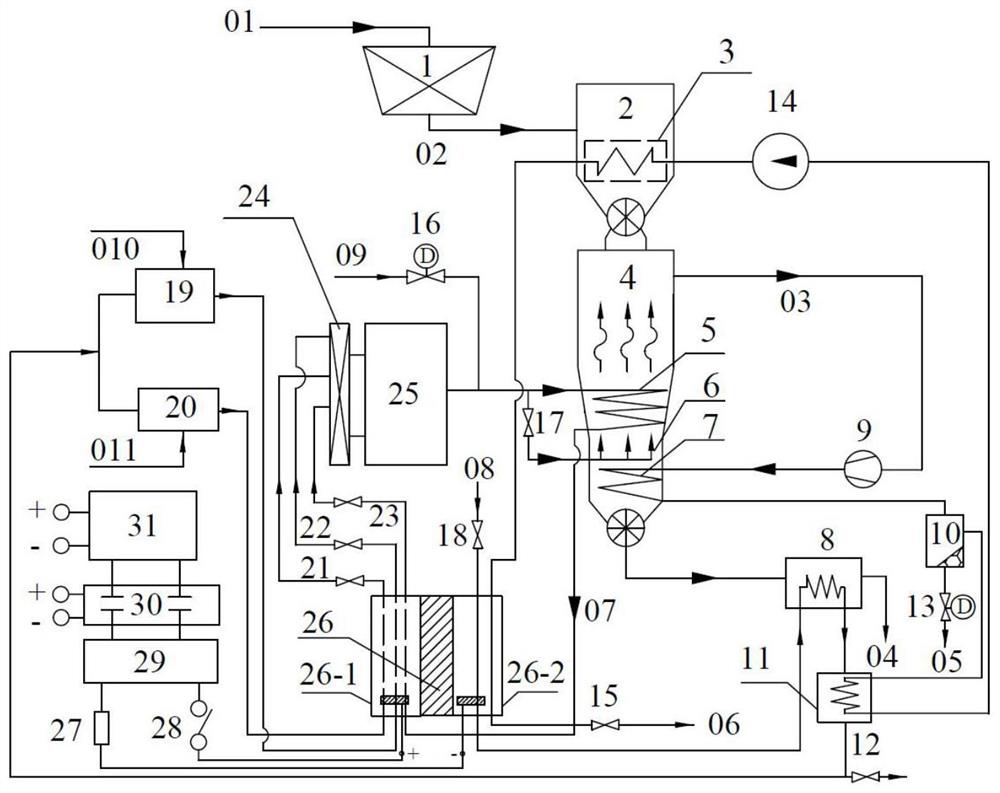

[0023] Thermally compensated superheated steam coal upgrading system with temperature difference power generation, including coal crusher 1, coal bunker 2, fluidized bed 4, coal cooler 8, circulation fan 9, dust collector 10, sludge discharge electric door 13, temperature difference Generator precipitation water outlet door 15, superheated steam electric door 16, nozzle inlet door 17, water supply door 18, waste heat heat exchanger 19, solar heat exchanger 20, mixing header 24, electric superheated steam generator 25, temperature difference generator Electrical appliance 26, high temperature side 26-1 of thermoelectric generator, low temperature side 26-2 of thermoelectric generator, internal resistance 27 of thermoelectric generator, switch 28 of thermoelectric generator, controller 29, battery pack 30, inverter 31;

[0024]The coal crusher 1 is connected to the coal bunker 2, and the coal bunker 2 is connected to the feed port of the fluidized bed 4. In the fluidized bed 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com