Engineering bacterium for producing heterologous alkaline protease and construction method thereof

A technology of protease and genetically engineered bacteria, applied in the field of microbial genetic engineering, can solve problems such as low expression level and unstable expression system, and achieve the effect of increasing expression level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A strain of genetically engineered bacteria producing heterologous alkaline protease and its construction method.

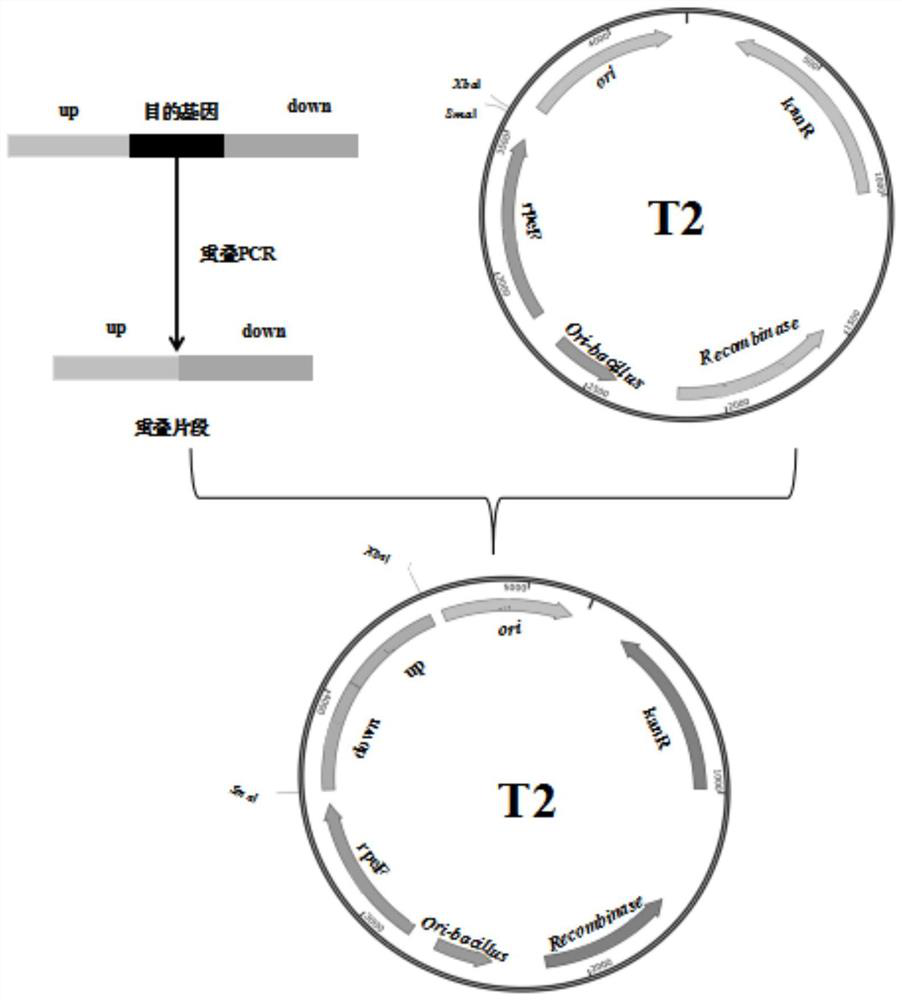

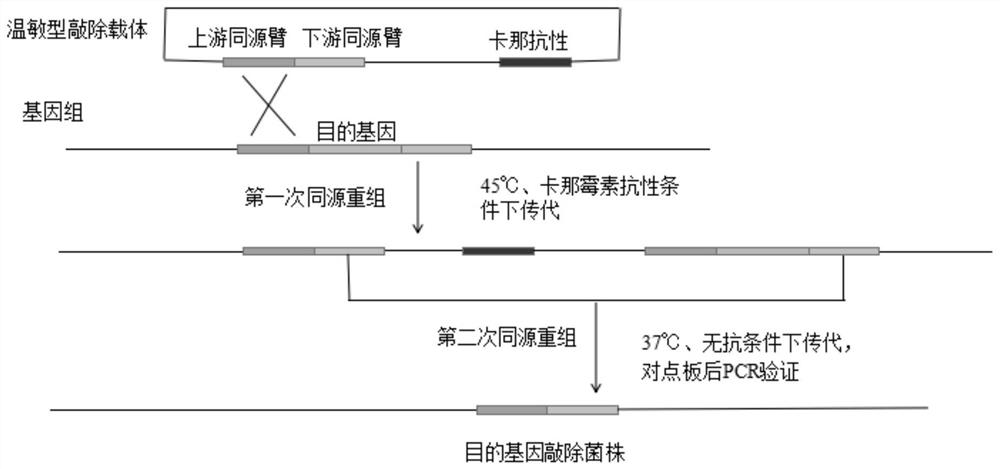

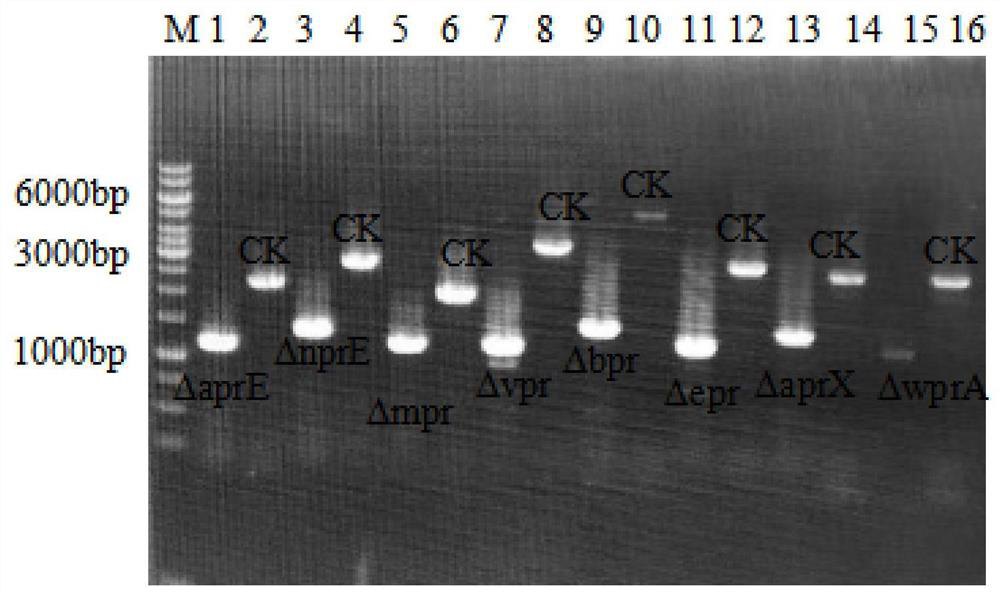

[0059] 1. Obtaining overlapping fragments of the homology arms of the knockout gene (taking epr as an example).

[0060] According to the whole genome sequence information of Bacillus amyloliquefaciens, taking the epr gene as an example, the primers for the upstream and downstream homology arms of epr were designed by SnapGene, and the target fragment was amplified by PCR, and the amplified upstream and downstream homology arm fragments were purified and recovered. Overlap PCR was performed using the recovered product as a template. The primer sequences and restriction sites used are shown in Table 1.

[0061] The reaction system used to amplify the Epr homology arm is 50 μL, as follows:

[0062]

[0063] The annealing temperature of Epr is 56°C, and the extension time corresponds to the length of the gene. The reaction procedure is as follows:

[006...

Embodiment 2

[0111] Expression and analysis of heterologous alkaline protease genetically engineered bacteria.

[0112] Inoculate single colonies of recombinant strains J1, J2, and J3 on fresh LB plates into 50 mL of kanamycin sulfate-resistant seed medium, culture with shaking at 37°C and 220 r / min for 12 hours, and transfer to 2% inoculum Inoculated in the fermentation medium containing kanamycin resistance, fermented and cultured at 37°C and 220r / min for 48h.

[0113] According to the national standard GB / T 23527-2009 Appendix B, the activity of alkaline protease in the fermentation supernatant of the recombinant strains was determined by the Folin phenol method, and the activity of alkaline protease in the fermentation supernatants of the three recombinant strains reached the highest at 48 hours , the recombinant alkaline protease activity expressed by the recombinant strain J3 reached 19524U / mL, which was 1.40 times that of the recombinant strain J1 (enzyme activity was 13985U / mL) and...

Embodiment 3

[0115] Scale-up experiment of recombinant alkaline protease genetically engineered bacteria.

[0116] Pick a single colony of recombinant bacteria on the plate and inoculate it into 100 mL of LB liquid medium containing 50 μg / mL kanamycin at 37°C and 220 r / min. After culturing for 4 hours, transfer to 100mL fermentation medium with 2% inoculum amount, 37°C, 220r / min, and after 8 hours of cultivation, transfer to 5L with a total volume of 3L with 2% inoculum amount Scale-up experiments were carried out in fermenters. Wherein, the dissolved oxygen content in the fermenter is controlled to be more than 40% during the fermentation process, the stirring speed is 600-700rpm, and the temperature is 37°C. When pH=7, feed (feed medium: cottonseed protein 50g / L, dextrin 300g / L), the initial feeding amount was 100g / h, and the DE value was controlled by feeding during the entire fermentation period to 15mg / mL-18mg / mL. In the early stage of fermentation, antifoaming agent is added approp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com