Super-amphiphobic stainless steel wire mesh and preparation process and application thereof

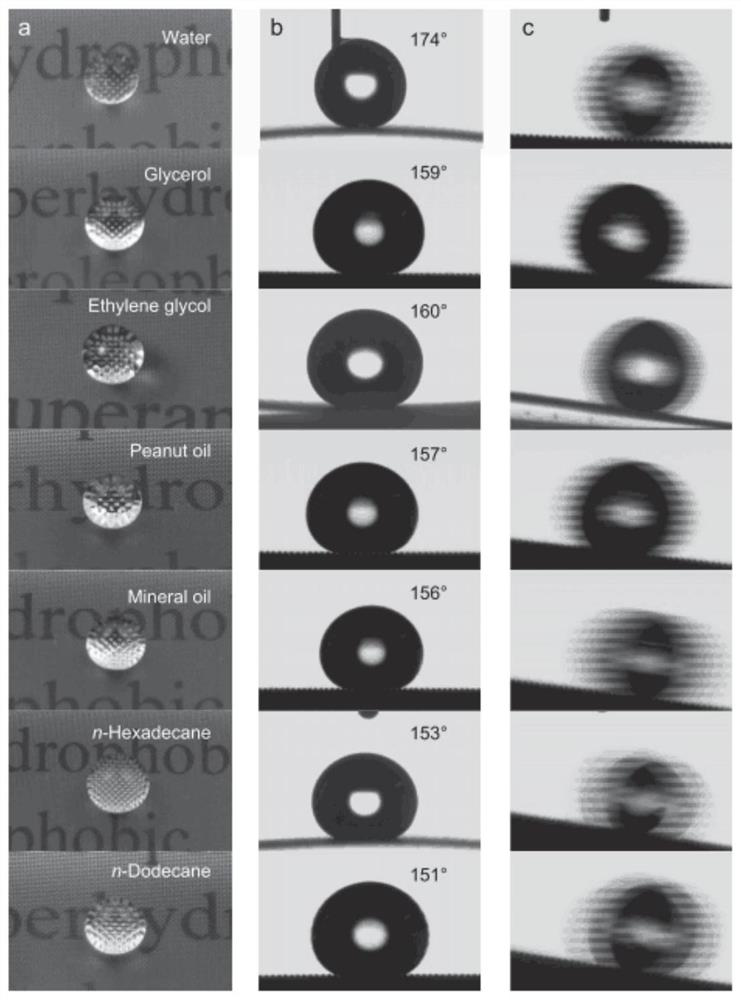

A preparation process, stainless steel technology, applied in metal material coating process, biochemical equipment and methods, artificial cell constructs, etc., can solve the problem that cannot meet the requirements of forward cultivation of large-sized multicellular spheres, super-amphiphobic surface machinery Poor stability, complex multi-level structure design process and other problems, to achieve the effect of low raw material price, low adhesion characteristics, and reduced contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Prepare super-amphiphobic stainless steel wire mesh, the steps are:

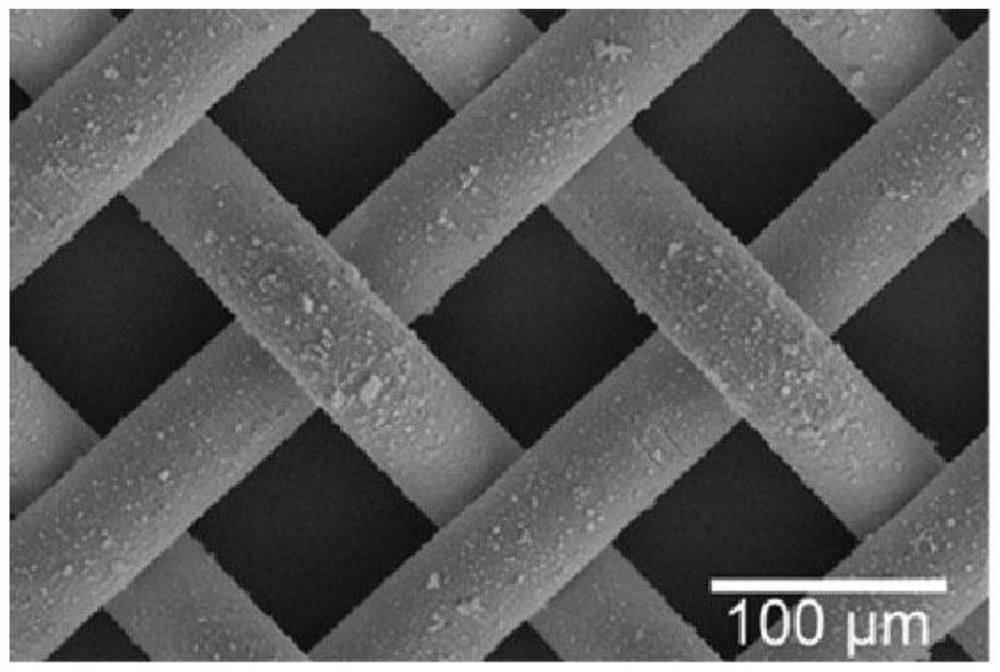

[0041] The first step: preparation of electrodeposited PEDOT template. The working electrode is stainless steel wire mesh (305 mesh, 3×6cm 2 ), first use deionized water, absolute ethanol and 1M NaOH solution to ultrasonically clean the stainless steel wire mesh, then activate it with 1M hydrochloric acid for 20min, then wash the stainless steel wire mesh with deionized water, dry it in the air, and electrodeposit the PEDOT film The amount is controlled at 150-210mC / cm 2 , as the first-level template for chemical vapor deposition in the next step.

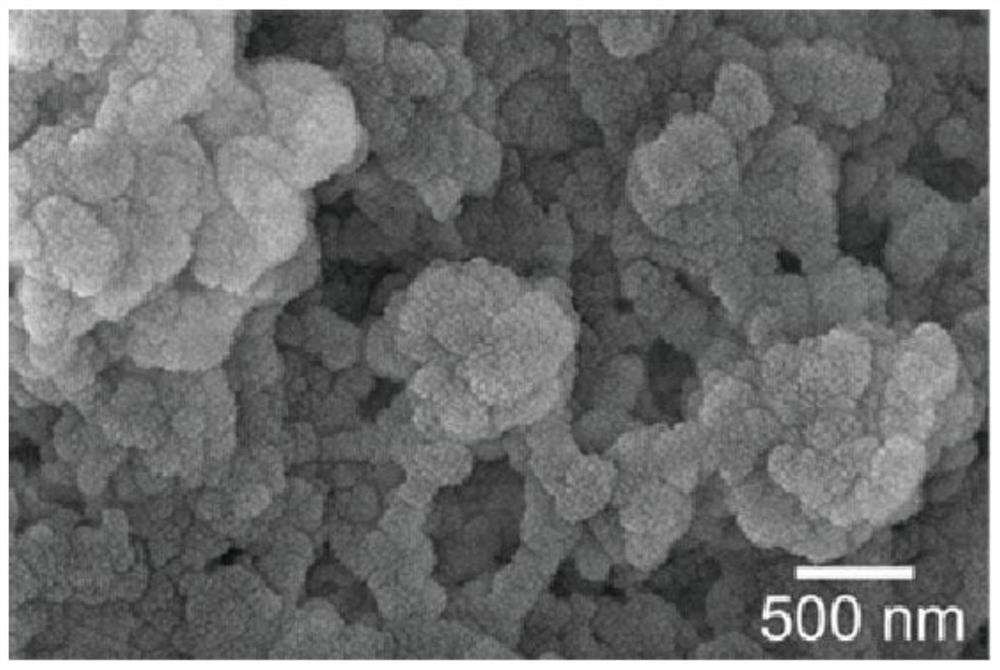

[0042] Step 2: Chemical vapor deposition of SiO on the first-level template 2 coating. The PEDOT film coating prepared around the stainless steel wire mesh was placed in a closed desiccator, and tetraethoxysilane TEOS was chemically vapor deposited at room temperature for 48 hours, and calcined in air at 500 ° C for 2 hours to remove the PEDOT template...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com