Preparation method of zinc cobaltate nanowire

A technology of zinc cobaltate and nanowires, which is applied in nanotechnology, chemical instruments and methods, cobalt compounds, etc., can solve problems such as high risk of experiments, great environmental hazards, and harmful water bodies, and achieve abundant raw material resources, low prices, Produce stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific technical solutions of the present invention are described in conjunction with the examples.

[0019] First, add 6mmol cobalt chloride hexahydrate, 3mmol zinc chloride and 3mol nitrogen triacetic acid into 35ml deionized water, stir magnetically until completely dissolved, then add 5ml isopropanol to form a mixed solution, transfer the mixed solution to 50ml polytetrafluoroethylene The hydrothermal reaction is carried out in a vinyl fluoride reactor, the reaction temperature is 180°C, and the reaction time is 6h. After the reaction is completed, it is cooled to room temperature. The zinc cobaltate precursor product is obtained by washing with water and ethanol and centrifuging, and then placed in a vacuum drying oven. dry. Finally, put the dried zinc cobaltate product in a muffle furnace and heat it up to 150°C at 3°C / min for two hours, then heat it up to 500°C at 10°C / min for one hour to obtain mesoporous cobaltate Zinc nanowires.

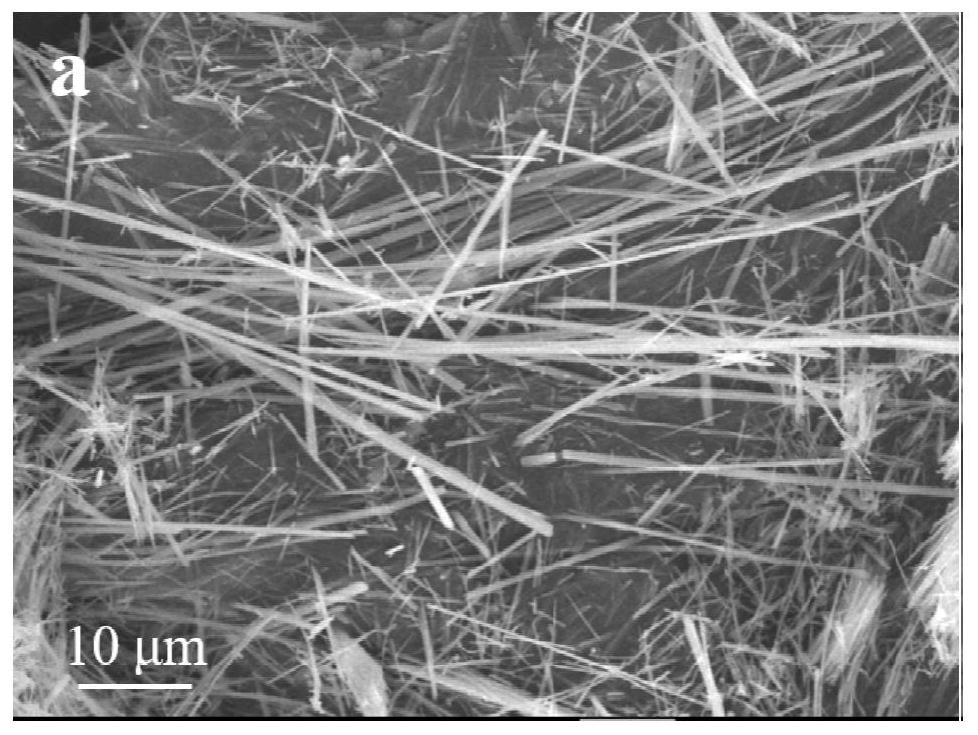

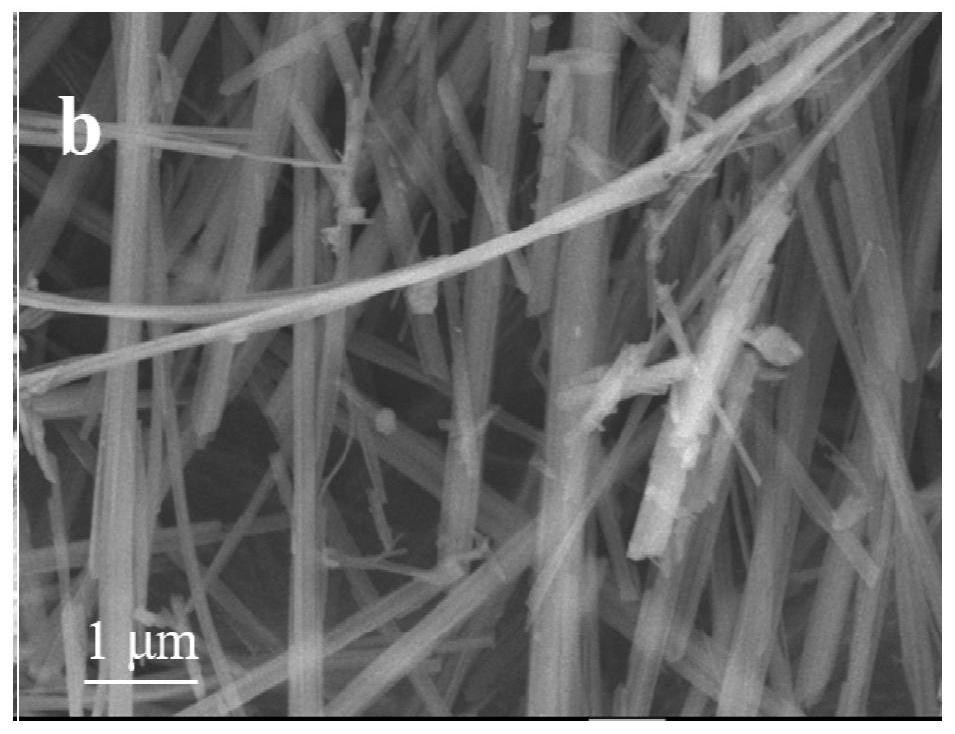

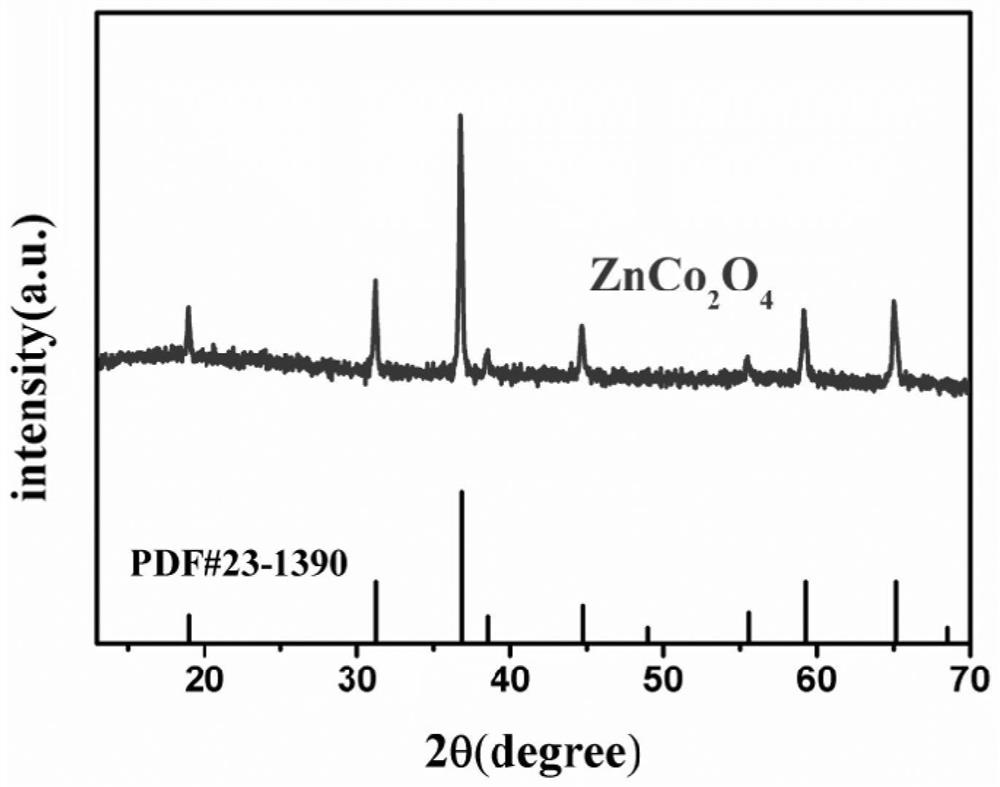

[0020] The scanning e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com