High-performance aluminum-based composite material and preparation method thereof

An aluminum-based composite material and high-performance technology, which is applied in the direction of improving energy efficiency and process efficiency, can solve the problems of weakening the enhancement effect of graphene, unfriendly environment, and increased energy consumption, so as to meet the needs of environmentally friendly production , low cost, and the effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

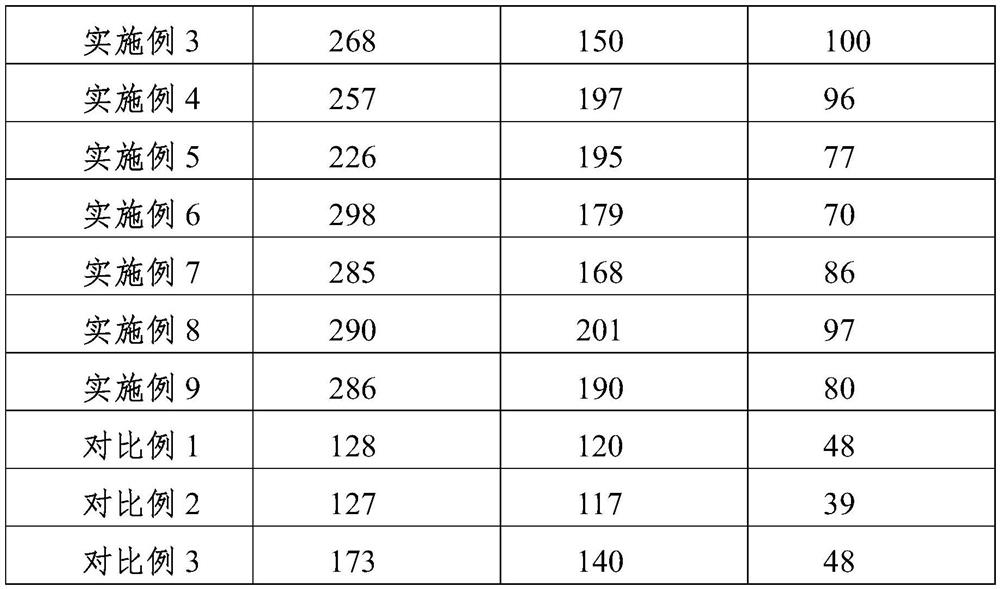

Examples

Embodiment 1

[0028] A high-performance aluminum-based composite material, comprising the following components by weight:

[0029] Aluminum alloy powder 100 parts

[0030] 80 parts graphite powder

[0031] 200 parts dry ice

[0032] Wherein, the aluminum alloy powder is an aluminum-manganese alloy; the graphite powder is selected from earthy graphite.

[0033] The preparation method of the above-mentioned high-performance aluminum-based composite material, the method comprising the following steps:

[0034] S1. Pretreating the aluminum alloy powder, specifically: adding the aluminum alloy powder into a cetyltrimethylammonium bromide solution with a mass fraction of 5%, stirring at room temperature for 3 hours, washing and drying, and drying The final aluminum alloy powder, graphite powder and dry ice are put into the ball mill jar, and after sealing, they are continuously ground and reacted for 100 hours at a speed of 5000rpm to obtain the alloy mixture; the aluminum alloy powder particl...

Embodiment 2

[0038] A high-performance aluminum-based composite material, comprising the following components by weight:

[0039] Aluminum alloy powder 90 parts

[0040] 70 parts of graphite powder

[0041] Dry ice 190 parts

[0042] Wherein, the aluminum alloy powder is aluminum-titanium alloy; the graphite powder is selected from natural flake graphite.

[0043] The preparation method of the above-mentioned high-performance aluminum-based composite material, the method comprising the following steps:

[0044] S1. Pretreating the aluminum alloy powder, specifically: adding the aluminum alloy powder into a cetyltrimethylammonium bromide solution with a mass fraction of 4%, stirring at room temperature for 2.7 hours, washing and drying, and The dried aluminum alloy powder, graphite powder and dry ice are put into a ball mill jar, sealed and ground continuously at a speed of 4500rpm for 90 hours to obtain an alloy mixture; the aluminum alloy powder has a particle size of 4500nm and a puri...

Embodiment 3

[0048] A high-performance aluminum-based composite material, comprising the following components by weight:

[0049] Aluminum alloy powder 80 parts

[0050] 60 parts graphite powder

[0051] Dry ice 180 parts

[0052] Wherein, the aluminum alloy powder is selected from aluminum-magnesium alloy, aluminum-silicon alloy; the graphite powder is selected from earthy graphite.

[0053] The preparation method of the above-mentioned high-performance aluminum-based composite material, the method comprising the following steps:

[0054] S1. Pretreating the aluminum alloy powder, specifically: adding the aluminum alloy powder into a cetyltrimethylammonium bromide solution with a mass fraction of 4%, stirring at room temperature for 2 hours, washing and drying, and drying The final aluminum alloy powder, graphite powder and dry ice are put into a ball mill jar, sealed and ground continuously at a speed of 4000rpm for 70 hours to obtain an alloy mixture; the particle size of the aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com