Hierarchical porous carbon cloth material, preparation method thereof and application of hierarchical porous carbon cloth material as supercapacitor electrode

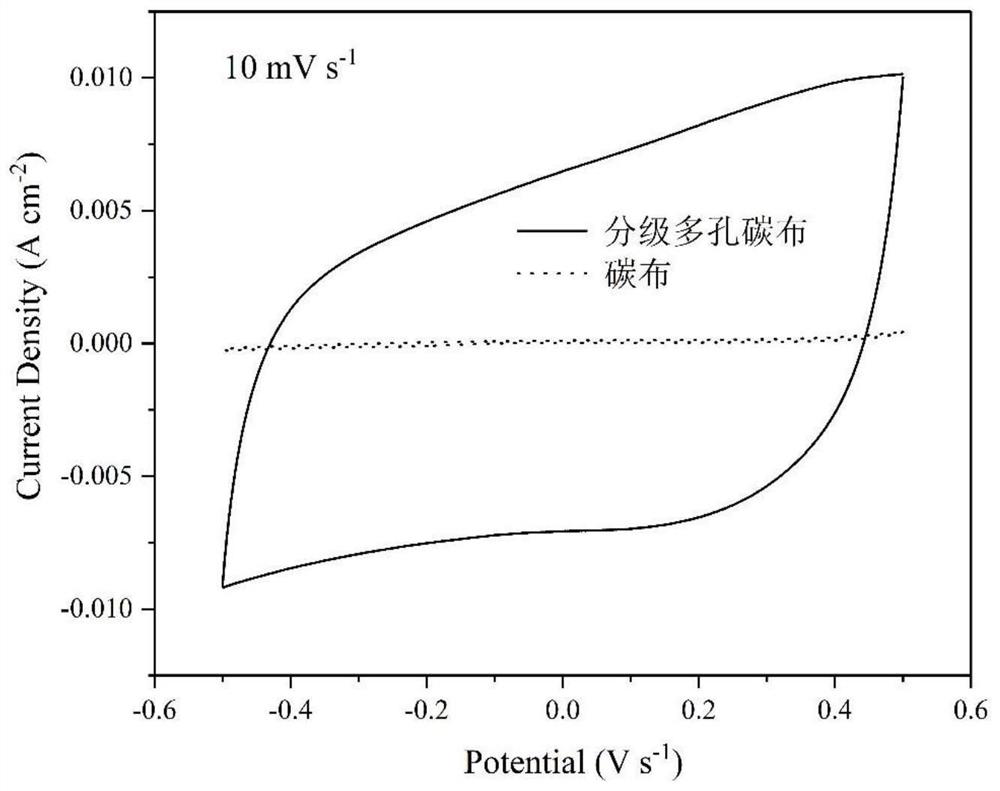

A hierarchically porous, hierarchically porous technology, applied in hybrid capacitor electrodes, nanotechnology for materials and surface science, hybrid/electric double-layer capacitor manufacturing, etc. The problems of low specific surface area of pure carbon materials can shorten the mass transfer distance, improve the utilization rate of energy storage, and increase the active surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation and Application of Example 1 Hierarchical Porous Carbon Cloth Material (1) The preparation method is as follows:

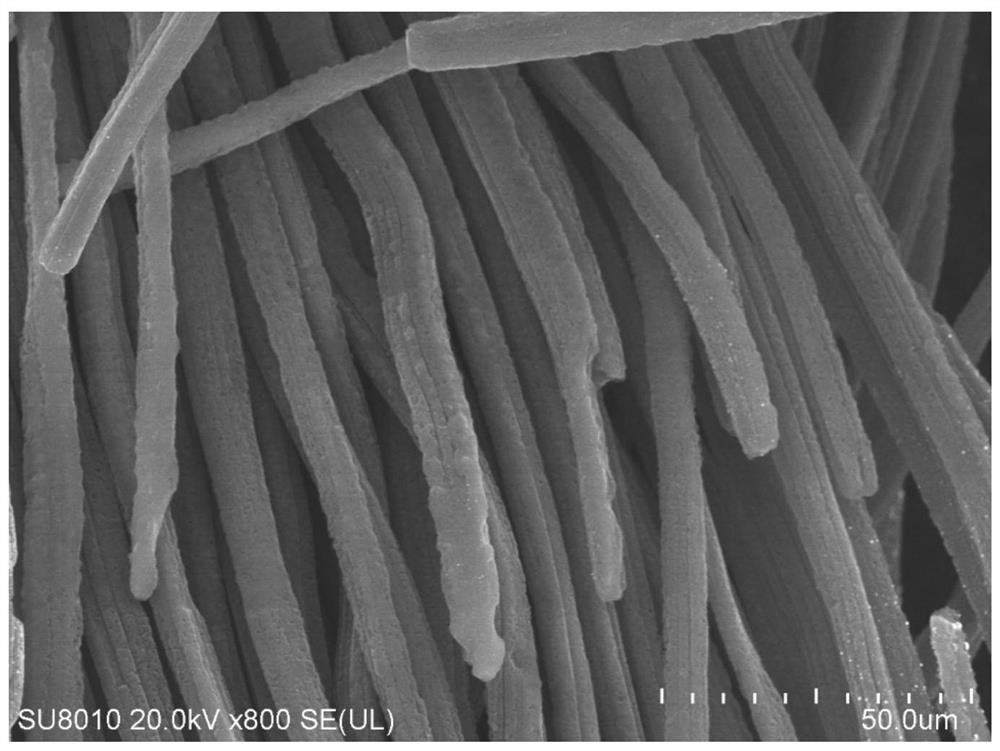

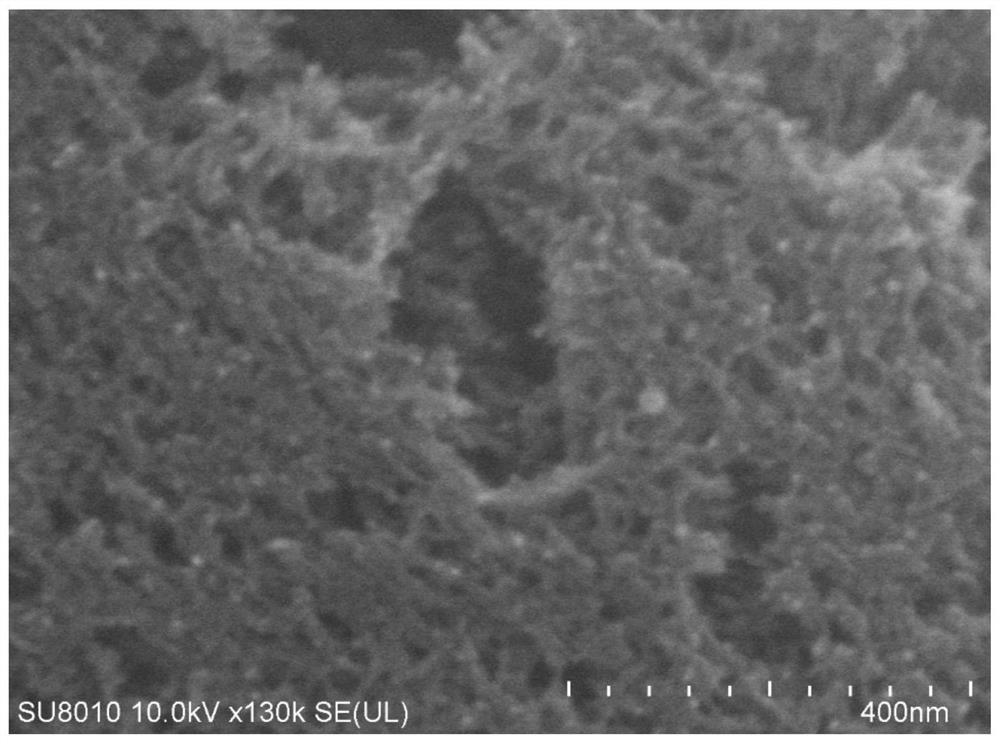

[0027] 1) Dissolve 5mmol of hexamethylenetetramine, 5mmol of zinc nitrate, and 2mL of ammonia water in 35mL of deionized water, and stir well to form a milky white suspension. After the above solution and size 3 x 3 cm 2 The carbon cloth (washed with ethanol and deionized water several times before use) was transferred to the reactor for hydrothermal reaction so that the surface of the carbon cloth was covered with a layer of ZnO nanorods. The reaction temperature was 95°C and the reaction time was 24h. The surface of the carbon cloth was rinsed with deionized water several times and dried at 60 °C.

[0028] 2) Transfer the carbon cloth wrapped with ZnO nanorods to a tube furnace with a heating rate of 5 °C / s, N 2 Annealing treatment under protection, firstly calcined at 600°C for 2h, then raised to 950°C for 2h, and then washed the annealed c...

Embodiment 2

[0033] Preparation and Application of Embodiment 2 Hierarchical Porous Carbon Cloth Material

[0034] (1) The preparation method is as follows:

[0035] 1) Dissolve 5mmol of hexamethylenetetramine, 5mmol of zinc nitrate, and 2mL of ammonia water in 35mL of deionized water, and stir well to form a milky white suspension. After the above solution and size 3 x 3 cm 2 The carbon cloth (washed with ethanol and deionized water several times before use) was transferred to the reactor for hydrothermal reaction so that the surface of the carbon cloth was covered with a layer of ZnO nanorods. The reaction temperature was 95 °C and the reaction time was 12 hours. The surface of the carbon cloth was rinsed with deionized water several times and dried at 60 °C.

[0036] 2) Transfer the carbon cloth wrapped with ZnO nanorods to a tube furnace with a heating rate of 5 °C / s, N 2 Annealing treatment under protection, firstly calcined at 600°C for 2h, then raised to 950°C for 2h, and then wa...

Embodiment 3

[0039] Preparation and Application of Example 3 Hierarchical Porous Carbon Cloth Material

[0040] (1) The preparation method is as follows:

[0041] 1) Dissolve 5mmol of hexamethylenetetramine, 5mmol of zinc nitrate, and 2mL of ammonia water in 35mL of deionized water, and stir well to form a milky white suspension. After the above solution and size 3 x 3 cm 2 The carbon cloth (washed with ethanol and deionized water several times before use) was transferred to the reactor for hydrothermal reaction so that the surface of the carbon cloth was covered with a layer of ZnO nanorods. The reaction temperature was 95°C and the reaction time was 24h. The surface of the carbon cloth was rinsed with deionized water several times and dried at 60 °C.

[0042] 2) Transfer the carbon cloth wrapped with ZnO nanorods to a tube furnace with a heating rate of 5 °C / s, N 2 Annealing treatment under protection, first calcined at 600 °C for 1 h, then raised to 950 °C for 2 h, and then washed th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com