Solid fuel cell and preparation method thereof

A fuel cell, solid-state technology, used in fuel cells, battery electrodes, circuits, etc., can solve the problems of cumbersome process, difficult to maintain the stability of anode structure, harsh reaction conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

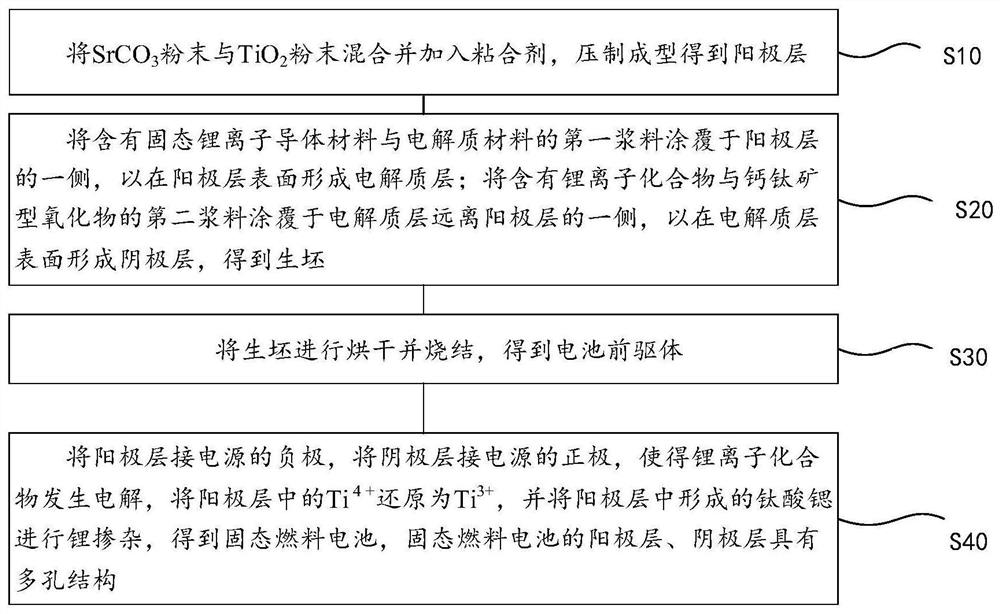

[0086] The present application also provides a preparation method of a solid fuel cell, such as image 3 shown, including the following steps:

[0087] S10, the SrCO 3 Powder and TiO 2 The powder is mixed and added with a binder, and pressed to form an anode layer, and the material of the anode layer includes strontium titanate;

[0088] S20, coating the first slurry containing solid lithium ion conductor material and electrolyte material on one side of the anode layer to form an electrolyte layer on the surface of the anode layer; Coating the second slurry of the substance on the side of the electrolyte layer away from the anode layer to form an electrolyte layer on the surface of the anode layer;

[0089] S30, drying and sintering the green body to obtain a battery precursor;

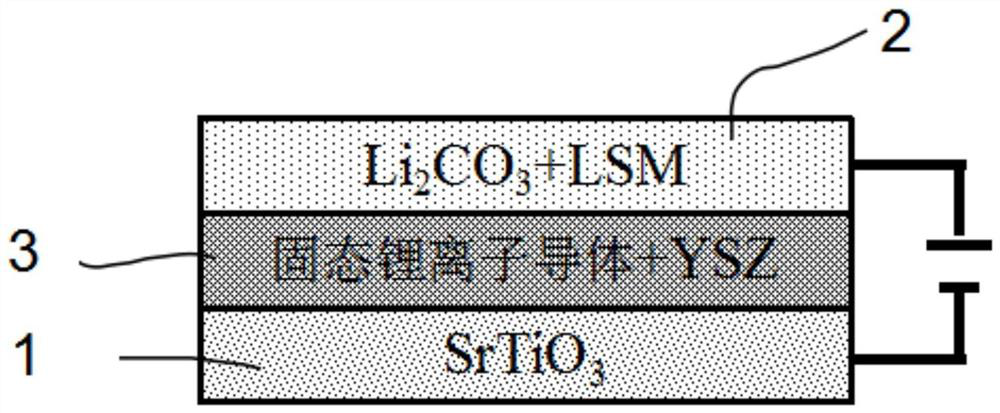

[0090] S40, connect the anode layer to the negative pole of the power supply, connect the cathode layer to the positive pole of the power supply, so that the lithium ion compound is electrolyzed, ...

Embodiment 1

[0136] (1) 147.62g of SrCO 3 powder with 79.9g of TiO 2 The powders were mixed, 45.504g of carbon powder was added as a pore-forming agent, and 1% polyvinyl alcohol (PVA) of the total mass of the above-mentioned powder was added, that is, 2.73g of PVA was used as a binder. After the powder is refined and mixed uniformly by ball milling, the powder is pressed into an anode layer by dry pressing. Among them, zirconia balls with a diameter of 3 mm are used for ball milling, and the ball milling speed is 300 r / min.

[0137] (2) Prepare the first slurry (electrolyte layer slurry)

[0138] First, sequentially weigh 13.3 g of Li 2 CO 3 , 70.2 g ZrO 2 , 103.5 g NH 4 h 2 PO 4 Powder, the powder is refined and mixed uniformly by ball milling, kept at 1000°C for 10 hours, and then cooled naturally to prepare LiZr 2 (PO 4 ) 3 Powder. Among them, zirconia balls with a diameter of 1 mm are used for ball milling, and the ball milling speed is 400 r / min.

[0139] Weigh 50g of com...

Embodiment 2

[0145] The only difference between this embodiment and embodiment 1 is that 8YSZ, Li 7 La 3 Zr 2 o 12 The first slurry (electrolyte layer slurry) was prepared with the same organic solvent.

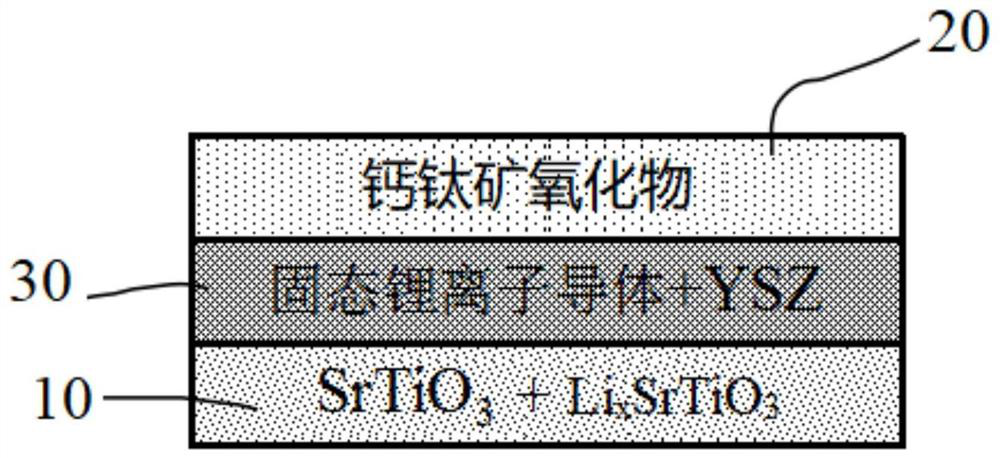

[0146] In the solid oxide fuel cell prepared above, the anode layer material includes strontium titanate and lithium-doped strontium titanate, the thickness is 10mm, and the porosity is 20%; the electrolyte layer includes 8YZ and Li 7 La 3 Zr 2 o 12 material, the cathode layer consists of La 0.5 Sr 0.5 MnO 3 Material. The thickness of the anode layer is 10mm, the porosity is 20%, the mass proportion of lithium-doped strontium titanate in the anode layer is 15%; the thickness of the electrolyte layer is 5 μm, dense and non-porous; The rate is 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com