Gluten-free bread and preparation method thereof

A gluten-free bread technology, which is applied in dough processing, baking, baked food, etc., can solve the problems of undense structure of bread core, lower consumer acceptability, and large proportion of starch, so as to achieve sensory and Good texture, good stabilization and emulsification, good emulsifying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

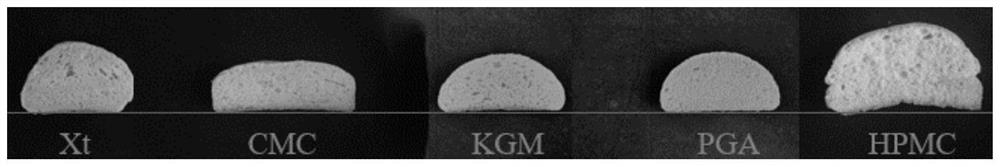

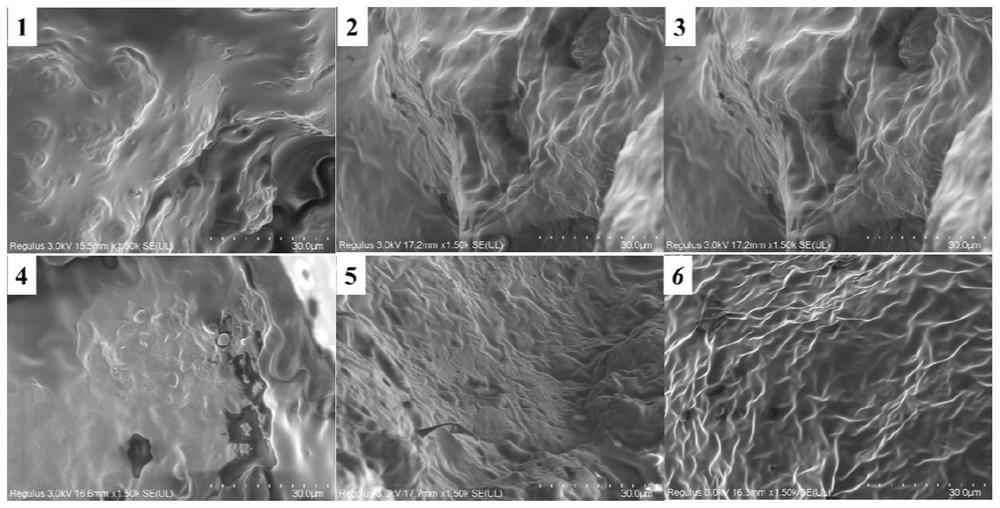

[0037] Embodiment 1: the selection of colloid

[0038] This example provides a formula for preparing gluten-free bread. In terms of mass percentage, the raw material powder ratio is as follows: rice flour, 100 parts, 1-3 parts of edible colloid, 2 parts of yeast, 5 parts of white sugar, edible 1 part of salt, 5 parts of corn oil, 90 parts of water.

[0039] Mix the above raw materials except corn oil and water evenly to make a mixed powder; add 90 parts of water to the mixed powder, stir at a low speed of 60r / min for 1min, stir at a medium speed of 90r / min for 2min, then add 5 parts After the corn oil was whipped at a high speed of 120r / min for 4 minutes, the dough was obtained;

[0040] The dough is divided and shaped into 90g of each quality, and packed into moulds;

[0041] Place the molded dough in a proofing box with a temperature of 38°C and a relative humidity of 90% to proof for 50 minutes, then put it into an oven with an upper and lower fire temperature of 170°C an...

Embodiment 2

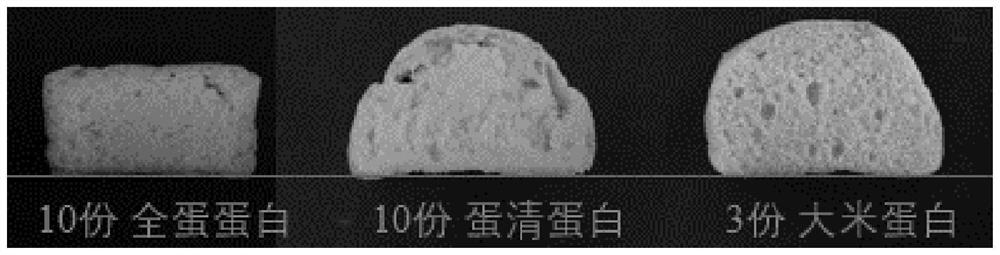

[0047] Embodiment 2: the selection of protein

[0048] This example provides a formula for preparing gluten-free bread. In terms of mass percentage, its raw material ratio is as follows: rice flour, 95 parts, protein 0-10 parts, hydroxypropyl methylcellulose 2 parts, alginic acid 0.2 parts of propylene glycol ester, 2 parts of yeast, 5 parts of white sugar, 1 part of edible salt, 5 parts of corn oil, and 95 parts of water.

[0049] Mix the above raw materials except corn oil and water evenly to make mixed powder;

[0050] Add 95 parts of water to the mixed powder, stir at a low speed of 60r / min for 1min, stir at a medium speed of 90r / min for 2min, then add 5 parts of corn oil and beat at a high speed of 120r / min for 4min to obtain a dough;

[0051] The dough is divided and shaped into 90g of each quality, and packed into moulds;

[0052] Place the molded dough in a proofing box with a temperature of 38°C and a relative humidity of 90% to proof for 50 minutes, then put it int...

Embodiment 3

[0060] Embodiment 3: Determination of the amount of water added

[0061] This example provides a formula for preparing gluten-free bread. In terms of mass percentage, the raw material powder ratio is as follows: rice flour, 95 parts, rice protein 3 parts, hydroxypropyl methylcellulose 2 parts, yeast 2 parts 5 parts of white granulated sugar, 1 part of edible salt, 5 parts of corn oil, and 75-100 parts of water.

[0062] Mix the above-mentioned raw material powders except corn oil and water evenly to make mixed powder;

[0063] Add a certain amount of water to the mixed powder, stir at a low speed of 60r / min for 1min, stir at a medium speed of 90r / min for 2min, then add 5 parts of corn oil and whip at a high speed of 120r / min for 4min to obtain a dough;

[0064] The dough is divided and shaped into 90g of each quality, and packed into moulds;

[0065] Place the molded dough in a proofing box with a temperature of 38°C and a relative humidity of 90% for 50 minutes, then put it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com