Method for producing hydrogen by recycling waste lithium ion battery positive electrode material in combination with electrochemistry

A technology for lithium ion batteries and positive electrode materials, which is applied in the field of recycling waste lithium ion battery positive electrode materials combined with electrochemical hydrogen production, can solve the problems that the electrochemical performance of new positive electrode materials is difficult to achieve the expected target and the processing cost is high, and achieves alleviation of battery solid waste. The effect of difficult environmental pressure, low treatment cost, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, the method for recycling waste lithium-ion battery cathode materials combined with electrochemical hydrogen production includes the following steps:

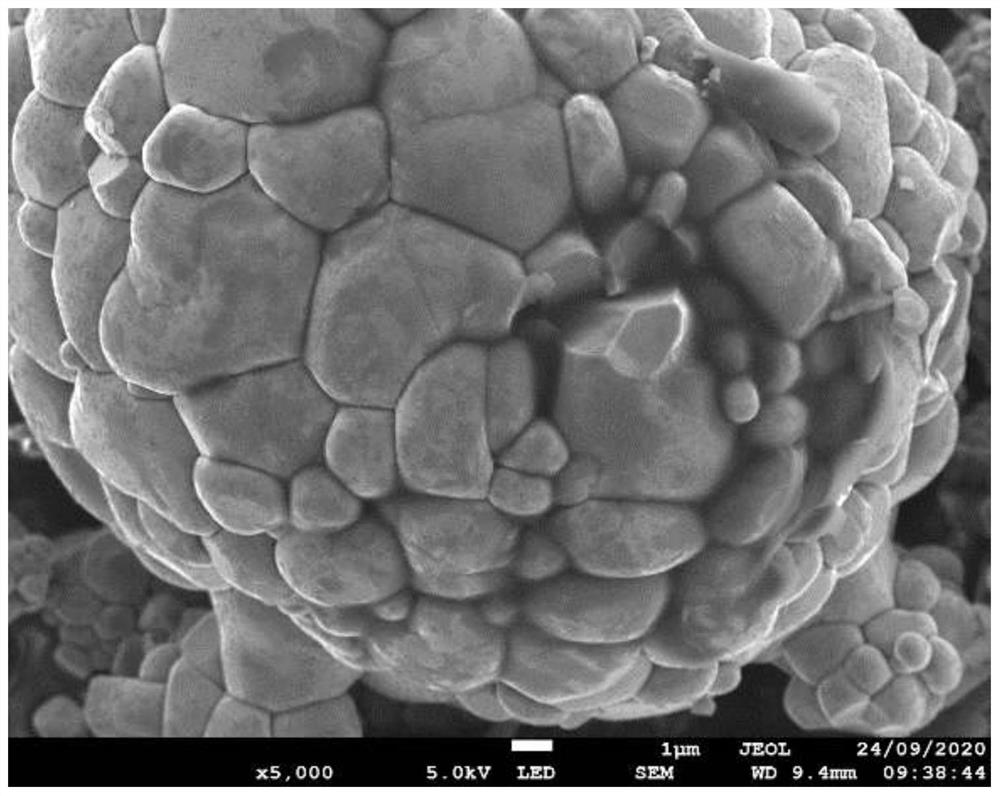

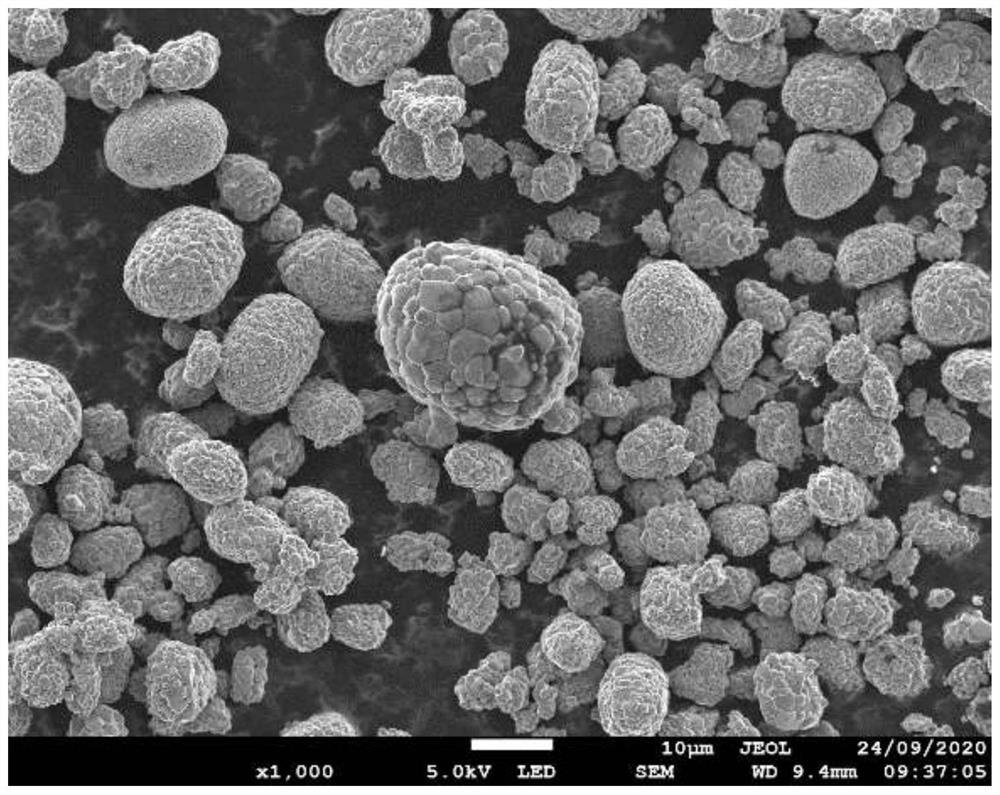

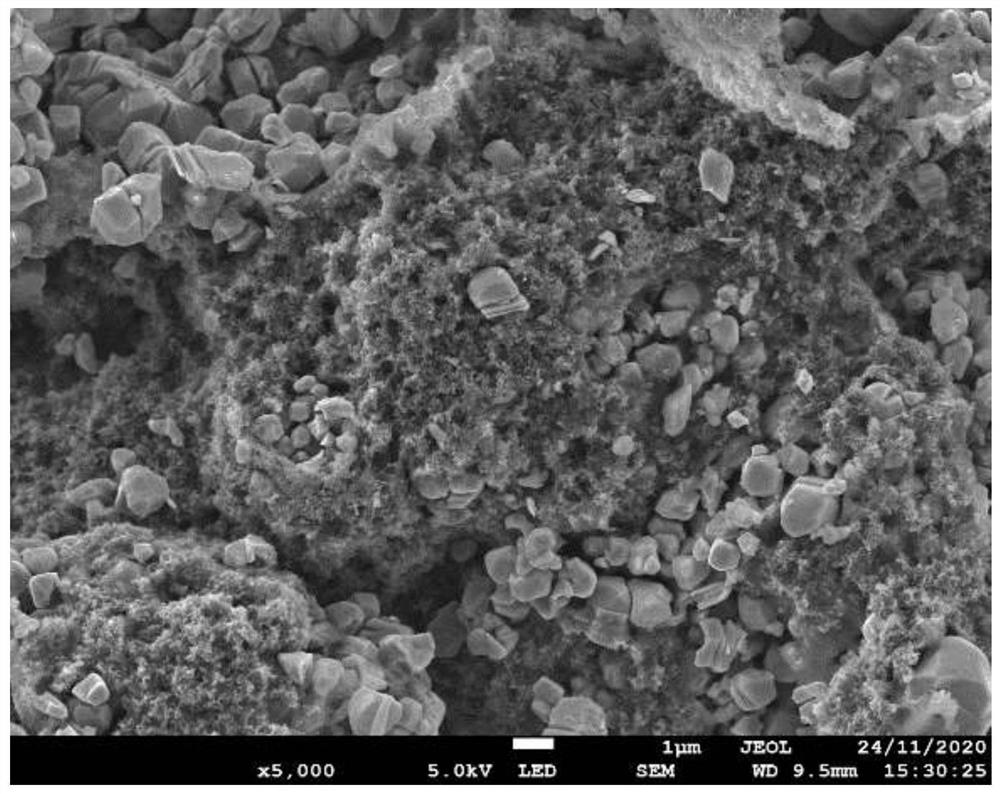

[0040] (1) Recycling waste LiNi 0.8 co 0.1 mn 0.1 o 2 The material is ball milled, passed through a 100-mesh sieve, and dried to obtain the reclaimed powder of the secondary agglomerated particles of the waste positive electrode material. The appearance of the reclaimed powder is as follows: figure 1 and figure 2 shown;

[0041] (2) Mix the recovered powder of secondary agglomerated particles of waste cathode materials obtained in step (1) with acetylene black and PVDF at a mass ratio of 80:10:10, disperse them in N-methylpyrrolidone solution, stir evenly, and carry out Dry to get pole pieces;

[0042] (3) With the pole piece obtained in step (2) as the positive electrode and the graphite electrode as the negative electrode, the 2 SO 4In the solution, first charge at a constant current of 0.02...

Embodiment 2

[0049] In this embodiment, the method for recycling waste lithium-ion battery cathode materials combined with electrochemical hydrogen production includes the following steps:

[0050] (1) Recycling waste LiNi 0.8 co 0.1 mn 0.1 o 2 The material is ball milled, passed through a 200-mesh sieve, and dried to obtain the recycled powder of the secondary agglomerated particles of the waste cathode material;

[0051] (2) Mix the recovered powder of secondary agglomerated particles of waste cathode materials obtained in step (1) with acetylene black and PVDF at a mass ratio of 80:10:10, disperse them in N-methylpyrrolidone solution, stir evenly, and carry out Dry to get pole pieces;

[0052] (3) With the pole piece obtained in step (2) as the positive electrode and the graphite electrode as the negative electrode, the 2 SO 4 In the solution, first charge at a constant current of 0.02 A to 2.0 V, and then charge at a constant voltage at 2.0 V to a current of 0.1 mA. The secondary...

Embodiment 3

[0057] In this embodiment, the method for recycling waste lithium-ion battery cathode materials combined with electrochemical hydrogen production includes the following steps:

[0058] (1) Recycling waste LiNi 0.8 co 0.15 al 0.05 o 2 The material is ball milled, passed through a 150-mesh sieve, and dried to obtain the recycled powder of the secondary agglomerated particles of the waste cathode material;

[0059] (2) Mix the recovered powder of secondary agglomerated particles of waste cathode materials obtained in step (1) with acetylene black and PVDF at a mass ratio of 80:10:10, disperse them in N-methylpyrrolidone solution, stir evenly, and carry out Dry to get pole pieces;

[0060] (3) With the pole piece obtained in step (2) as the positive electrode and the graphite electrode as the negative electrode, the 2 SO 4 In the solution, first charge at a constant current of 0.03 A to 2.0 V, and then charge at a constant voltage at 2.0 V to a current of 0.1 mA. The seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com