Functionalized graphene-carbon black composite granules as well as preparation method and application thereof

A technology of fossil and graphene, applied in the field of graphene-carbon black composite pellet preparation, can solve the problems of low chemical stability, poor compatibility, direct application limitation, etc., achieve good compatibility, high uniformity, reduce The effect of repulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The specific preparation process of the functionalized graphene / carbon black composite pellets involved in the present embodiment is as follows:

[0027]

[0028] The specific implementation includes the following steps: use water as a solvent, add tannic acid with a mass fraction of 0.5wt%, and after dissolving, add graphene with a mass fraction of 10wt%, in an ultrasonic wave with a power of 40w, ultrasonicate in a water bath at 25°C for 10min , put graphene in 0.5-10L deionized water to form a graphene solution with a concentration of 0.5-2mg / ml, then ultrasonically treat the graphene solution for 10min-100min, add the carbon black granulation water directly, and then add the binder ( Such as plant polyphenols), the amount of the binder accounts for 3% to 6% of the granulation water, and the composite pellets are obtained through a carbon black granulator after the stirring teeth with a rotation speed controlled at 300 to 600r / min are strongly stirred and mixed, an...

Embodiment 2

[0030] Embodiment 2: take by weighing the functionalized graphene-carbon black composite pellet of 10g (functionalized graphene: carbon black composite ratio is 1:100) prepared according to the method of embodiment 1 and 50g natural rubber in internal mixer Refined for 10 minutes, and the upper and lower tablets were refined in Kailian.

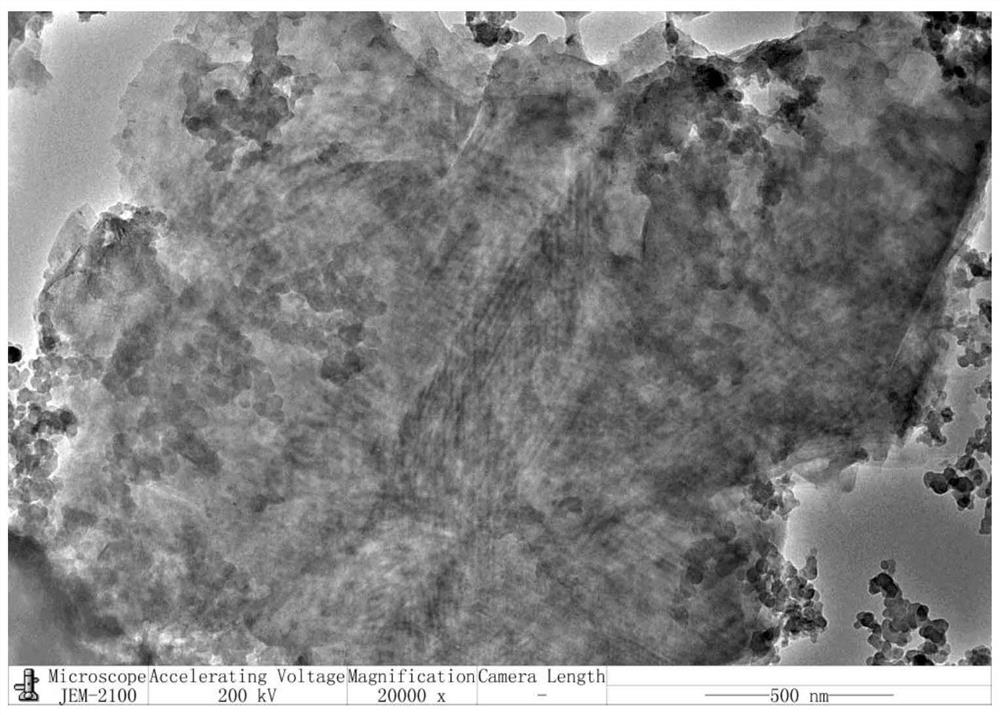

[0031] like figure 1 For the TEM figure of the functionalized graphene / carbon black composite material prepared in embodiment 1, the composite interaction of functionalized graphene and carbon black suppresses the strong interaction between graphene sheets, so graphene has no agglomeration, and carbon black The black is evenly compounded and distributed on the graphene sheet.

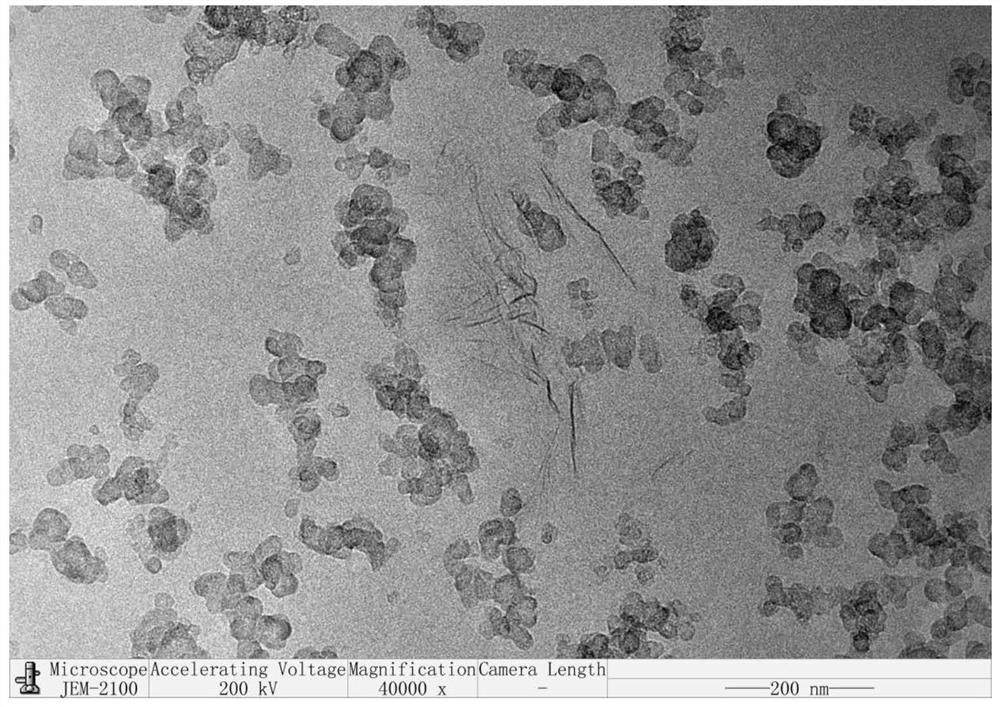

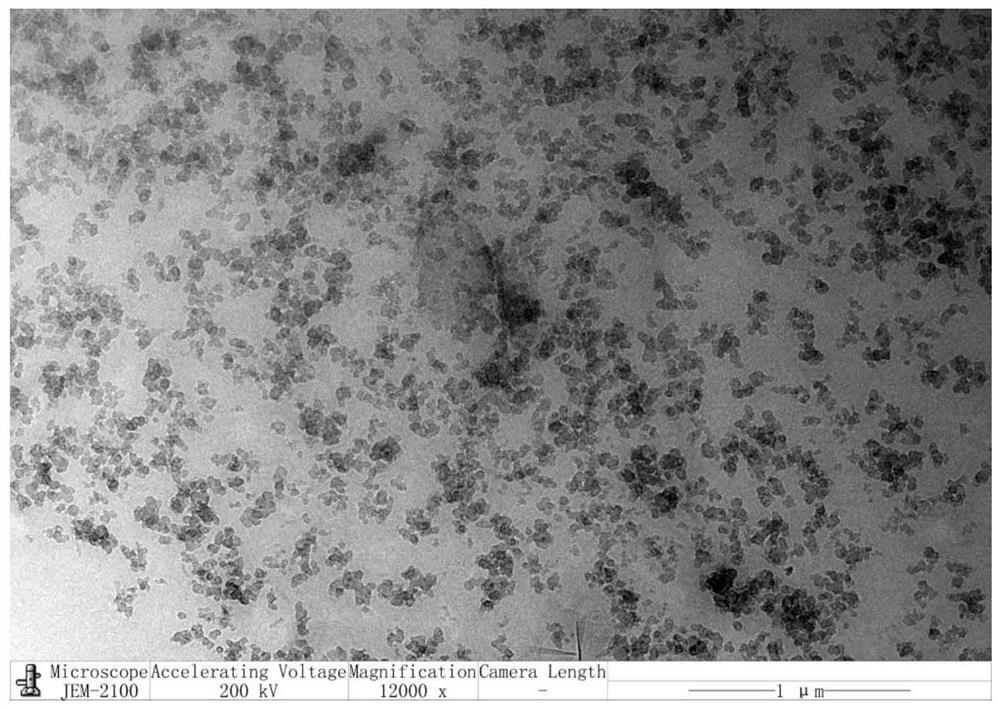

[0032] like Figure 2-3 Shown, the functionalized graphene / carbon black composite granular material prepared by the present invention ( image 3 ) is stably and uniformly dispersed in natural rubber, graphene has no agglomeration, graphene flakes can still be observ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com