Anti-sticking coating for sintering of hard alloy as well as preparation method and application thereof

A technology of anti-sticking coatings and hard alloys, applied in the direction of fireproof coatings, coatings, etc., can solve the problems of easy contact with graphite plates, high processing costs, alloy carburization, etc., to achieve stability, good stability, increase The effect of high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A cemented carbide sintering anti-stick coating according to an embodiment of the present invention, the anti-stick coating is formed by mixing solid spacer powder and liquid binder. Among them, the solid isolation powder is composed of the following materials:

[0042]

[0043] The liquid adhesive consists of the following materials:

[0044]

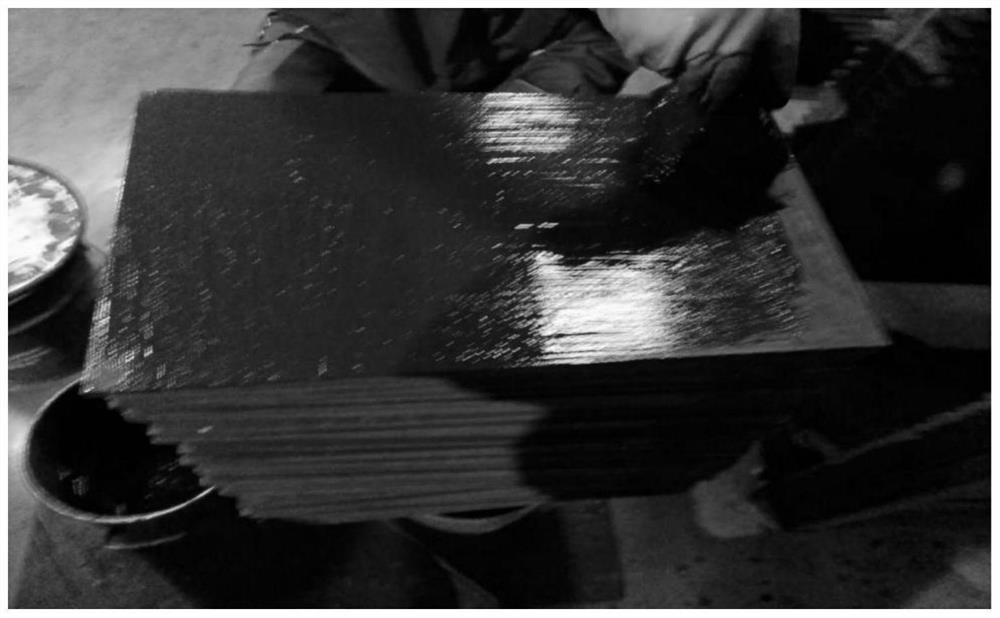

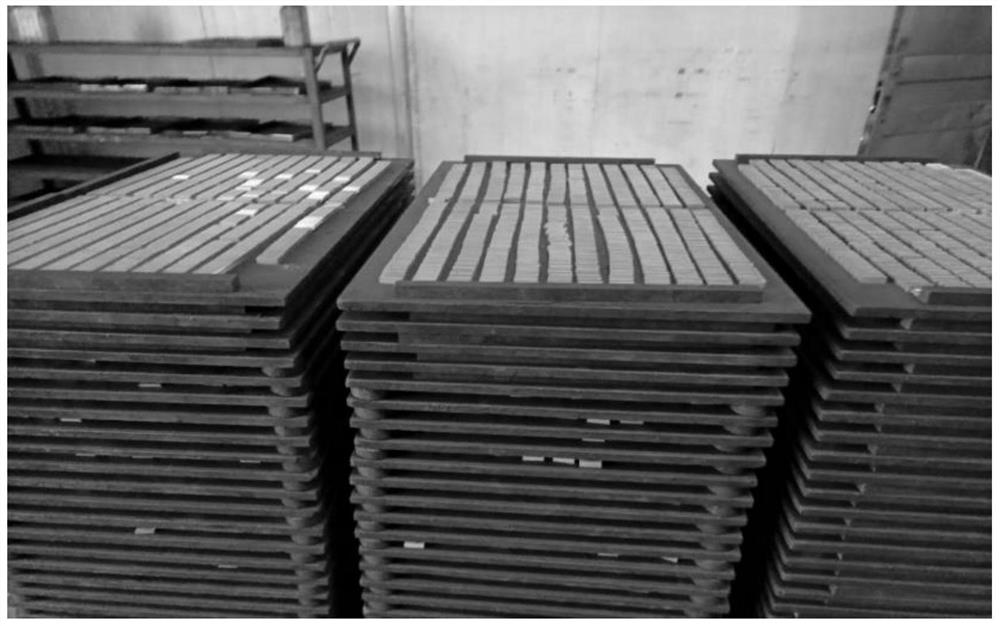

[0045] The preparation method of this cemented carbide sintering anti-stick coating is as follows:

[0046] Mix the materials in the above solid isolation powder in proportion to obtain a solid isolation powder, put the solid isolation powder into the ball mill barrel; put cemented carbide grinding balls into the ball mill barrel, the mass ratio of the ball to material is 3:1;

[0047] First, add water-soluble modified phenolic resin liquid, hydroxypropyl methylcellulose powder, Tween-80 liquid, flake PEG, granular urotropine and polydimethylsiloxane liquid into the container in proportion; Then put the diluent ethanol ...

Embodiment 2

[0050] A cemented carbide sintered anti-sticking coating according to an embodiment of the present invention, the anti-sticking coating includes a solid spacer powder and a liquid binder, wherein the solid spacer powder is composed of the following materials:

[0051]

[0052] The liquid adhesive consists of the following materials:

[0053]

[0054] The preparation method of this cemented carbide sintering anti-stick coating is as follows:

[0055] Mix the materials in the above solid isolation powder in proportion to obtain a solid isolation powder, put the solid isolation powder into the ball mill barrel; put cemented carbide grinding balls into the ball mill barrel, the mass ratio of the ball to material is 3:1;

[0056] First, add water-soluble modified phenolic resin liquid, hydroxypropyl methylcellulose powder, Tween-80 liquid, flake PEG, granular urotropine and polydimethylsiloxane liquid into the container in proportion; Then put the diluent ethanol and deioni...

Embodiment 3

[0059] A cemented carbide sintered anti-sticking coating according to an embodiment of the present invention, the anti-sticking coating includes a solid spacer powder and a liquid binder, wherein the solid spacer powder is composed of the following materials:

[0060]

[0061] The liquid adhesive consists of the following materials:

[0062]

[0063] The preparation method of this cemented carbide sintering anti-stick coating is as follows:

[0064] Mix the materials in the above solid isolation powder in proportion to obtain a solid isolation powder, put the solid isolation powder into the ball mill barrel; put cemented carbide grinding balls into the ball mill barrel, the mass ratio of the ball to material is 3:1;

[0065] First, add water-soluble modified phenolic resin liquid, hydroxypropyl methylcellulose powder, Tween 80 liquid, flake PEG, granular urotropine and polydimethylsiloxane liquid into the container in proportion; then Put the diluent ethanol and deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com