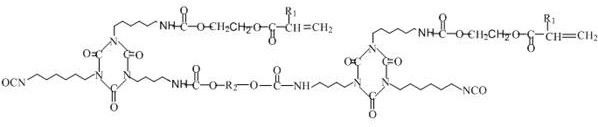

UV-LED and moisture dual-curable environment-friendly three-proofing adhesive and preparation method thereof

A UV-LED, dual-curing technology, applied in the direction of adhesives, adhesive additives, adhesive types, etc., can solve the problems of UV-LED surface stickiness, less free radical active groups, easy to stick to dust, etc. The surface is dry and smooth, the surface is dry and not sticky, and the effect of improving the cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

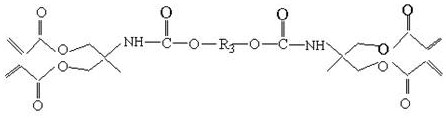

Method used

Image

Examples

Embodiment 1

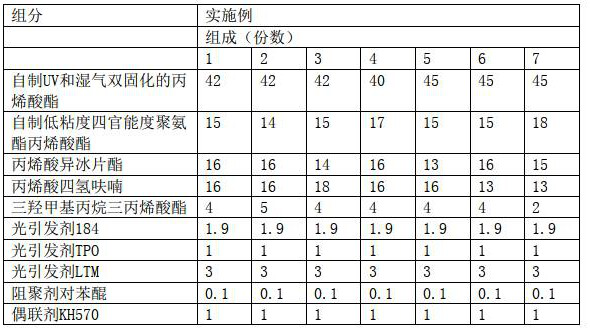

[0047] Accurately weigh various raw materials according to the number of parts in the formula in Table 1. According to the parts by weight, 42 parts of self-made UV and moisture dual-curing acrylate, 15 parts of self-made low-viscosity bifunctional acrylate, and 15 parts of acrylic isoborneol Esters, 16 parts of tetrahydrofuran acrylate, 4 parts of trimethylolpropane triacrylate, 1.9 parts of photoinitiator 184, 1 part of photoinitiator TPO, 3 parts of photoinitiator LTM, 0.1 part of polymerization inhibitor p-benzoquinone, 1 part The coupling agent KH570 is added into the mixer in turn, the temperature is controlled at 20-30°C, the vacuum condition is -0.1--0.08MPa, and it is stirred at 800 rpm for 1 hour until it is evenly stirred, and the nitrogen pressure is released;

[0048] Put the photoinitiator into the mixer after depressurization, avoid light, control the temperature at 20-30°C, and the vacuum condition is -0.1-0.08MPa, stir at 800 rpm for 1 hour until the stirring i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com