Intelligent control strengthening system and process for direct coal liquefaction

A technology of direct coal liquefaction and intelligent control, applied in the field of coal-to-liquids, can solve the problems of low reaction efficiency of direct coal liquefaction, and achieve the effects of reducing reaction pressure, increasing product yield and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

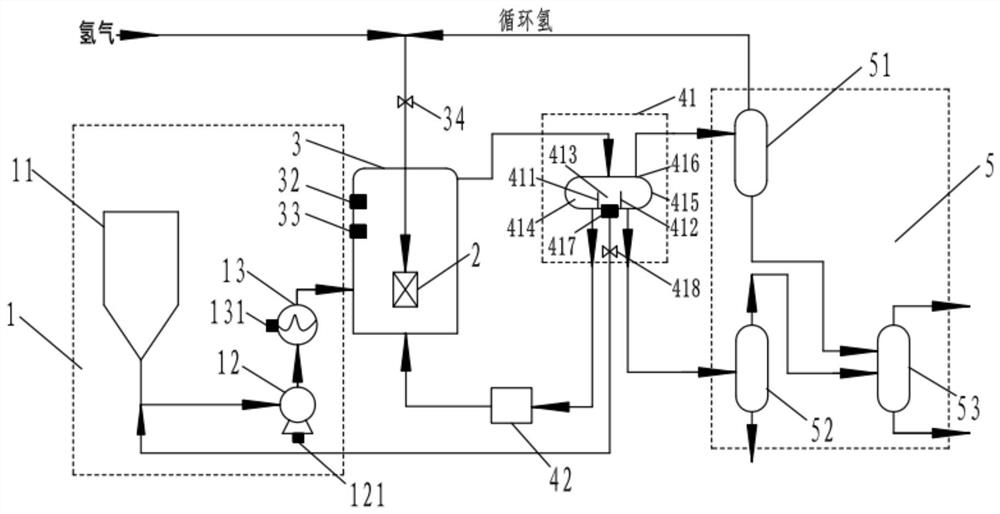

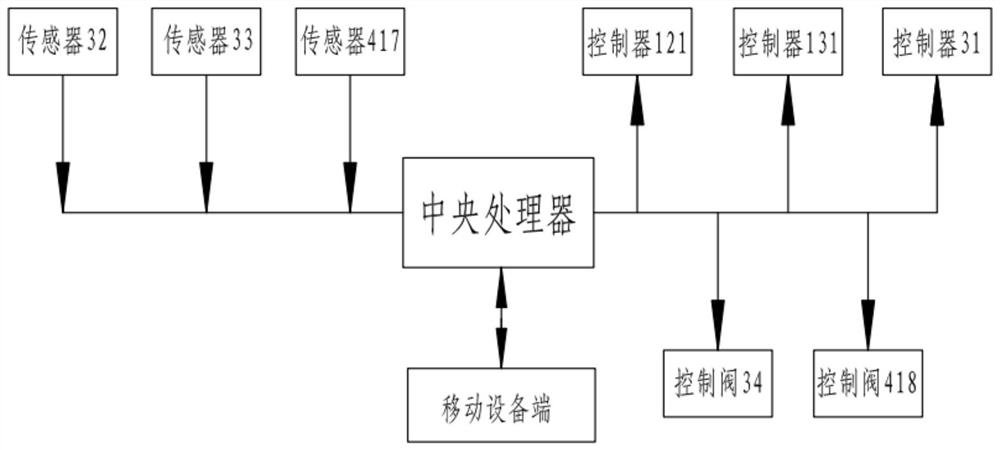

Method used

Image

Examples

Embodiment 1

[0076] The reaction temperature during the hydrogenation liquefaction treatment of the reactor is 400°C, the pressure is 2-14MPa, preferably 3-8MPa, and the liquid hourly space velocity is 0.7-1.2h -1, The volume ratio of hydrogen to oil is 100-700; the material flow rate returned by the circulation unit to the reactor shell is 2-5 times that of the direct coal liquefied oil feed flow rate, and the filling volume of the catalyst is 30% of the effective volume of the ebullated bed reactor 25-65%. In addition, the range of preset operating conditions can be flexibly adjusted according to different raw material compositions, different product requirements or different catalysts, which further ensures that the reaction is fully and effectively carried out, thereby ensuring the reaction rate and achieving the purpose of strengthening the reaction .

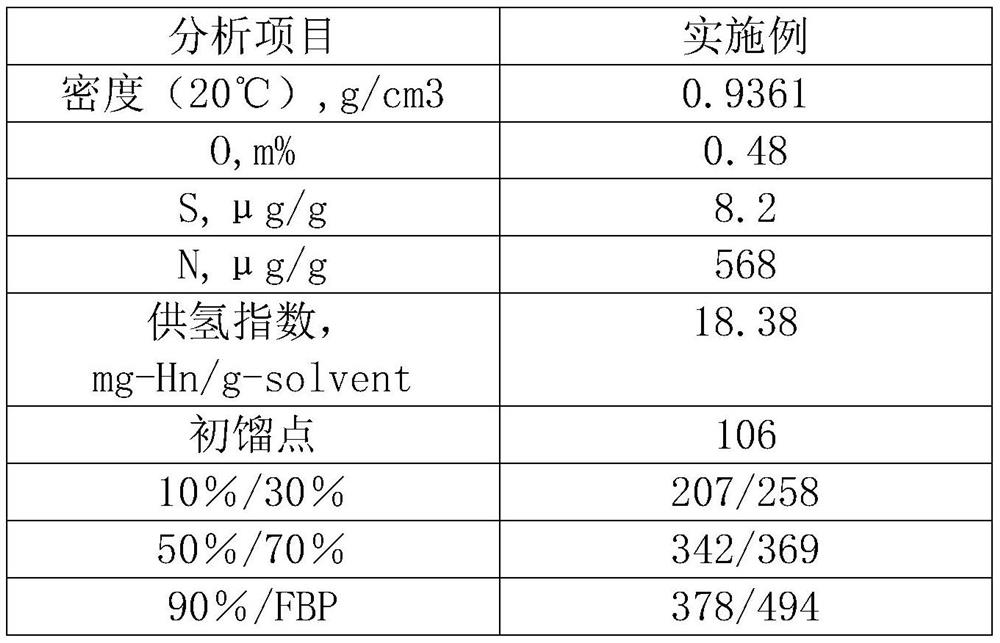

[0077] The reaction effect is shown in Table 1:

[0078] Table 1

[0079]

Embodiment 2

[0081] The reaction temperature during the hydrogenation liquefaction treatment of the reactor is 420°C, the pressure is 2-14MPa, preferably 2-6MPa, and the liquid hourly space velocity is 0.7-1.2h -1, The volume ratio of hydrogen to oil is 100-700; the material flow rate returned by the circulation unit to the reactor shell is 2-5 times that of the direct coal liquefied oil feed flow rate, and the filling volume of the catalyst is 30% of the effective volume of the ebullated bed reactor 25-65%. In addition, the range of preset operating conditions can be flexibly adjusted according to different raw material compositions, different product requirements or different catalysts, which further ensures that the reaction is fully and effectively carried out, thereby ensuring the reaction rate and achieving the purpose of strengthening the reaction .

[0082] The reaction effect is shown in Table 2:

[0083]Table 2

[0084]

Embodiment 3

[0086] The reaction temperature during the hydrogenation liquefaction treatment of the reactor is 450°C, the pressure is 2-14MPa, preferably 2-8MPa, and the liquid hourly space velocity is 0.7-1.2h -1, The volume ratio of hydrogen to oil is 100-700; the material flow rate returned by the circulation unit to the reactor shell is 2-5 times that of the direct coal liquefied oil feed flow rate, and the filling volume of the catalyst is 100% of the effective volume of the ebullated bed reactor 25-65%. In addition, the range of preset operating conditions can be flexibly adjusted according to different raw material compositions, different product requirements or different catalysts, which further ensures that the reaction is fully and effectively carried out, thereby ensuring the reaction rate and achieving the purpose of strengthening the reaction .

[0087] The reaction effect is shown in Table 3:

[0088] table 3

[0089]

[0090]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com