Improved culture medium for in-vitro amplification culture of cultured meat seed cells and application thereof

A technology for expanding culture and seeding cells, applied in the field of stem cells and animal cell culture meat, it can solve the problems of inability to meet the quantity and functional requirements, low production capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

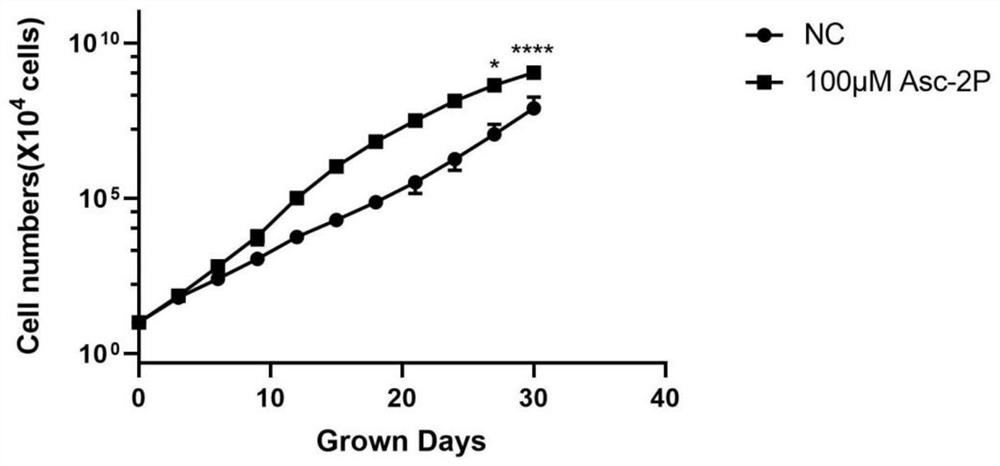

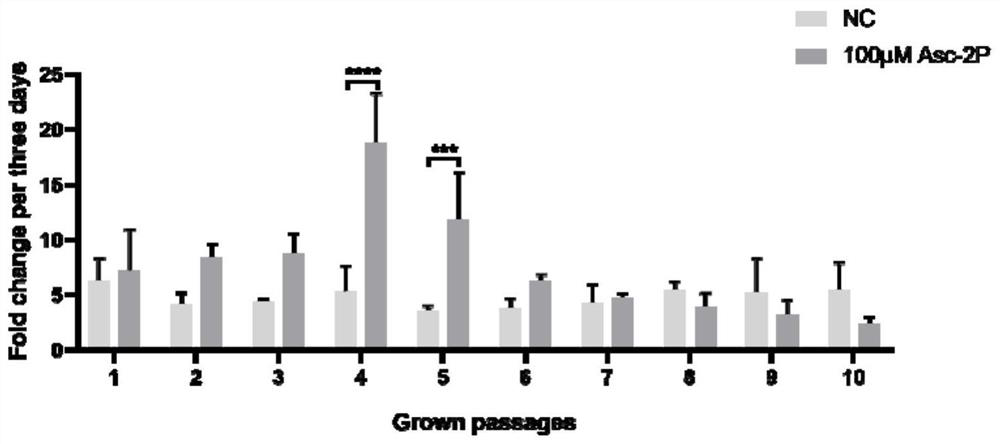

[0070] Example 1 Separation and sorting of porcine muscle stem cells and research on the proliferation rate of long-term culture in vitro:

[0071] 1) Isolation of single cells: Soak freshly slaughtered piglets in 75% ethanol for one minute, cut the skin and fascia from the front and rear legs under aseptic conditions, and take the whole muscle tissue and store it in basal culture medium. Under aseptic conditions, rinse the muscle tissue in DMEM for 2-3min, move to another clean petri dish containing DMEM, cut it into centrifuge tubes containing DMEM with a sterile scalpel, press 1: Add collagenase D and dissipative enzyme II solutions to the total system ratio of 6, mix well and repeatedly suck muscle tissue, incubate in a 37 ° incubator, and repeat pumping every 15 minutes until the solution can pass through 10ml pipette Take a 30ml syringe with a needle, add 5ml of basal medium and an appropriate amount of PBS dilution solution. Filter the solution with a 100μm cell strain...

Embodiment 2

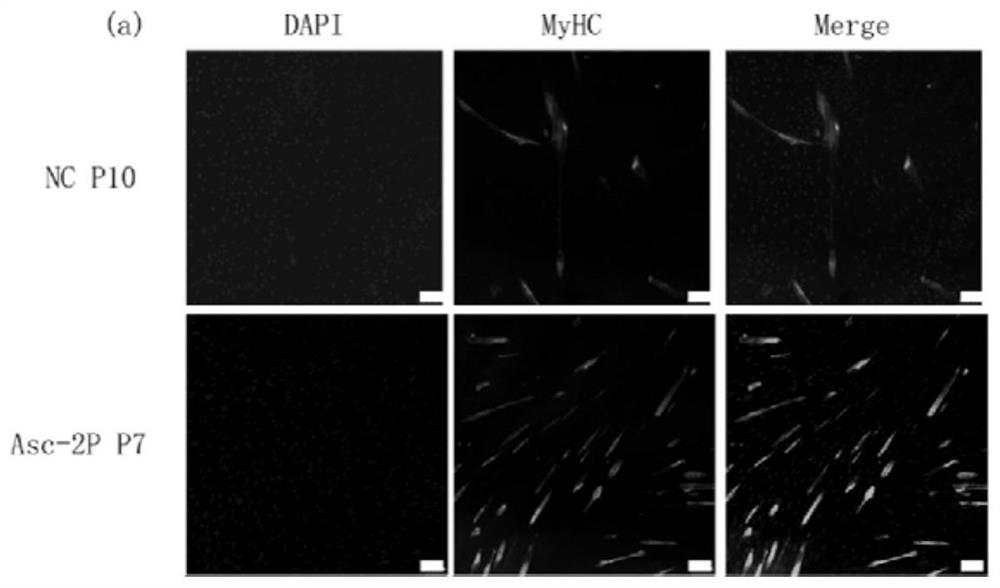

[0081] Example 2 Detection of Muscle Stem Cell Differentiation Level

[0082] 1) Induced differentiation of muscle stem cells: Take two groups of porcine muscle stem cells in Example 1 and move them into a differentiation culture dish, continue culturing until the cell confluence reaches more than 90%, and then replace it with a differentiation medium for culture. The differentiation culture dish is pre-coated with 10- 200 μg / ml Matrigel 3.5cm culture dish, the differentiation medium is 2vol% horse serum, 97vol% DMEM medium, 1vol% penicillin-streptomycin double antibody, in the penicillin-streptomycin double antibody solution, penicillin The content of streptomycin is 10mg / ml and the content of streptomycin is 10000U / ml. Perform a half-change of medium every two days, that is, suck off half of the differentiation medium, add half of the new differentiation medium, and differentiate for 3-6 days.

[0083] 2) Detection of differentiation marker MyHC: Take the cultured cells, wa...

Embodiment 3

[0086] Example 3 Preparation of cultured meat products and detection of differentiation level

[0087] This experiment was divided into conventional growth medium culture group (NC) and modified medium culture group added with Asc-2P (Asc-2P).

[0088] 1) Preparation of cultured meat products: Take type I collagen (3.35-3.73mg / ml concentration), mix with DMEM medium containing phenol red, 1M NaOH and Matrigel (manufacturer CORNING, batch number 356234) to make a mixed solution. The volume ratio of type I collagen, DMEM medium containing phenol red, NaOH solution, and Matrigel is 50:40:1.5:8, and the sodium hydroxide solution adjusts the pH value of the mixed solution to 7.3-7.5. In this embodiment, collagen , DMEM medium containing phenol red, NaOH solution, and Matrigel were added in 500 ul, 400 ul, 15 ul, and 8 ul respectively to obtain a mixed solution.

[0089] The young pig muscle adherent stem cells were divided into two groups, inoculated into different cell culture di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com