Polypropylene microporous membrane as well as preparation method and application thereof

A technology of polypropylene microporous membrane and polypropylene, which is applied in the direction of electrical components, electrochemical generators, circuits, etc., can solve the problem of high drafting conditions, reduced controllability of dry membrane production process, and large pore size distribution of membrane pores and other issues, to achieve excellent air permeability and mechanical strength, good industrial application prospects, and little difference in mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

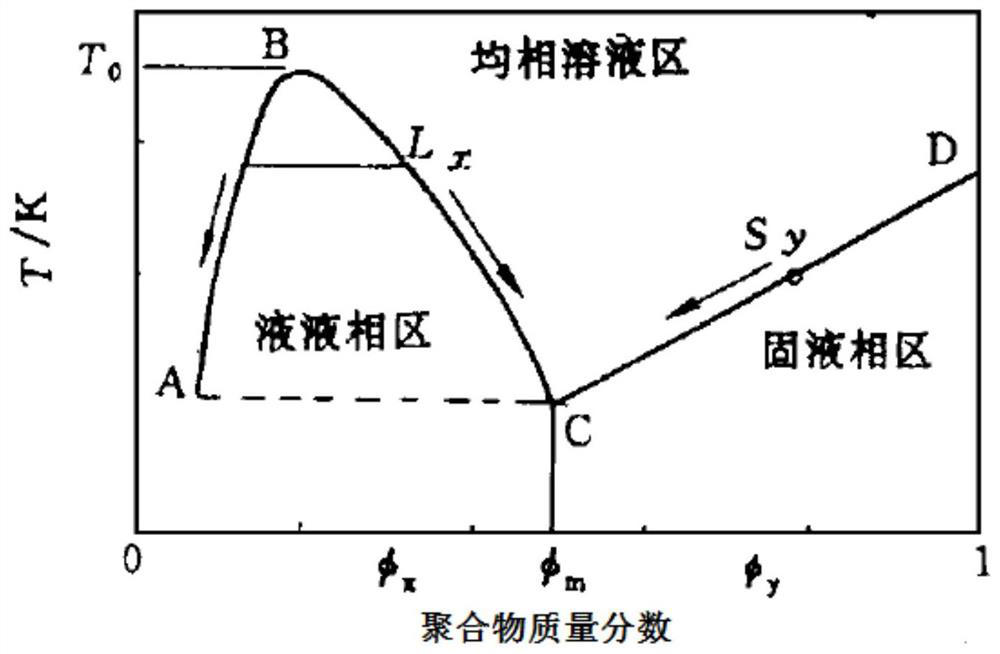

[0027] The invention provides a method for preparing a polypropylene microporous membrane, comprising: mixing polypropylene with a composite diluent to obtain a premix, wherein the polypropylene accounts for 25% to 60% by mass of the premix, The compound diluent accounts for 40% to 75% by mass of the premix; the premix is melt-extruded and cooled to form a primary film; an extractant is used to remove the primary film Composite diluent, then heat-treated to obtain the polypropylene microporous membrane; wherein, the composite diluent includes a high-temperature good solvent and a high-temperature poor solvent, and the high-temperature good solvent is selected from myristyl alcohol, cetyl alcohol, stearyl alcohol, One or more of alcohol, eicosanol; the high-temperature poor solvent is selected from one or more of benzyl alcohol, diphenyl carbonate, benzophenone and dimethyl sulfone, preferably benzophenone ; The mass percentage of the high-temperature good solvent in the comp...

Embodiment 1

[0048] Polypropylene (number-average molecular weight 50,000Da, polydispersity coefficient is 6) is mixed with composite diluent cetyl alcohol and benzophenone to form a premix, wherein the mass percentage of polypropylene is 35%, and the mass percentage of cetyl alcohol is 38%, and the mass percentage of benzophenone is 27%. The premixed material was added into a screw extruder, melted and mixed uniformly to form a film-forming liquid, wherein the melting temperature was 190°C. The film-making solution is molded by an extruder and poured into cooling water to solidify to obtain a nascent film. The cooling temperature is 25°C. The obtained nascent film is stretched horizontally and vertically, and then immersed in ethanol for extraction to remove cetyl alcohol and benzophenone. The extracted film was heat-treated in water at 90° C. for 60 min to obtain a polypropylene microporous film.

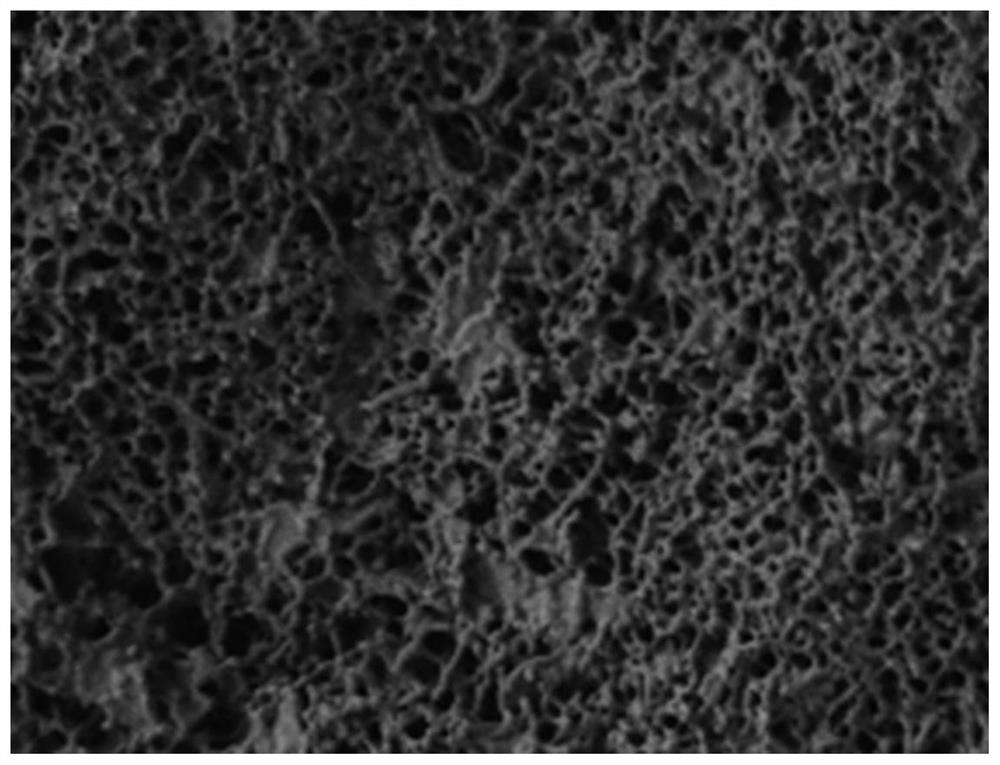

[0049] figure 2 It is the scanning electron micrograph of the polypropylene microporou...

Embodiment 2

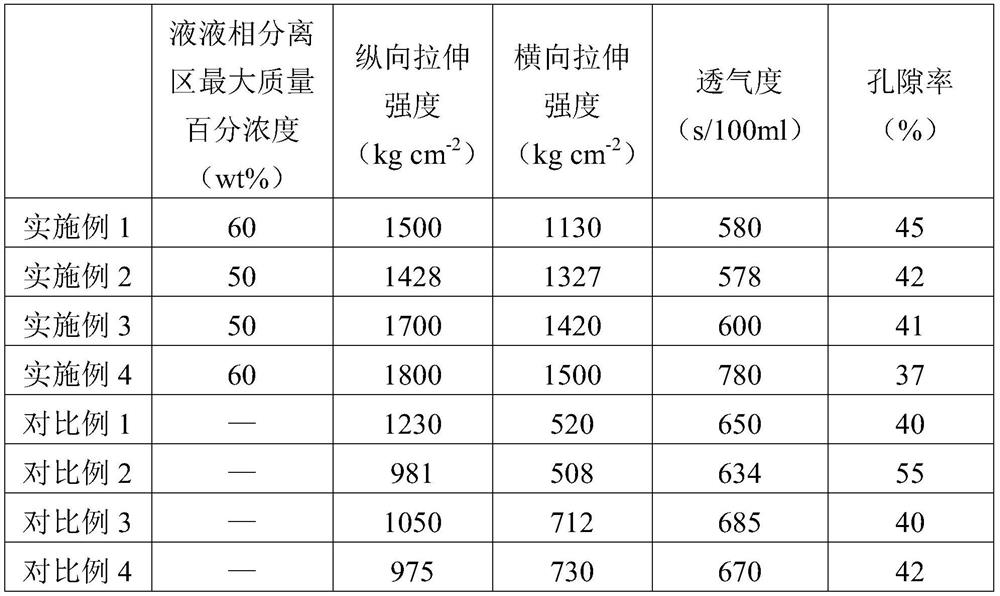

[0051] The polypropylene microporous membrane is prepared according to the method of Example 1, the difference is that the composite diluent is cetyl alcohol and diphenyl carbonate, wherein the mass percentage of polypropylene is 35%, the mass percentage of cetyl alcohol is 38%, and diphenyl carbonate The mass percentage of ester is 27%. There is a phenomenon of liquid-liquid phase separation in this system. The microporous membrane was tested for mechanical properties, air permeability and porosity. The results and the maximum polymer mass concentration corresponding to the liquid-liquid phase separation zone are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com