Ionic liquid modified CuY molecular sieve catalyst as well as preparation method and application thereof

An ionic liquid, molecular sieve technology, applied in molecular sieve catalysts, separation methods, chemical instruments and methods, etc., can solve the problems of catalyst surface blockage, poor economy, high toxicity, etc., to reduce secondary pollution, low energy consumption, and production. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of CuY molecular sieve by ion exchange method

[0023] Prepare 200 mL of CuSO with a concentration of 0.05 mol / L 4 Add 10 g of NaY molecular sieve to the solution, and adjust the pH to 9 with ammonia water. After stirring for 2 h, filter with suction, dry at 110°C, roast at 400°C, and grind to obtain CuY molecular sieve.

[0024] (2) Preparation of [EtOHmim][Cl] ionic liquid intermediate

[0025] Slowly add 0.6 mol 2-chloroethanol to 0.5 mol N-methylimidazole dropwise, stir and reflux at 80°C for 12 h to form white powder crystals, then filter, wash with ethyl acetate, and dry under vacuum at 70°C for 12 h to obtain [EtOHmim ][Cl] intermediate.

[0026] (3) [EtOHmim][NTf 2 ] Preparation of ionic liquid

[0027] Dissolve 0.3 mol of [EtOHmim][Cl] intermediate in 100 mL of water, add 0.3 mol of lithium bistrifluoromethanesulfonate imide ([LiNTf 2 ]), after stirring at room temperature for 5 h, the layer was separated and the colorless transparent liqui...

Embodiment 2

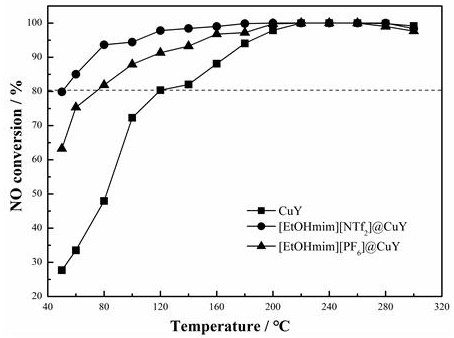

[0031] With embodiment 1 [EtOHmim] [NTf 2 ]@CuY The preparation process of the catalyst is roughly the same, the difference is that in step (3), the [EtOHmim][Cl] intermediate is dissolved in 100 mL of water and changed to acetone, and finally [EtOHmim][PF 6 ]@CuY Catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com