Preparation method of maleimide copolymer, maleimide copolymer and maleimide composition

A maleimide-based, maleamic acid technology, applied in textiles, papermaking, papermaking, coatings, etc., can solve the problems of difficult to control the appearance of solid products, increase production costs, and control a large number of costs, and reduce Environmental burden, high degree of imidization, fast and efficient aminolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

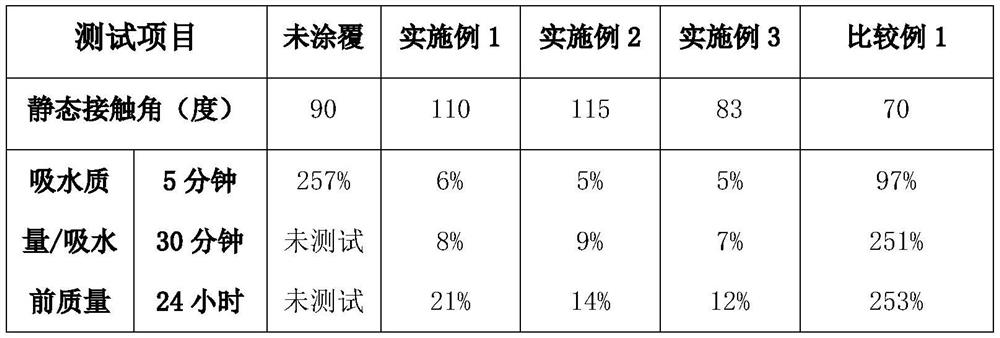

Examples

preparation example Construction

[0039] The preparation method of maleimide copolymer of the present invention comprises: a) adding the raw material that comprises comonomer, maleic anhydride, initiator in the organic solvent, makes described comonomer and described maleic anhydride carry out Reaction, to obtain maleic anhydride-based copolymer microspheres; b) amination of the maleic anhydride-based copolymer microspheres in an atmosphere of an amination gas, to obtain maleamic acid-based copolymer microspheres; c) The maleamic acid-based copolymer microspheres obtained in step b) are heated to obtain microspherical maleimide-based copolymers.

[0040] The raw materials and steps of the present invention will be described in detail below.

[0041]

[0042] In step a), raw materials including comonomer, maleic anhydride, and initiator are added to an organic solvent, so that the comonomer reacts with the maleic anhydride to separate maleic anhydride-based copolymer microspheres .

[0043] For the applicab...

Embodiment 1

[0087] Dissolve 13g of styrene and 12.25g of maleic anhydride in 200g of isoamyl acetate, add 0.2525g of dibenzoyl peroxide and react at 70°C for 3 hours. After the reaction, the product was centrifuged at 6000r / min for 10 minutes, washed with petroleum ether, centrifuged three times, and vacuum-dried to constant weight to obtain styrene-maleic anhydride copolymer microspheres. The average particle size of the microspheres is 800nm and the molecular weight is 65000. 10 g of the copolymer was added into a stainless steel reaction kettle, and 2 g of ammonia gas was introduced. Control the reaction temperature to 20° C., and react for 45 minutes to obtain styrene-maleamic acid copolymer microspheres. The product was analyzed by acid-base titration, and the amination rate of the maleic anhydride group was 99%. The stainless steel reaction kettle containing the styrene-maleamic acid copolymer microspheres was heated to 180° C., and reacted for 0.5 hour to obtain the maleimide c...

Embodiment 2

[0089] Dissolve 13g of styrene and 12.25g of maleic anhydride in 200g of isoamyl acetate, add 0.2525g of dibenzoyl peroxide and react at 70°C for 3 hours. After the reaction, the product was centrifuged at 6000r / min for 10 minutes, washed with petroleum ether, centrifuged three times, and vacuum-dried to constant weight to obtain styrene-maleic anhydride copolymer microspheres. The average particle size of the microspheres is 800nm and the molecular weight is 65000. 10 g of the copolymer was added into a stainless steel reaction kettle, and 3 g of methylamine gas was introduced. Control the reaction temperature to 30° C., and react for 0.5 hour to obtain styrene-maleamic acid copolymer microspheres. The product was analyzed by acid-base titration, and the amination rate of the maleic anhydride group was 98%. The temperature of the stainless steel reaction kettle containing the styrene-maleamic acid copolymer microspheres was increased to 160° C., and reacted for 3 hours to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com