The method for preparing lithium hydroxide from spodumene and the method for removing sodium and potassium

A technology of lithium hydroxide and spodumene, which is applied in the field of lithium extraction from ore, can solve the problems of inability to remove sodium ions, and sodium cannot be removed by washing with water, and achieves the effect of realizing industrial clean production, low cost and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

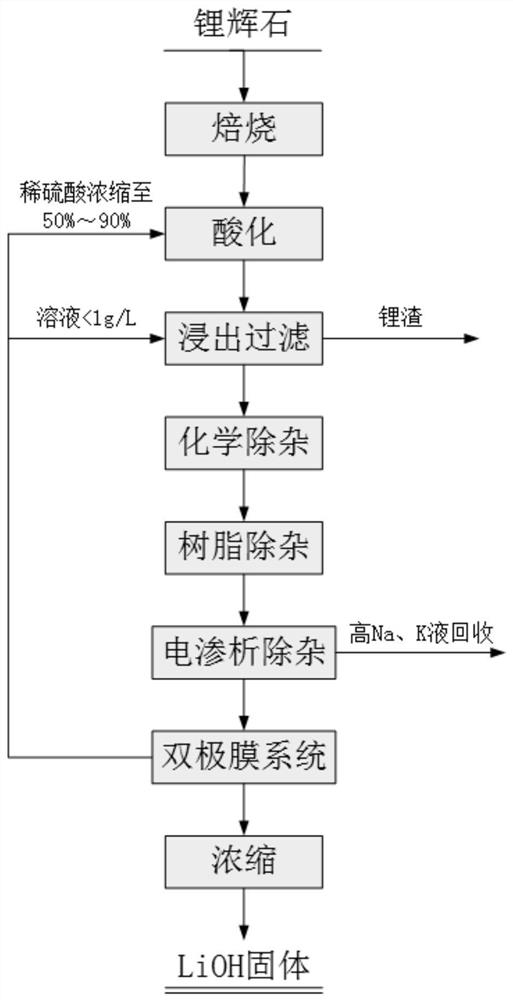

[0068] according to figure 1 The technological process in, prepares lithium hydroxide from spodumene. Specifically, spodumene concentrate (Li 2 O·Al 2 o 3 ·4Si 2 O) Calcining at 1100°C, the α-type spodumene is converted into β-type spodumene, the roasted material after conversion and roasting is cooled to below 100°C, and the roasted material is ground to 200 meshes, and the finely ground roasted material is combined with concentrated The sulfuric acid is mixed evenly at a molar ratio of 1:1.2, and then enters the acidification kiln for acidification at 240°C, and the acidification time is 2 hours. After acidification is completed, it is 1:3 to add leaching water by solid-liquid weight ratio, stirring reaction makes soluble lithium salt leaching, obtain lithium sulfate mother liquor, each ion content in the gained lithium sulfate mother liquor is shown in Table 1, and the data unit in Table 1 is g / L.

[0069] Table 1

[0070] Li 2 o

[0071] Raise the tempe...

Embodiment 2

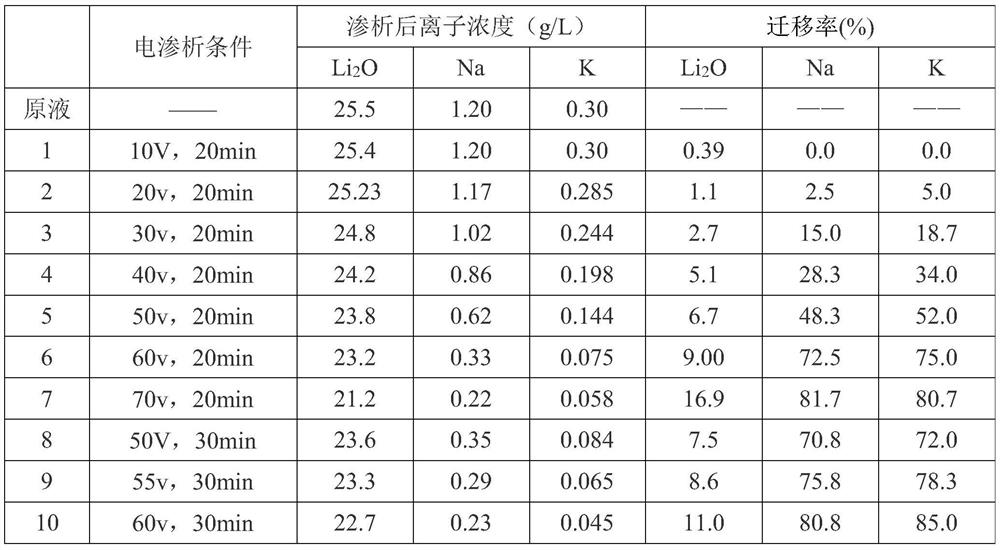

[0076] With the pre-electrolyte in Example 1 as stock solution, carry out electrodialysis under different voltages, calculate its mobility, the mobility corresponding to the electrodialysis condition of different voltages and time is shown in Table 3.

[0077] Among them, mobility=(ion concentration in stock solution-ion concentration after dialysis) / ion concentration in stock solution*100%

[0078] table 3

[0079]

[0080] It can be seen from Table 3 that when the voltage is less than 10V, the sodium and potassium in the stock solution hardly migrate out, and when the voltage is above 20V, the migration rate of sodium and potassium is significantly higher than that of lithium, and with the increase of voltage , the sodium and potassium migration rate increases, but the lithium migration rate also increases accordingly. Therefore, in order to extract the lithium in the spodumene as much as possible while increasing the sodium and potassium migration rate, the preferred vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com