Thermal power generating unit denitration system based on deep learning and optimal control method

A thermal power unit, deep learning technology, applied in neural learning methods, chemical instruments and methods, separation methods, etc., can solve the problems of air preheater scaling and corrosion, complex reaction mechanism, unsatisfactory and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

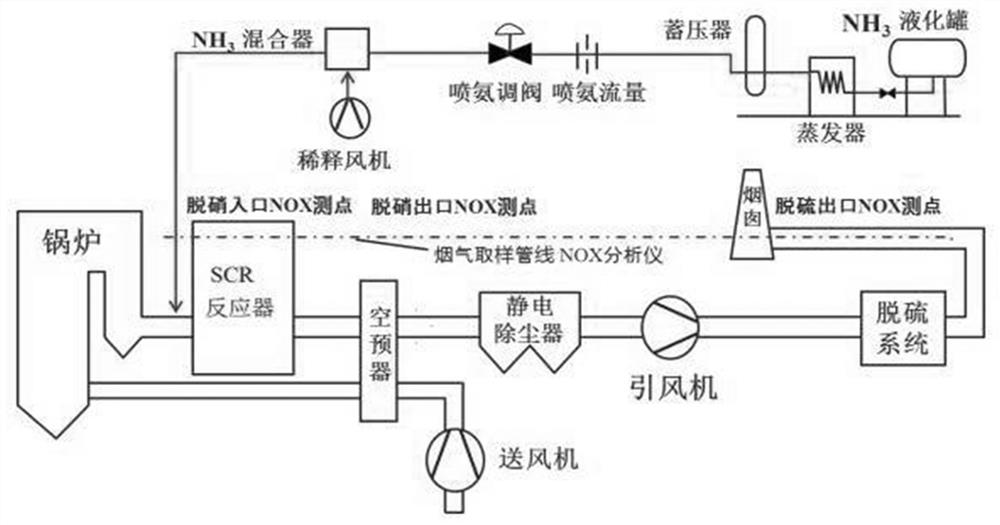

[0048] Such as figure 1 As shown, the basic flow chart of the existing SCR denitrification system is given. The SCR flue gas denitrification system is arranged between the economizer and the air preheater. The flue gas temperature in this area is usually 300-500°C. The activity is stronger, which is more conducive to the oxidation-reduction reaction of ammonia and NOx. SCR flue gas denitrification system mainly includes ammonia injection grid, deflector, rectifier, catalyst, SCR reactor, etc. The flue gas is drawn from the horizontal flue at the outlet of the economizer, enters the vertical connection of the rising flue at the entrance of the SCR reactor, mixes with the ammonia gas injected from the ammonia injection grid, passes through the rectifier vertically downward, and passes through the SCR reactor. The arranged denitrification catalyst underg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com