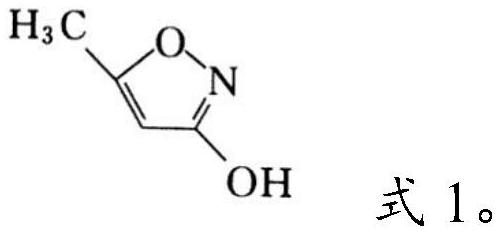

A kind of granule containing hymexazol and preparation method thereof

A technology for hymexazol and granules, which is applied in the field of hymexazal-containing granules and its preparation, and can solve the problems of hymexazol decomposition, affecting the use effect of farmers, and insufficient content of active ingredients of hymexazol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention provides the preparation method of the hymexazol-containing granule described in the above technical scheme, comprising the following steps:

[0034] dissolving hymexazol in an organic solvent to obtain hymexazol liquid;

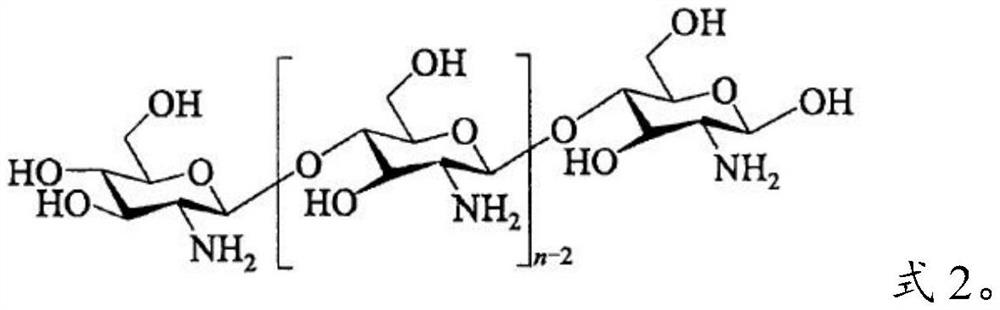

[0035] mixing the amino oligosaccharin and the anti-caking agent, and pulverizing them into powder to obtain the amino oligosaccharin medicinal powder;

[0036] Spraying the hymexazol liquid onto carrier particles under the condition of 65°C to 70°C to obtain carrier particles with hymexazol adsorbed thereon, the carrier particles being calcium ammonium nitrate;

[0037] The oligoaminosaccharin medicinal powder is mixed with the carrier particles adsorbed with hymexazol for coating and granulation to obtain the hymexazol-containing granules.

[0038] In the present invention, hymexazol is dissolved in an organic solvent to obtain hymexazol liquid. In the present invention, the organic solvent is preferably ethanol and / or methan...

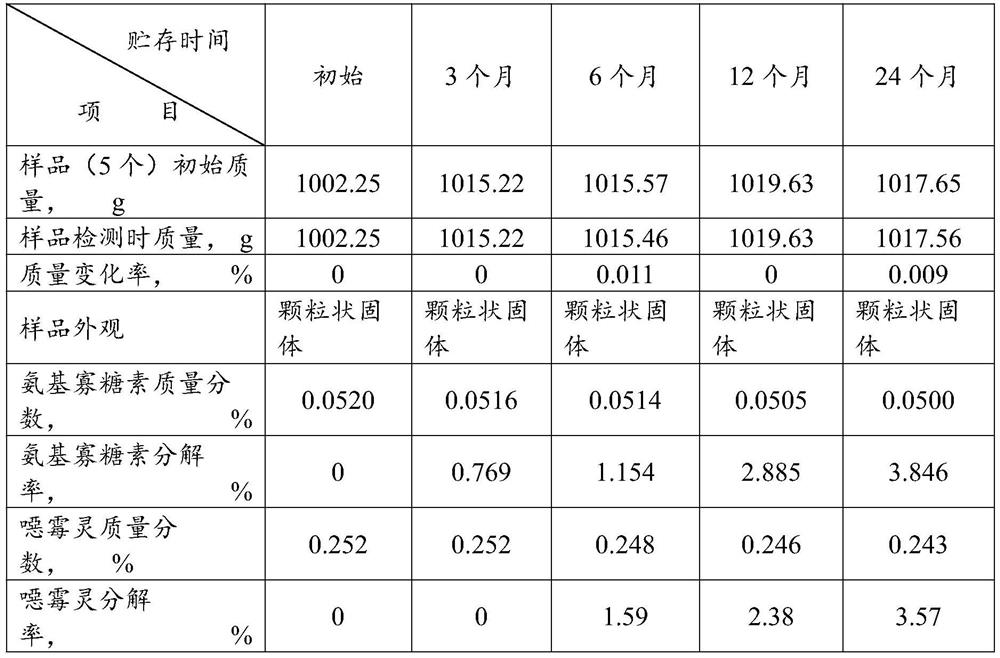

Embodiment 1

[0045] A kind of described granule containing hymexazol, the preparation method is as follows:

[0046] (1) 0.26kg of hymexazol is dissolved with 500mL ethanol to obtain hymexazol liquid;

[0047] (2) Mix 0.057 kg of amino oligosaccharin and 1 kg of anti-caking agent (silicon dioxide) and pulverize into a fine powder with a particle size of less than 45 μm to obtain amino oligosaccharin medicated powder;

[0048] (3) Start the disc granulator, turn on the heating cycle device, and when the oil temperature reaches 70°C, put 100kg of calcium ammonium nitrate (particle size 4.0-1.4mm) into the disc granulator; then step (1) The hymexazol medicinal liquid was sprayed onto the calcium ammonium nitrate granules through a high-pressure spray gun for adsorption, and after the spraying was finished, the mixing was continued for 20 minutes, and the amino oligosaccharin medicinal powder in step (2) was added to the disc granulator for coating and granulation. Hymexazol-containing granul...

Embodiment 2

[0056] A kind of described granule containing hymexazol, the preparation method is as follows:

[0057] (1) 0.25kg of hymexazol is dissolved with 500mL ethanol to obtain hymexazol liquid;

[0058] (2) Mix 0.056 kg of amino oligosaccharin and 1 kg of anti-caking agent (silicon dioxide) and pulverize into a fine powder with a particle size of less than 45 μm to obtain amino oligosaccharin medicated powder;

[0059] (3) Start the disc granulator, turn on the heating cycle device, and when the oil temperature reaches 70°C, put 100kg of calcium ammonium nitrate (particle size 4.0-1.4mm) into the disc granulator; then step (1) The hymexazol medicinal liquid was sprayed onto the calcium ammonium nitrate granules through a high-pressure spray gun for adsorption, and after the spraying was finished, the mixing was continued for 20 minutes, and the amino oligosaccharin medicinal powder in step (2) was added to the disc granulator for coating and granulation. Hymexazol-containing granul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com