Catalytic device and organic waste gas treatment system

A technology of organic waste gas and catalytic devices, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve problems such as explosions and VOC accidents, and achieve the effect of preventing explosion hazards and realizing self-cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

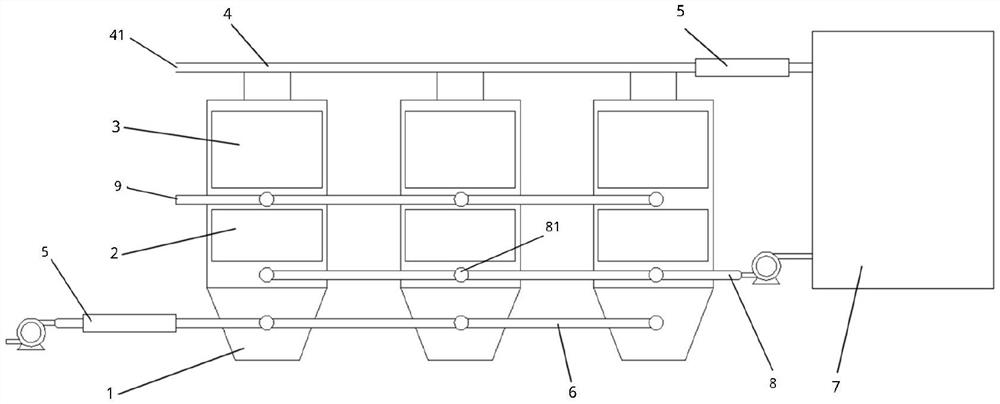

[0030] A catalytic device, characterized in that, comprising:

[0031] Reactor 1, inside the reactor 1, a filter 2 and an adsorption catalyst 3 are sequentially arranged along the flow direction of the organic waste gas;

[0032] The filter 2 is a wall-flow silicon carbide ceramic filter, and the load on the filter 2 includes: manganese oxide 1%-3%, cerium oxide 0.5%-1%, cobalt oxide 0.5%-1%, Palladium 0.3%-0.5% and platinum 0.3%-0.5%; with filtering and catalytic functions, it can filter out heavy oil, particles, and droplets in VOC exhaust gas. At the same time, it has a catalytic function at 300°C, which can catalyze and oxidize VOC waste gas into water and carbon dioxide.

[0033] The adsorption catalyst 3 includes the following components: 23%-25% of ZSM-5 molecular sieve, 25%-35% of beta zeolite molecular sieve, 10%-30% of activated alumina, 8%-12% of nanometer manganese oxide, zinc oxide 2 %-4%, iron oxide 3%-6%, palladium 0.3%-0.5% and platinum 0.3%-0.5%, with filter...

Embodiment 2

[0035] An organic waste gas treatment system, characterized in that it comprises:

[0036] The combustion chamber 7 is connected with an intake pipeline, and the intake pipeline is divided into two sections, the first pipeline 6 and the second pipeline 4; the combustion chamber is used for incinerating organic waste gas.

[0037] The catalytic device described in Embodiment 1 is arranged between the first pipeline 6 and the second pipeline 4;

[0038] The first pipeline 6 connects the intake end of the catalytic device and the exhaust gas source, the second pipeline 4 is connected between the gas outlet end of the catalytic device and the combustion chamber 7, and the second pipe A combustion-supporting air inlet 41 is also provided on the road 4 . The organic waste gas whose concentration has been reduced by catalysis is mixed with the combustion-supporting air and then blown into the combustion chamber.

Embodiment 3

[0040] On the basis of embodiment 2, increase:

[0041] A flame arrester 5, the first pipeline 6 and the second pipeline 4 are both provided with a flame arrester 5 . Further preferably, the flame arrester is formed by extruding silicon carbide, and the flame arrester is honeycomb-shaped and has a ceramic macroporous structure with a length of 4-6 meters. The flame arrester has the characteristics of high-temperature catalysis and dispersion of VOC gas, ensuring the safety of gas transmission.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com