Coupling use method utilizing various industrial solid/dangerous wastes

A technology of industrial and waste cathode carbon blocks, which is applied in the direction of solid waste removal, chemical instruments and methods, aluminum compounds, etc., and can solve the problem of low comprehensive utilization efficiency of valuable components and difficulty in a large amount of consumption and recycling of various industrial wastes Use and other issues to achieve the effect of reducing weight, reducing energy consumption, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

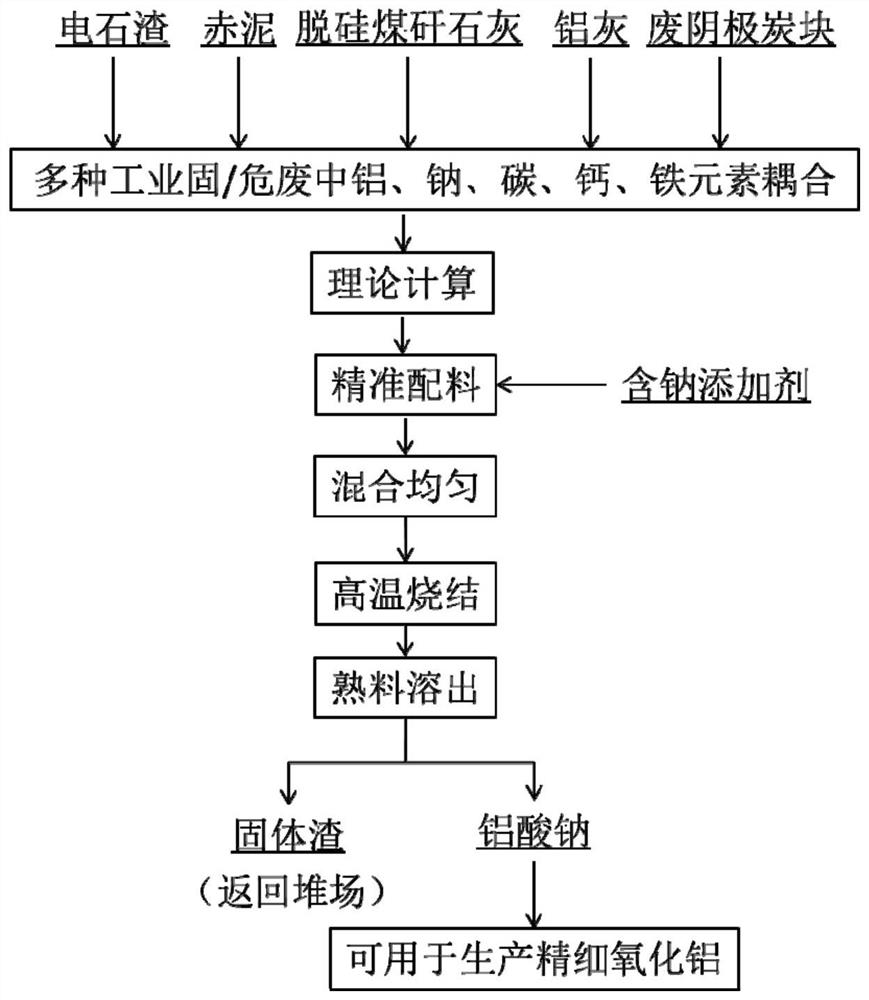

Embodiment 1

[0038] use as figure 1 In the method shown, the pre-desiliconized coal gangue ash, aluminum ash, red mud, spent cathode carbon block, carbide slag, and sodium-containing additives are uniformly mixed in a mass ratio of 34:6:10:4:23:23; the mixed Uniform raw meal is calcined at 1000°C for 30 minutes at high temperature. After the calcined clinker is dissolved, sodium aluminate solution and solid slag can be obtained. After analysis, the standard alumina dissolution rate of clinker is 92.2%, and the standard sodium oxide of clinker is 92.2%. The dissolution rate was 94.5%.

Embodiment 2

[0040] use as figure 1 In the method shown, the pre-desiliconized coal gangue ash, aluminum ash, red mud, spent cathode carbon block, carbide slag, and sodium-containing additives are uniformly mixed in a mass ratio of 29:5:9:3:33:21; the mixed Uniform raw meal is calcined at 1100°C for 60 minutes at high temperature. After the calcined clinker is dissolved, sodium aluminate solution and solid slag can be obtained. After analysis, the standard alumina dissolution rate of clinker is 92.5%, and the standard sodium oxide standard of clinker is 92.5%. The dissolution rate was 94.2%.

Embodiment 3

[0042] use as figure 1 In the method shown, the pre-desiliconized coal gangue ash, aluminum ash, red mud, spent cathode carbon block, carbide slag, and sodium-containing additives are uniformly mixed in a mass ratio of 24:6:8:4:39:19; the mixed The uniform raw meal is calcined at 1200°C for 90 minutes at a high temperature. After the calcined clinker is dissolved, sodium aluminate solution and solid slag can be obtained. After analysis, the standard alumina dissolution rate of the clinker is 93.1%, and the standard sodium oxide of the clinker is 93.1%. The dissolution rate was 94.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com