Method for modifying polyaniline polymer

A technology of polyaniline and polymer, which is applied in the field of polyaniline polymer modification, and can solve problems such as the electrical conductivity not meeting the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take a 25mL two-necked flask, add 300mg of C in sequence 60 and 3mL of fuming sulfuric acid, heated to 55°C, and reacted for 70h under nitrogen protection to obtain a suspension; after cooling to room temperature, add the suspension dropwise to absolute ethanol in an ice bath, and centrifuge After standing still, the intermediate product can be obtained; take a 50mL round bottom flask, add ultrapure water to the intermediate product for hydrolysis reaction, N 2 Heat to 85°C and react for 8 hours; use a sand core filter device to obtain a brown solid, and wash it repeatedly with ultrapure water for 3 times, and finally place it in a vacuum drying oven to obtain a fullerene derivative C 60 (OH) 12 .

[0022] 170mg of aniline was added to a two-necked flask, followed by 100mg of sodium dodecylsulfonate (as an emulsifier), 4mL of 2mol / L hydrochloric acid and 15mL of ultrapure water, and finally (0mg, 20mg, 100mg) of Fullerene Derivative C 60 (OH) 12 , stirred vigorousl...

Embodiment 2

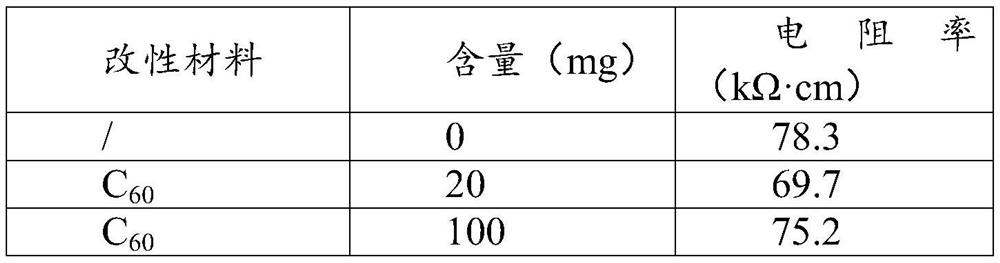

[0029] 170mg of aniline was added to a two-necked flask, followed by 100mg of sodium dodecylsulfonate (as an emulsifier), 4mL of 2mol / L hydrochloric acid and 15mL of ultrapure water, and finally (0mg, 20mg, 100mg) of Fullerene C 60 , stirred vigorously for 2 h under ice-water bath conditions.

[0030] Dissolve 0.4g of ammonium persulfate in 15mL of ultrapure water, add dropwise into the reaction flask to control the temperature at 80-90°C and continue the reaction for 3h; finally add polylactic acid solution (a solution formed by dissolving 1.2g of polylactic acid solid in chloroform solvent) ), 90-95 ° C vigorously stirred and reacted for 3 hours, the reaction product was washed with ethanol and ultrapure water until the water phase was colorless, to remove remaining monomers and ammonium persulfate, etc.; use a rotary evaporator to extract the obtained oil The phase product was spin-dried to obtain the target product, which was placed in a vacuum drying oven for 12 hours to...

Embodiment 3

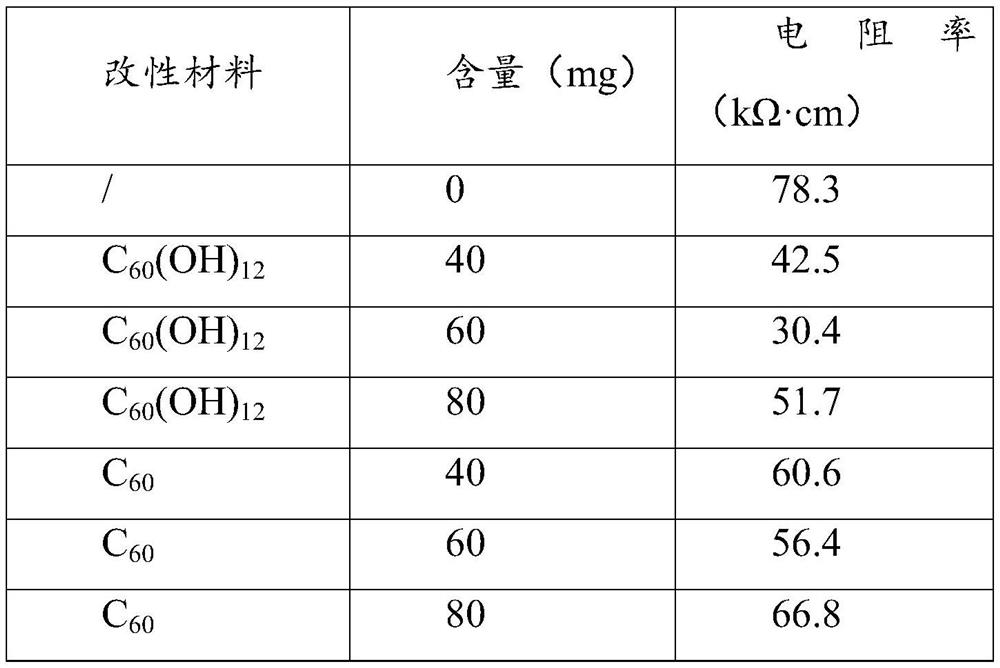

[0036] 170mg of aniline was added to a two-necked flask, followed by 100mg of sodium dodecylsulfonate (as an emulsifier), 4mL of 2mol / L hydrochloric acid and 15mL of ultrapure water, and finally (40mg, 60mg, 80mg) of Fullerene C 60 or fullerene derivative C 60 (OH) 12 , stirred vigorously for 2 h under ice-water bath conditions.

[0037] Dissolve 0.4g of ammonium persulfate in 15mL of ultrapure water, add dropwise into the reaction flask to control the temperature at 80-90°C and continue the reaction for 3h; finally add polylactic acid solution (a solution formed by dissolving 1.2g of polylactic acid solid in chloroform solvent) ), 90-95 ° C vigorously stirred and reacted for 3 hours, the reaction product was washed with ethanol and ultrapure water until the water phase was colorless, to remove remaining monomers and ammonium persulfate, etc.; use a rotary evaporator to extract the obtained oil The phase product was spin-dried to obtain the target product, which was placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com