Preparation of a polyionic liquid functionalized mofs material and its application in the synthesis of isopulegol

A polyionic liquid, functionalized technology, applied in the reduction preparation of oxygen-containing functional groups, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve the problem of excessive catalyst dosage, slow reaction rate and harsh reaction conditions. and other problems, to achieve the effect of excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

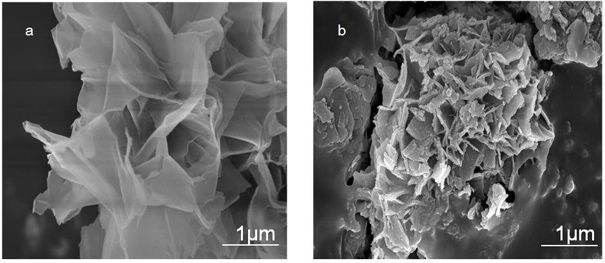

[0030] (1) Preparation of UiO material

[0031] Uniformly disperse 0.6 mmol of imidazole-4,5-dicarboxylic acid, 1.2 mmol of terephthalic acid, and 1.2 mmol of zirconium chloride in 42 mL of DMF, then add 3 mL of glacial acetic acid and sonicate, then pour into 100 mL of polytetrafluoroethylene Crystallization was carried out at 130 °C for 24 h in an ethylene-lined hydrothermal synthesis kettle. After cooling down to room temperature, it was centrifuged, washed twice with DMF and five times with methanol, and the solid powder obtained by drying was the UiO material.

[0032] (2) Preparation of UiO-prePIL material

[0033] Disperse 0.12 mmol of UiO material in ethanol, add 0.06 mmol of epichlorohydrin, and polymerize at 80°C for 72h. After cooling down to room temperature, it was centrifuged, washed five times with ethanol, and the solid powder obtained after drying was UiO-prePIL.

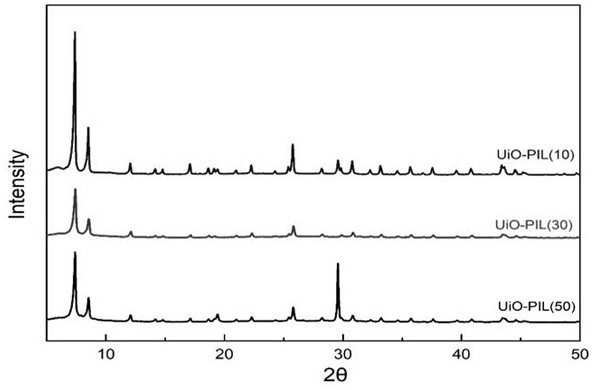

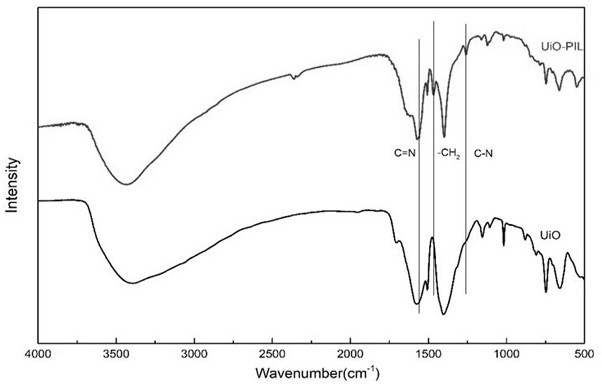

[0034] (3) Preparation of UiO-PIL materials

[0035] Disperse 0.06mmol UiO-prePIL in ethanol...

Embodiment 2

[0042] Application: Take 0.05g of the synthetic material in Example 1, disperse it in 3ml of ethanol solution, add 0.5g of citronellal, and react at 30°C for 2h. After determination, under the above-mentioned reaction conditions, the yield of isopulegol is 92.67%.

Embodiment 3

[0044] (1) Preparation of UiO material

[0045] Uniformly disperse 0.6 mmol of imidazole-4,5-dicarboxylic acid, 1.2 mmol of terephthalic acid, and 1.2 mmol of zirconium chloride in 42 mL of DMF, then add 3 mL of glacial acetic acid and sonicate, then pour into 100 mL of polytetrafluoroethylene Crystallization was carried out at 130 °C for 24 h in an ethylene-lined hydrothermal synthesis kettle. After cooling down to room temperature, it was centrifuged, washed twice with DMF and five times with methanol, and the solid powder obtained by drying was the UiO material.

[0046] (2) Preparation of UiO-prePIL material

[0047] Disperse 0.12 mmol of UiO material in ethanol, add 0.06 mmol of epichlorohydrin, and polymerize at 80°C for 72h. After cooling down to room temperature, it was centrifuged, washed five times with ethanol, and the solid powder obtained after drying was UiO-prePIL.

[0048] (3) Preparation of UiO-PIL materials

[0049] Disperse 0.06mmol UiO-prePIL in ethanol, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com