Laser additive manufacturing method capable of conveniently obtaining fine equiaxed grains

An equiaxed grain and laser additive technology, which is applied in laser additive manufacturing of metal materials and in the field of laser additive manufacturing, can solve problems such as difficulty in completely ensuring product quality consistency, changes in material characteristics, and unfavorable comprehensive performance, and achieve suitable Effects on mass industrial production and high-performance manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

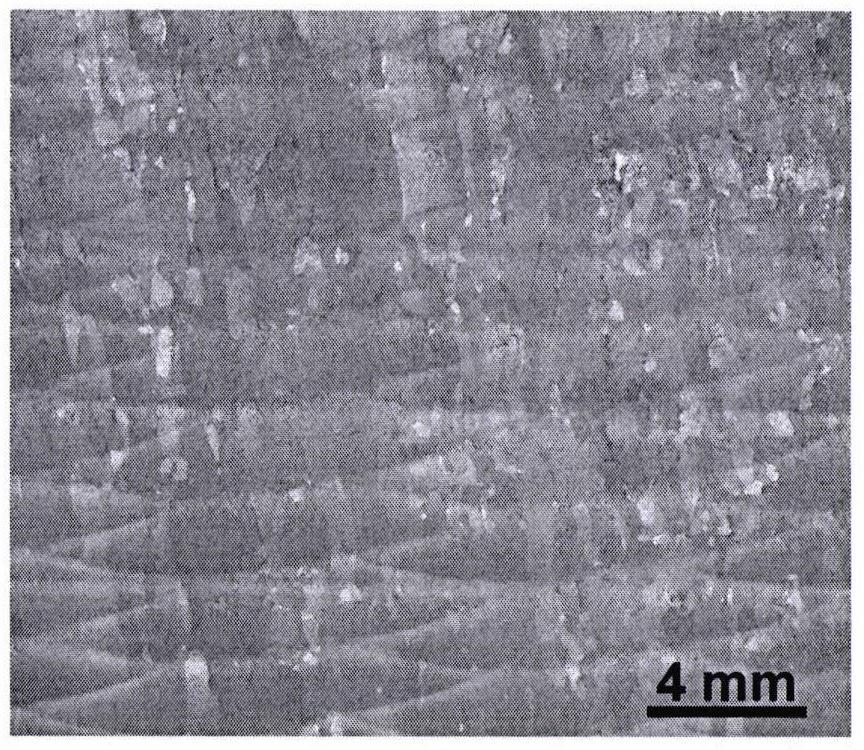

[0027] Such as figure 1 As shown, taking laser additive manufacturing of Ti-6.5Al-3.5Mo-1.5Zr-0.3Si titanium alloy as an example, a laser additive manufacturing method that can conveniently obtain fine equiaxed grains is characterized in that it includes the following steps:

[0028] In the first step, the titanium alloy powder with a particle size distribution of 160-240 μm and an oxygen content greater than 0.08% is loaded into the powder feeder;

[0029] In the second step, the substrate is fixed on the workbench of an inert processing chamber filled with argon gas, and the purity of argon gas is not less than 99.999%;

[0030] In the third step, when the argon oxygen content in the working room is less than 30ppm, the additive manufacturing of titanium alloy is started;

[0031] In the fourth step, under the action of laser, the titanium alloy powder is melted and deposited on the substrate;

[0032] In the fifth step, after the deposition is completed, the argon protect...

Embodiment 2

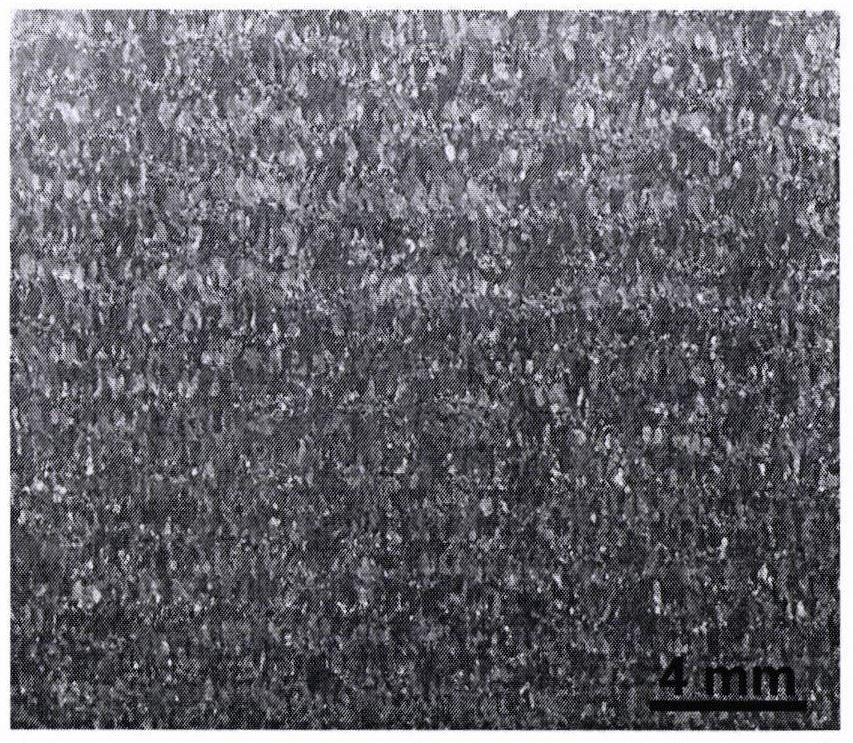

[0037] A laser additive manufacturing method that can conveniently obtain fine equiaxed grains is characterized in that it comprises the following steps:

[0038] In the first step, the titanium alloy powder with a particle size distribution of 160-240 μm and an oxygen content greater than 0.08% is loaded into the powder feeder;

[0039] In the second step, the substrate is fixed on the workbench of an inert processing chamber filled with argon gas, and the purity of argon gas is not less than 99.999%;

[0040] In the third step, when the argon oxygen content in the working room is less than 30ppm, the additive manufacturing of titanium alloy is started;

[0041] In the fourth step, under the action of laser, the titanium alloy powder is melted and deposited on the substrate;

[0042] In the fifth step, after the deposition is completed, the argon protection chamber is opened, and the deposited titanium alloy is taken out;

[0043] The sixth step is to put the deposited tita...

Embodiment 3

[0047] A laser additive manufacturing method that can conveniently obtain fine equiaxed grains is characterized in that it comprises the following steps:

[0048] In the first step, the titanium alloy powder with a particle size distribution of 160-240 μm and an oxygen content greater than 0.08% is loaded into the powder feeder;

[0049] In the second step, the substrate is fixed on the workbench of an inert processing chamber filled with argon gas, and the purity of argon gas is not less than 99.999%;

[0050] In the third step, when the argon oxygen content in the working room is less than 30ppm, the additive manufacturing of titanium alloy is started;

[0051] In the fourth step, under the action of laser, the titanium alloy powder is melted and deposited on the substrate;

[0052] In the fifth step, after the deposition is completed, the argon protection chamber is opened, and the deposited titanium alloy is taken out;

[0053] The sixth step is to put the deposited tita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Dislocation density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com