Preparation process of silicon heterojunction solar cell

A preparation process and technology for solar cells, applied in sustainable manufacturing/processing, circuits, electrical components, etc., can solve problems affecting the long-term reliability of components, and achieve the effect of ensuring long-term reliability, ensuring contact, and good mechanical contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

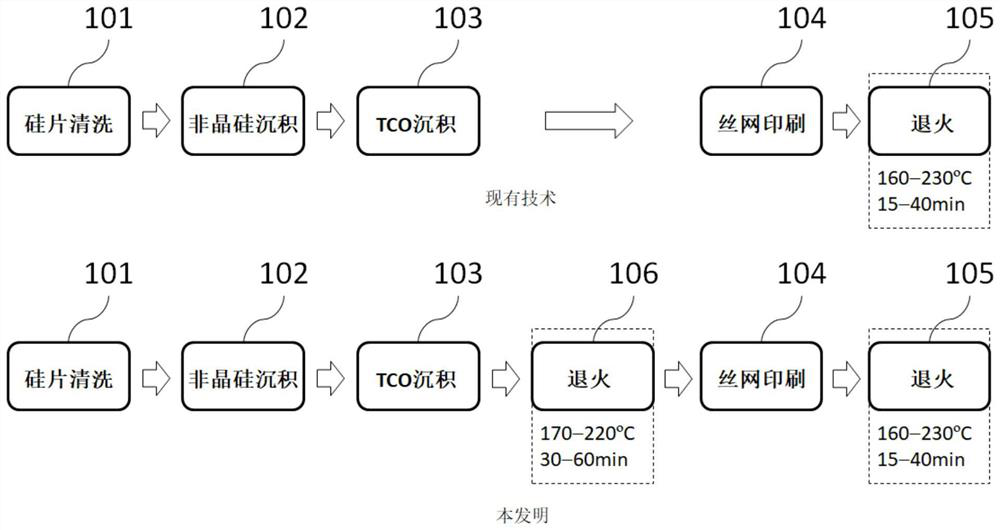

[0031] see figure 1 , this embodiment provides a two-step annealing process design for a high-efficiency silicon heterojunction solar cell, and the manufacturing process of the cell includes:

[0032] 1) Use the standard RCA cleaning process to remove organic matter and metal ions on the surface of the silicon wafer;

[0033] 2) Place the RCA-cleaned silicon wafer in 2% HF aqueous solution for 2-5 minutes to remove the natural oxide layer on the surface;

[0034] 3) Place the above-mentioned silicon wafer in a drying machine with a nitrogen protection atmosphere, and shake off the remaining water stains on the surface;

[0035] 4) Deposit 4 to 7 nanometers of intrinsic a-Si:H or a-SiO:H on both surfaces of the clean silicon wafer respectively, and the growth process adopts PECVD or Cat-CVD;

[0036] 5) Deposit 4-7nm N-type and P-type a-Si:H or a-SiO:H on the surface of two intrinsic a-Si:H or a-SiO:H respectively, and the growth process adopts PECVD or Cat-CVD ;

[0037] 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com