A rare earth-based nanocomposite hydrogel wound dressing and its preparation method and application

A nano-composite and hydrogel technology, applied in pharmaceutical formulations, bandages, drug delivery, etc., can solve problems such as wound healing and tissue regeneration that have not been reported before, achieve good biological effects, convenient operation, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method of europium oxide-based nanocomposite hydrogel wound dressing of the present invention comprises the following steps:

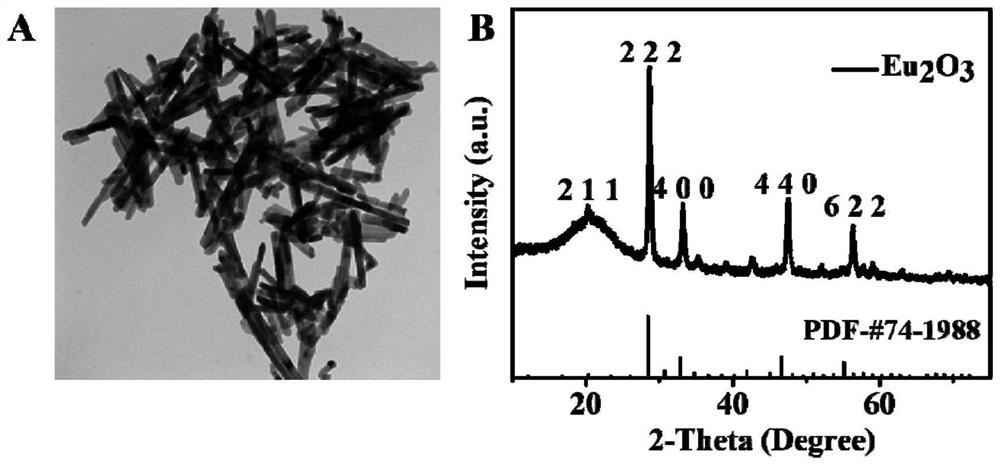

[0035] 1) First use hydrothermal reaction to prepare europium hydroxide nanorods, first add europium nitrate to deionized water, stir and dissolve at room temperature, then adjust pH to 8~9 with 1M sodium hydroxide, then continue stirring at room temperature for 30-60 Minutes, and then put it into an oven at 120~200 ℃ for 12-48 hours. After the reaction is finished, it is washed with water and ethanol in sequence, and then vacuum-dried to obtain europium hydroxide. Europium hydroxide was calcined at 600°C for 3-5 hours to obtain europium oxide nanorods, which were stored in a vacuum desiccator for further use.

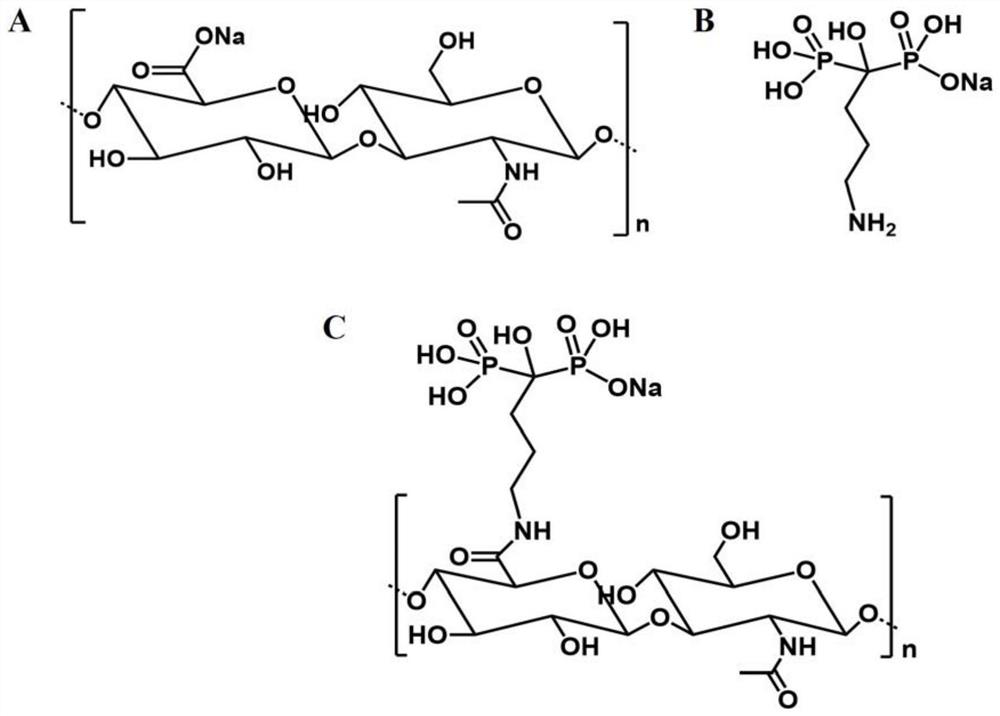

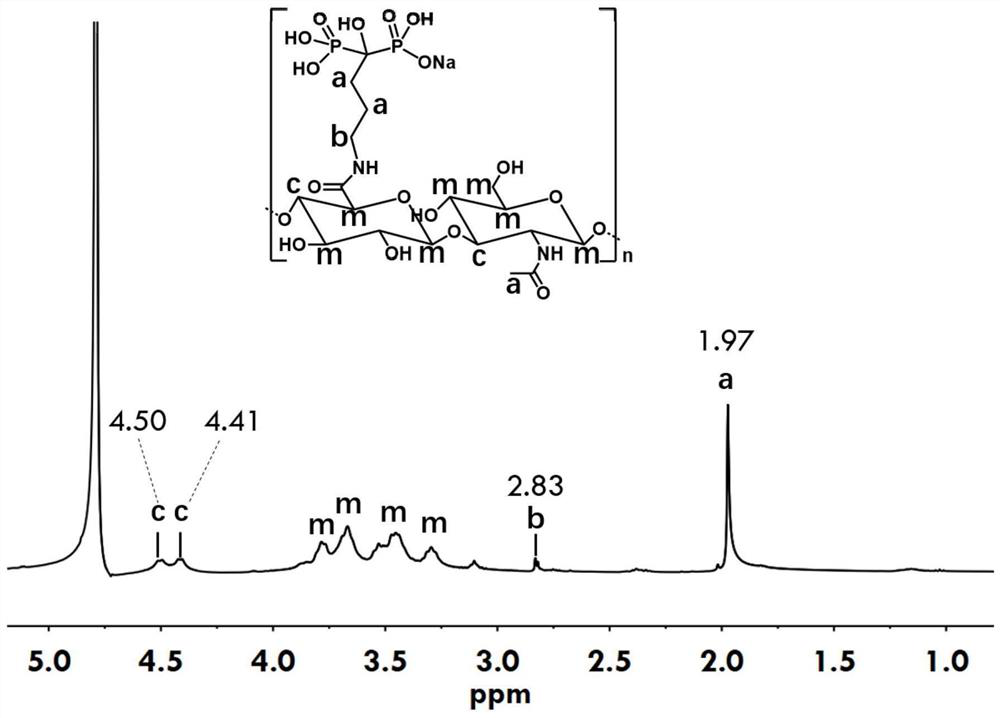

[0036] 2) Dissolve sodium hyaluronate in MES buffer (pH=5~6) and stir to dissolve, activate with NHS and EDC, after 10~14 hours, add sodium alendronate and continue stirring for 2~3 days, of which The molar ratio of sodiu...

Embodiment 1

[0045] 1) The preparation method of europium oxide nanorods: first add europium nitrate to deionized water, stir and dissolve at room temperature, then adjust the pH to 8~9 with 1M sodium hydroxide, then continue to stir at room temperature for 30-60 minutes, and then put it in an oven React at 120°C for 12 hours. After the reaction is finished, it is washed with water and ethanol in sequence, and then vacuum-dried to obtain europium hydroxide. Calcining europium hydroxide at 600°C for 4 hours to obtain europium oxide nanorods, which were stored in a vacuum desiccator for further use;

[0046] 2) Preparation method of HA-AL polymer: dissolve 1 mmol sodium hyaluronate in MES buffer (pH=5~6) and stir to dissolve, activate with NHS and EDC, after 12 hours, add 3 mmol into Al The sodium lendronate continued to stir for 2~3 days; finally, the hyaluronic acid-alendronate sodium polymer (HA-AL) obtained by the reaction was purified for 2~3 days with a dialysis tube (10kDa). HA-AL pol...

Embodiment 2

[0056] 1) The preparation method of terbium oxide nanorods: first add terbium nitrate into deionized water, stir and dissolve at room temperature, then adjust the pH to 8~9 with 1M sodium hydroxide, then continue to stir at room temperature for 30-60 minutes, and then put Reaction in an oven at 200°C for 16 hours. After the reaction is finished, it is washed with water and ethanol in sequence, and then vacuum-dried to obtain europium hydroxide. Calcining terbium hydroxide at 600°C for 3 hours to obtain terbium oxide nanorods, which were stored in a vacuum desiccator for further use;

[0057] 2) Preparation method of HA-AL polymer: dissolve 1 mmol sodium hyaluronate in MES buffer (pH=5~6) and stir to dissolve, activate with NHS and EDC, add 4 mmol alendron after 12 hours Sodium phosphonate continued to stir for 2~3 days; finally, the hyaluronic acid-alendronate sodium polymer (HA-AL) obtained by the reaction was purified for 2~3 days with a dialysis tube (10kDa). HA-AL polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com