Preparation method of zeolite applied to water pollution treatment

A water pollution and zeolite technology, applied in the direction of microorganism-based methods, methods using microorganisms, water pollutants, etc., can solve the problems of failure to fundamentally eliminate water pollutants and secondary pollution, and achieve improved removal of pollutants The ability of ions, avoiding secondary pollution, and increasing the effect of ion exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

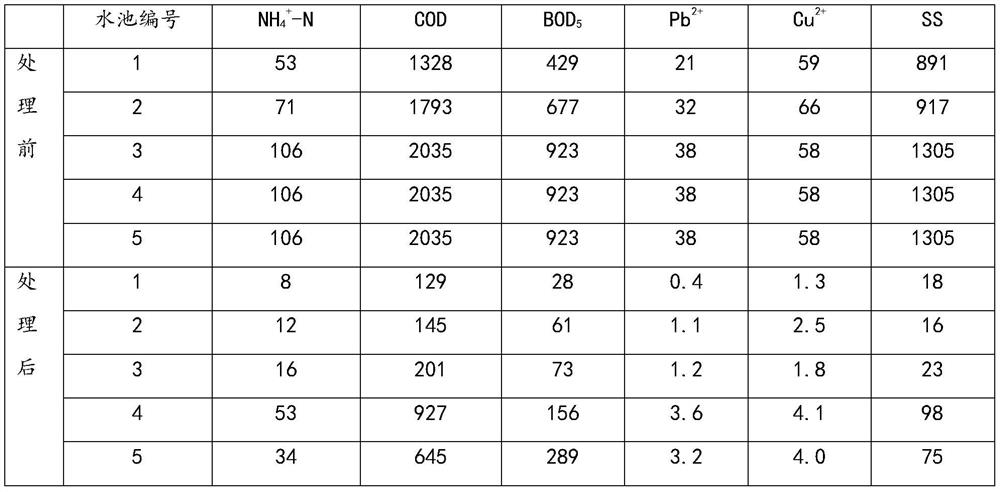

Examples

Embodiment 1

[0031] A kind of zeolite preparation method that this embodiment is applied to water pollution treatment comprises:

[0032] (1) soaking the natural zeolite with a particle diameter of 5mm in HCl solution with a concentration of 0.3mol / L for 24h, and then soaking with a NaOH solution with a concentration of 0.3mol / L for 24h;

[0033] (2) The soaked zeolite was steamed at 300° C. for 1 hour, and then rinsed with deionized water until pH=7.0;

[0034] (3) The zeolite after washing is subjected to secondary soaking treatment in the modified solution for 20 hours. In the modified solution, the concentration of sodium citrate is 0.2mol / L, and the concentration of NaCl is 0.5mol / L;

[0035] (4) The zeolite after the second immersion treatment was distilled at 300°C for 1 hour, and then washed with deionized water to pH=7.0 to obtain a modified zeolite;

[0036] (5) The modified zeolite is placed in the microbial culture solution in the bioreactor and cultivated for 30 hours to obta...

Embodiment 2

[0041] A kind of zeolite preparation method that this embodiment is applied to water pollution treatment comprises:

[0042] (1) soaking the natural zeolite with a particle diameter of 5mm in HCl solution with a concentration of 0.1mol / L for 24h, and then soaking with a NaOH solution with a concentration of 0.5mol / L for 8h;

[0043] (2) The soaked zeolite was steamed at 80° C. for 8 hours, and then rinsed with deionized water to pH=7.0;

[0044] (3) The zeolite after washing is soaked twice in the modified solution for 5 hours. In the modified solution, the concentration of sodium citrate is 1.2mol / L, and the concentration of NaCl is 1.0mol / L;

[0045] (4) The zeolite after the second immersion treatment was steamed at 80° C. for 6 hours, and then washed with deionized water to pH=7.0 to obtain a modified zeolite;

[0046] (5) The modified zeolite is placed in the microbial culture solution in the bioreactor and cultivated for 15 hours to obtain the modified biological zeolit...

Embodiment 3

[0049] A kind of zeolite preparation method that this embodiment is applied to water pollution treatment comprises:

[0050] (1) the natural zeolite with particle diameter is 3mm with the HN of concentration 0.2mol / L 3 Soak in solution for 20 hours, and then soak in KOH solution with a concentration of 0.3mol / L for 15 hours;

[0051] (2) The soaked zeolite was steamed at 200° C. for 2 hours, and then rinsed with deionized water until pH=7.0;

[0052] (3) The zeolite after washing is subjected to secondary soaking treatment in the modified solution for 15 hours, in the modified solution, the concentration of sodium citrate is 0.8mol / L, and the concentration of NaCl is 0.6mol / L;

[0053] (4) The zeolite after the second immersion treatment was steamed at 200° C. for 2 hours, and then washed with deionized water to pH=7.0 to obtain a modified zeolite;

[0054] (5) The modified zeolite is placed in the microbial culture solution in the bioreactor and cultivated for 20 hours to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com