Zr-Ti-Nb alloy and preparation method thereof

A zr-ti-nb, alloy technology, applied in the field of powder metallurgy, can solve problems such as difficult to meet the requirements of space movable components, low strength of Zr alloy, composition segregation, etc., to avoid coarse structure, high density and uniform structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a preparation method for the Zr-Ti-Nb alloy described in the above technical solution, comprising the following steps:

[0042] mixing Zr source powder, Ti source powder and Nb source powder to obtain mixed powder;

[0043] Compressing the mixed powder to obtain a molded green body;

[0044] In a protective atmosphere, sintering the shaped green body to obtain a sintered green body;

[0045] In a protective atmosphere, the sintered compact is subjected to hot isostatic pressing to obtain the Zr-Ti-Nb alloy.

[0046] The present invention mixes Zr source powder, Ti source powder and Nb source powder to obtain mixed powder.

[0047] In the present invention, the Zr source powder preferably includes Zr and ZrH 2 A mixture or Zr, when the Zr source powder preferably includes Zr and ZrH 2 A mixture of the Zr and ZrH 2 The mass ratio of is preferably 1:10 to 10:1. In the present invention, the particle size of the Zr source powder is ...

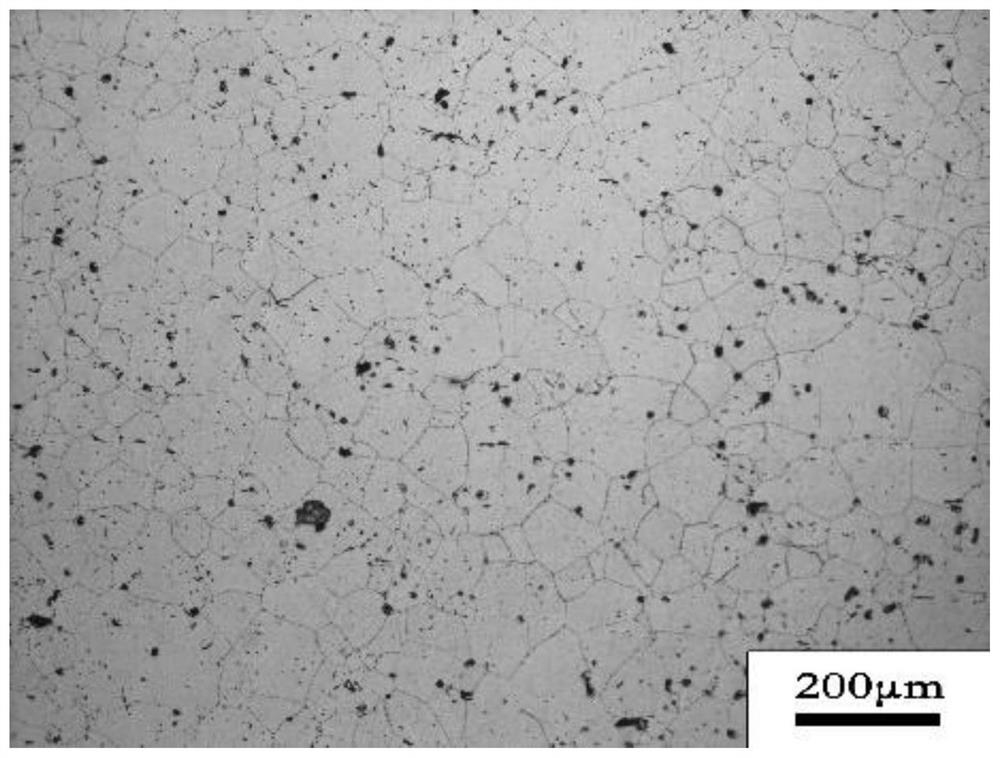

Embodiment 1

[0069] Weigh, Zr powder with a particle size of 10 μm, Ti powder with a particle size of 10 μm, and TiH with a particle size of 15 μm 2 Powder, Nb powder with a particle size of 10 μm, among which, Zr powder, Ti powder, TiH 2 The mass ratio of the powder to the Nb powder is 3:2:2:3. The above-mentioned powder is ball milled on a planetary ball mill, and the ball mill tank is evacuated by a vacuum pump. The vacuum time is 2min, and the ball mill speed is 200r / min. The time is 6h, the ball-to-material ratio is 3:1, the diameter of the grinding ball is 10mm, and the mixed powder is obtained;

[0070] The obtained mixed powder is pressed into shape by a cold isostatic pressing process, the pressure is 200MPa, and the pressure holding time is 30min to obtain a shaped green body;

[0071] The obtained molded body was sintered in a protective atmosphere. The sintering process was as follows: at a heating rate of 7 °C / min, the temperature was raised from room temperature to 500 °C, k...

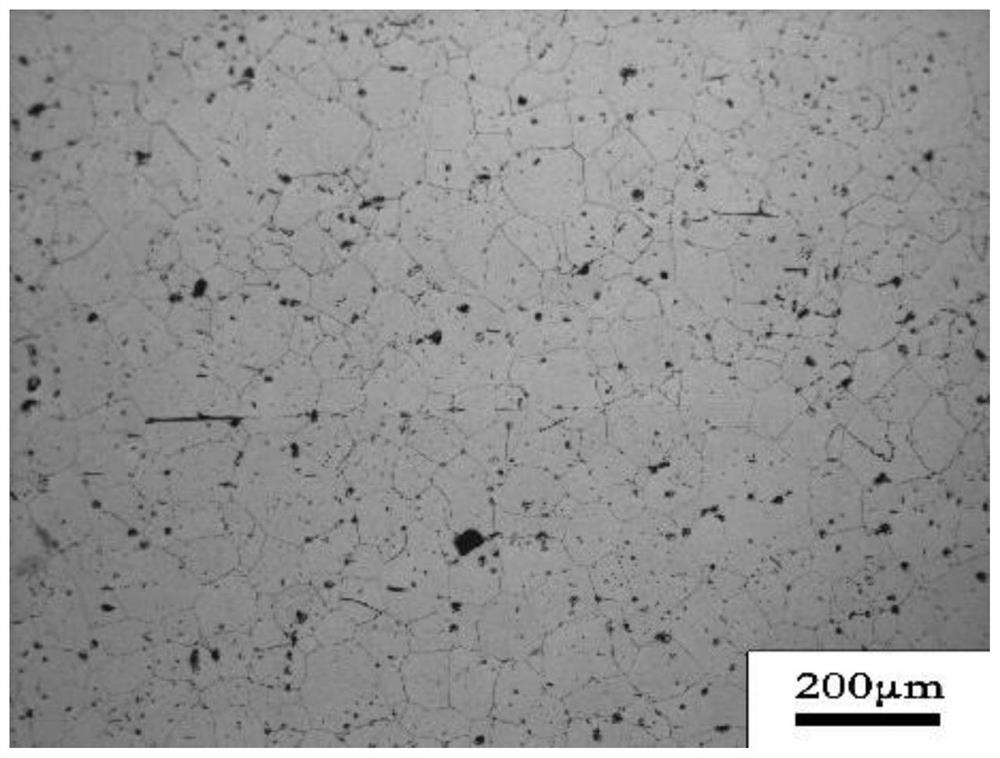

Embodiment 2

[0075] Weigh Zr powder with a particle size of 10 μm, ZrH with a particle size of 15 μm 2 Powder, Ti powder with a particle size of 10 μm, Nb powder with a particle size of 20 μm, among which Zr powder, ZrH 2 The mass ratio of powder, Ti powder and Nb powder is 3:3:6:8. The above powder is ball milled on a planetary ball mill, and the ball mill tank is evacuated by a vacuum pump. The vacuum time is 2min, and the ball mill speed is 250r / min, the ball milling time is 3h, the ball-to-material ratio is 5:1, and the diameter of the ball is 10mm to obtain the mixed powder;

[0076] The obtained mixed powder is pressed into shape by cold isostatic pressing process, the pressure is 300MPa, and the holding time is 15min, to obtain the formed green body;

[0077] The obtained molded body was sintered in a protective atmosphere. The sintering process was as follows: at a heating rate of 8 °C / min, the temperature was raised from room temperature to 500 °C, kept for 1 h, and then at a he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com