Anti-counterfeiting Lyocell fiber, preparation method and anti-counterfeiting method

A fiber and cellulose pulp technology, applied in the field of anti-counterfeit fibers, can solve the problems of inability to track anti-counterfeit fibers, moderate anti-counterfeiting effects, and no technical disclosure of the use of amino acid metal chelates. perceived effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

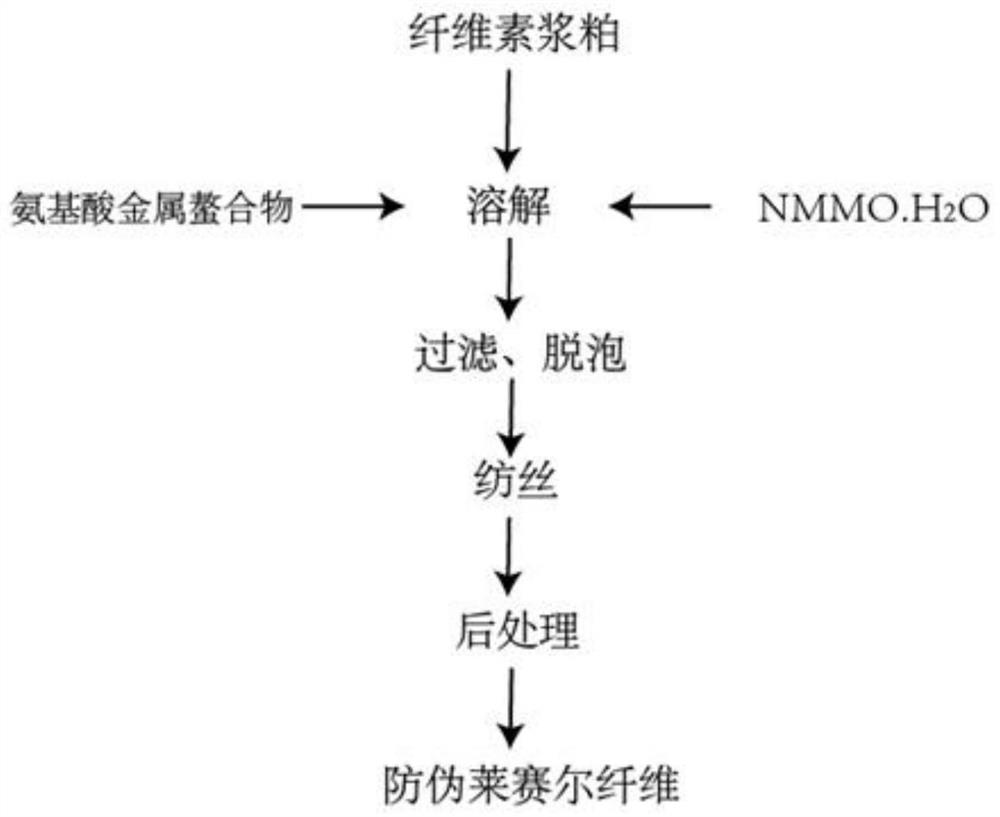

[0032] Such as figure 1 Shown, the preparation method of anti-counterfeit lyocell fiber of the present invention comprises the following steps:

[0033] (1) Provide amino acid metal chelate: take the metal compound to be chelated and the ligand amino acid respectively, add deionized water to mix, fully stir to make a suspension, adjust the pH to neutral or slightly alkaline, pulverize, homogenize Quality, filtration to obtain a suspension with a solid particle size less than 30 microns; the suspension is injected into a high-pressure liquid nanomill with a high-pressure pump, the pressure is 90-130MPa, the feed rate is 1.6-5 liters per minute, and the reaction is 0.5-1.5 Hours, obtained Amino acid chelate clear night. After spray drying, the finished product of amino acid metal chelate is obtained. Among them, the amino acid can be lysine, tryptophan, phenylalanine, leucine, isoleucine, threonine, methionine, valine, aspartic acid, glutamic acid, glycine or a combination th...

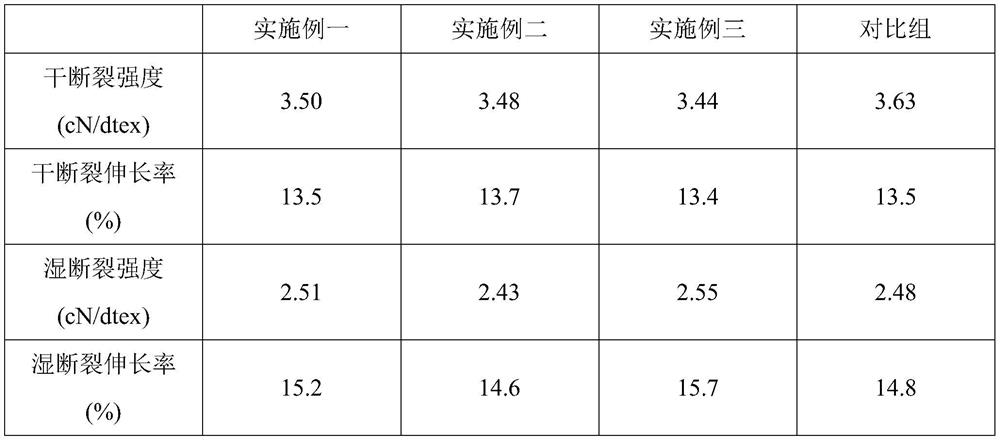

Embodiment 1

[0042] The preparation method of anti-counterfeiting lyocell fiber is as follows:

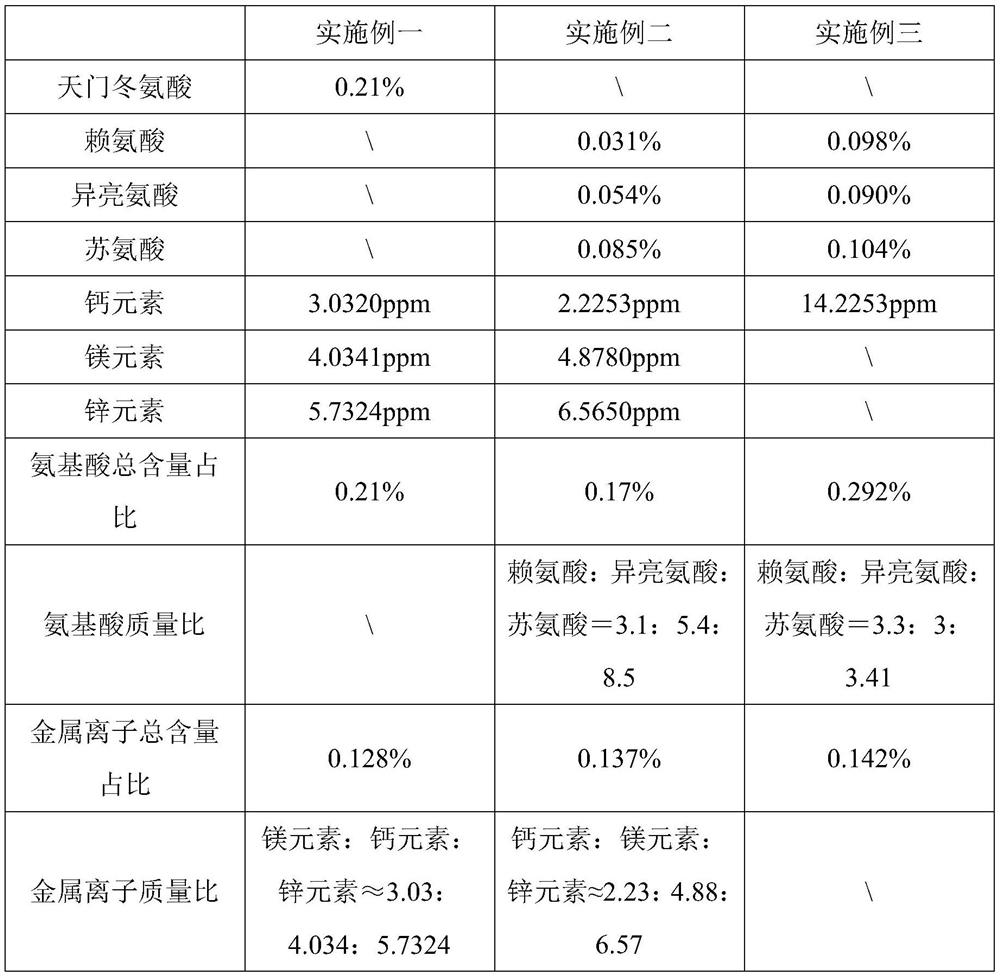

[0043] (1) Preparation of anti-counterfeiting tracking agent: Ca(OH) 2 , Mg(OH) 2 , Zn(OH) 2 Mix with aspartic amino acid respectively, according to the above sequence, the molar ratio of the three hydroxides is 1:2:3, and each metal compound and amino acid are dosed according to the molar ratio of 1:2. According to the mass ratio of the above-mentioned reactant to water as 25:75, stir fully after mixing, adjust the pH of the mixed solution to 7.8, and process through colloid milling and homogenizer to fully dissolve and diffuse the reactant, and further filter the suspension to make The solid particles in the suspension are less than 30 microns, and then the suspension is injected into a high-pressure liquid nanomill, the pressure is controlled at 100 MPa, the feed rate is 3 liters per minute, and the reaction is performed for one hour to obtain aspartic acid chelated calcium and aspartic amin...

Embodiment 2

[0047] Prepare anti-counterfeit lyocell fibers according to the method of Example 1, the difference is that in step (1), three kinds of amino acids are selected to be mixed with different metal compounds, specifically Ca(OH) 2 Mixed with Lysine, Mg(OH) 2 Mixed with Isoleucine, Zn(OH) 2 It is mixed with threonine, and each metal compound and the corresponding ligand amino acid are dosed in a molar ratio of 2:3. The amino acid metal chelate used in step (2) is changed accordingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com