A Catalytic Particulate Filter for Diesel Engines Coated with Cezrk/RGO Nano Solid Solution Catalyst

A particle trap and solid solution technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, nanotechnology, etc., can solve the problem of high catalyst cost, achieve good catalytic activity and improve efficiency , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

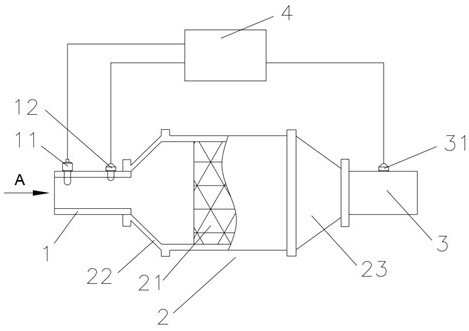

[0054] A catalytic particle filter for diesel engines coated with CeZrK / rGO nanometer solid solution catalyst, comprising a filter housing 2 and a filter element 21, the filter element 21 includes a substrate and a catalyst; the active component of the catalyst includes CeZrK / rGO nanometer solid solution catalyst.

[0055] Further, the CeZrK / rGO nano solid solution catalyst has a general formula: Ce A Zr B K C / rGO; wherein, in the general formula, A:B:C=5:1~3:1~3.

[0056] The CeZrK / rGO nanometer solid solution catalyst has a nanopore structure, and its pore diameter is 36.1-36.9nm. It is larger than soot (>20nm), which ensures that soot can enter the internal pores of the catalyst and fully contact with the active phase.

[0057] The specific surface area of CeZrK / rGO nano solid solution catalyst is 117.2-152.4m 2 / g. The graphene-based catalyst has a larger specific surface area and better pore structure, which effectively ensures the high catalytic activity of the C...

Embodiment 2

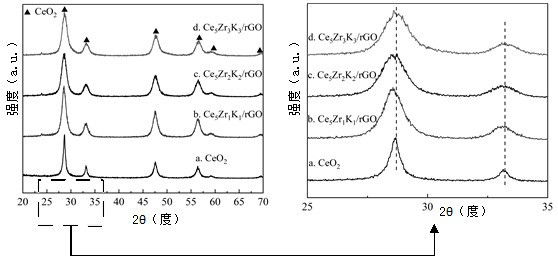

[0069] Such as figure 2 As shown, the present embodiment describes the morphology and size of the CeZrK / rGO nanometer solid solution catalyst using transmission electron microscopy (TEM) technology. It can be seen that the base material of graphene takes the form of translucent flakes with wrinkles and folds. The metal oxide particles supported on graphene are uniform and highly dispersed. From figure 2 can be found in the TEM image, with Ce 5 Zr 1 K 1 / rGO and Ce 5 Zr 3 K 3 / rGO vs Ce 5 Z r2 k 2 / rGO has the most uniform dispersion of metal oxide particles. Ce can be obtained using nanometer measurement software 5 Zr 1 K 1 / rGO, Ce 5 Zr 2 K 2 / rGO, and Ce 5 Zr 3 K 3 The average particle diameters of / rGO are 9.65nm, 7.42nm and 9.39nm, respectively, which are 15-20nm smaller than the average particle diameters of CeZrOx catalysts. This indicates that graphene inhibits the surface migration of metal oxide nanoparticles and reduces the size of metal oxide ...

Embodiment 3

[0073] This example uses N 2 The characteristics of CeZrK / rGO nano solid solution catalyst were analyzed by adsorption-desorption experiment. Figure 4 shows the N of the CeZrK / rGO nano-solid solution catalyst 2 Adsorption isotherm and pore size distribution line graph. Since adsorption and diffusion are key processes in heterogeneous catalytic reactions, the pore structure of CeZrK / rGO nano-solid solution catalysts has a great influence on its catalytic performance. In the IUPAC classification, the similar type IV isotherm with H3 type hysteresis loop indicates that the CeZrK / rGO nano-solid solution catalyst is characterized by mesoporous distribution. exist Figure 4 As can be seen from b, d and f of 5 Zr 1 K 1 / rGO, Ce 5 Zr 2 K 2 / rGO and Ce 5 Zr 3 K 3 The most likely pore diameters of / rGO are 36.9nm, 36.8nm, and 36.1nm, respectively, which are larger than soot (>20nm), which ensures that soot can enter the internal pores of the CeZrK / rGO nano-solid solution cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com