Preparation method and application of modified lignin-based hard carbon microspheres

A lignin-based, lignin-based technology, applied in the field of modified lignin-based hard carbon microspheres and its preparation, can solve the problems of high cost of hard carbon preparation and difficulty in commercial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

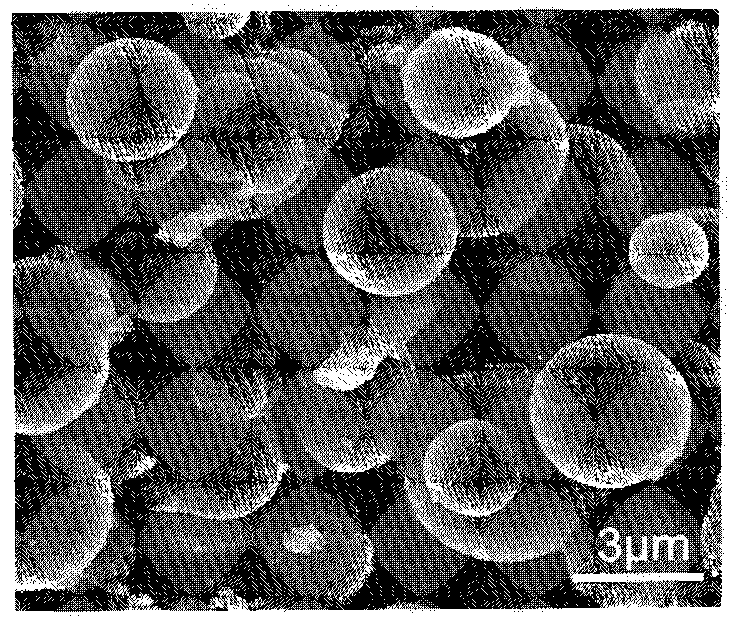

Image

Examples

Embodiment 1

[0039] 1. Preparation of lignin solution: Weigh sodium lignosulfonate and phenol into a beaker equipped with a magnet and 40 mL of distilled water, then place it on a magnetic stirrer and stir thoroughly at room temperature for 1 hour to obtain lignin with a solid content of 2%. prime solution.

[0040] Wherein, the mass of phenol in the lignin solution accounts for 30% of the total mass of sodium lignosulfonate and phenol.

[0041] 2. The lignin solution is transferred to a polytetrafluoroethylene reactor with a volume of 70mL, then the polytetrafluoroethylene reactor is put into a stainless steel hydrothermal kettle and sealed, and then the stainless steel hydrothermal kettle is placed in an oven Raise the temperature to 200°C and keep it warm for 14h. Turn off the power and cool down naturally.

[0042] 3. The solution obtained by the hydrothermal reaction was centrifuged and washed several times until the supernatant was colorless, and the black precipitate was taken and...

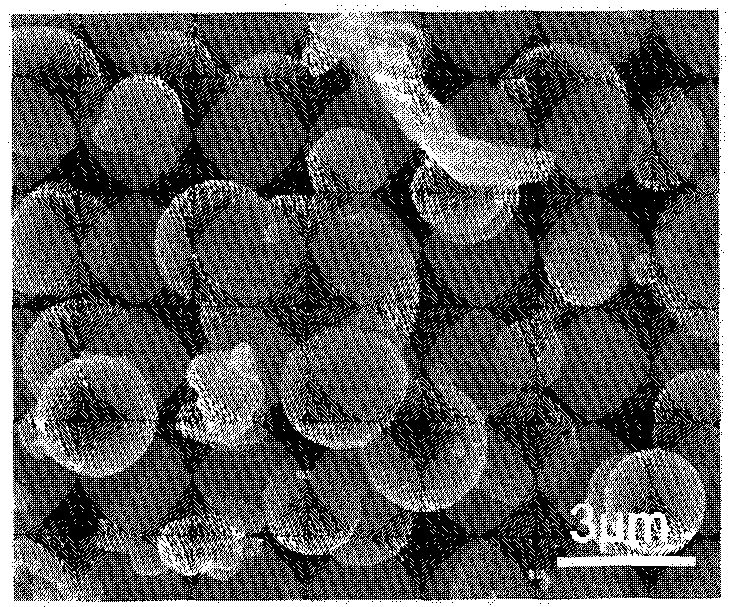

Embodiment 2

[0045]1. Preparation of lignin solution: Weigh sodium lignosulfonate and 3-aminophenol into a beaker with a magnet and 40mL of distilled water, then place it on a magnetic stirrer and stir at room temperature for 1 hour to obtain a solid content of 5 % lignin solution.

[0046] Wherein, the mass of 3-aminophenol in the lignin solution accounts for 10% of the total mass of sodium lignosulfonate and 3-aminophenol.

[0047] 2. The lignin solution is transferred to a polytetrafluoroethylene reactor with a volume of 70mL, then the polytetrafluoroethylene reactor is put into a stainless steel hydrothermal kettle and sealed, and then the stainless steel hydrothermal kettle is placed in an oven Raise the temperature to 250°C and keep it warm for 12h. Turn off the power and cool down naturally.

[0048] 3. The solution obtained by the hydrothermal reaction was centrifuged and washed several times until the supernatant was colorless, and the black precipitate was taken and dried in a ...

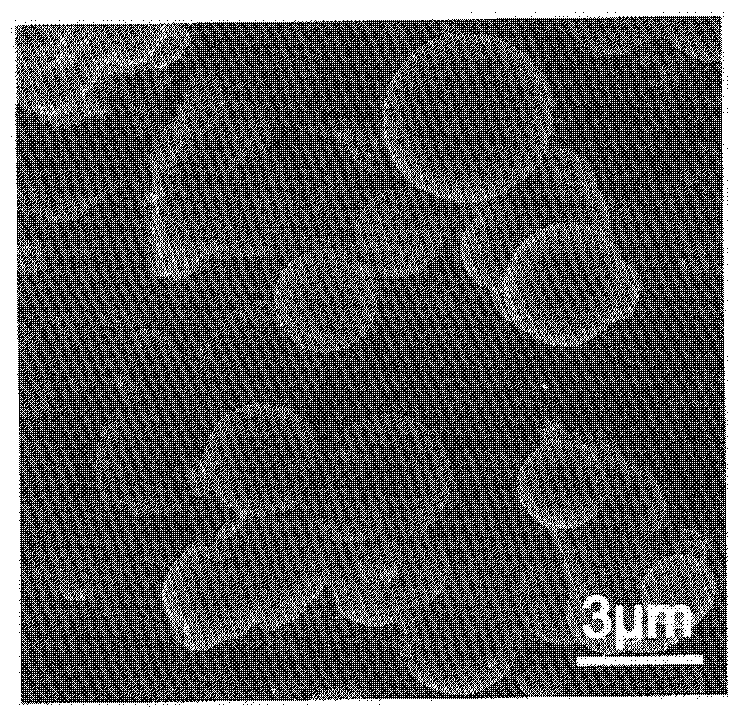

Embodiment 3

[0051] 1. Preparation of lignin solution: Weigh sodium lignosulfonate and resorcinol into a beaker equipped with magnets and 40mL distilled water, then place it on a magnetic stirrer and stir thoroughly at room temperature for 1 hour to obtain a solid content of 20%. lignin solution.

[0052] Wherein, the mass of 3-aminophenol in the lignin solution accounts for 70% of the total mass of sodium lignosulfonate and 3-aminophenol.

[0053] 2. The lignin solution is transferred to a polytetrafluoroethylene reactor with a volume of 70mL, then the polytetrafluoroethylene reactor is put into a stainless steel hydrothermal kettle and sealed, and then the stainless steel hydrothermal kettle is placed in an oven Raise the temperature to 120°C and keep it warm for 60h. Turn off the power and cool down naturally.

[0054] 3. The solution obtained by the hydrothermal reaction was centrifuged and washed several times until the supernatant was colorless, and the black precipitate was taken ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com