Multi-dimensional data fusion and quantitative modeling method for metal additive manufacturing process system

A manufacturing process and metal additive technology, applied in the field of data processing, can solve the problems affecting the stability of the additive manufacturing process and the comprehensive performance of components, low practicability of self-learning ability, strong coupling effect, etc., and achieve efficient model calculation, analysis and prediction. Accurate, conducive to data storage, self-learning and self-optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

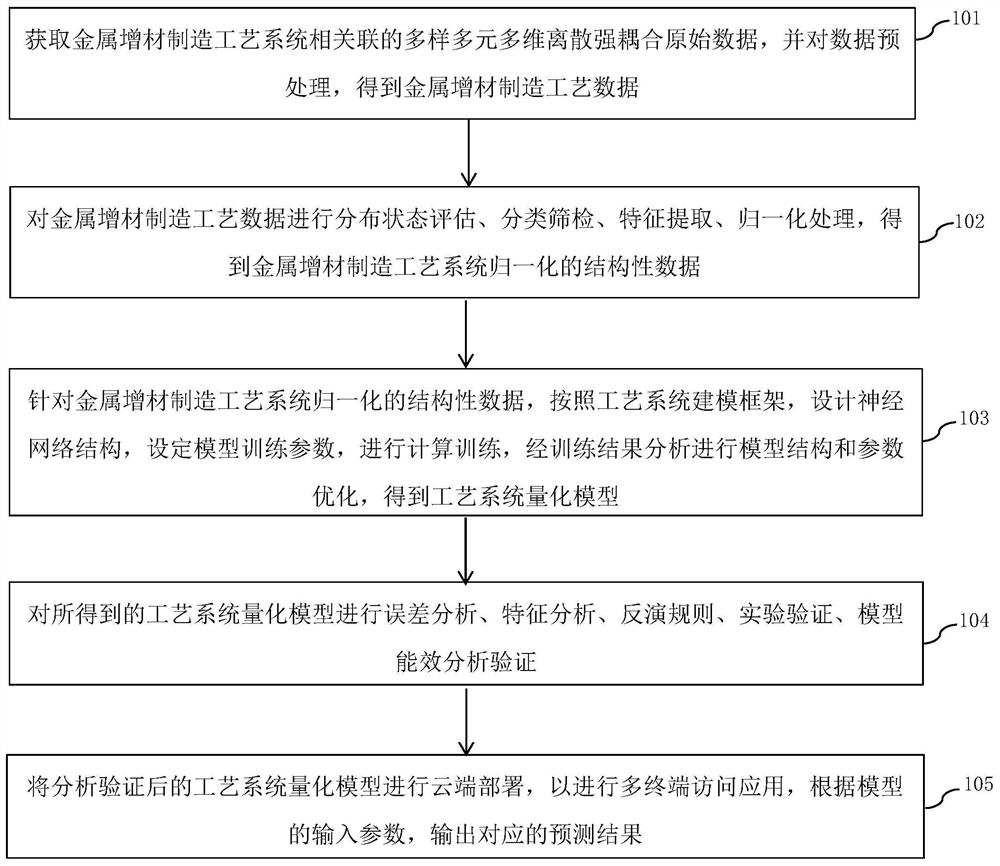

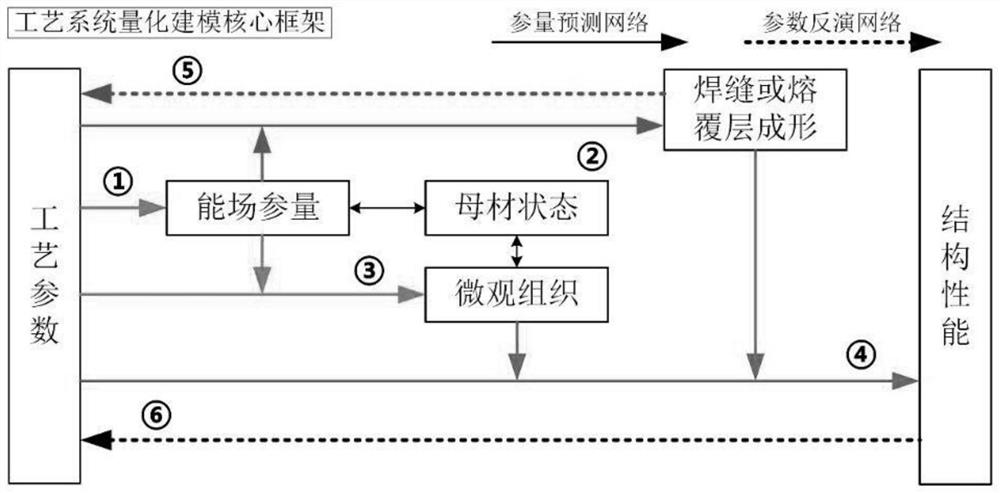

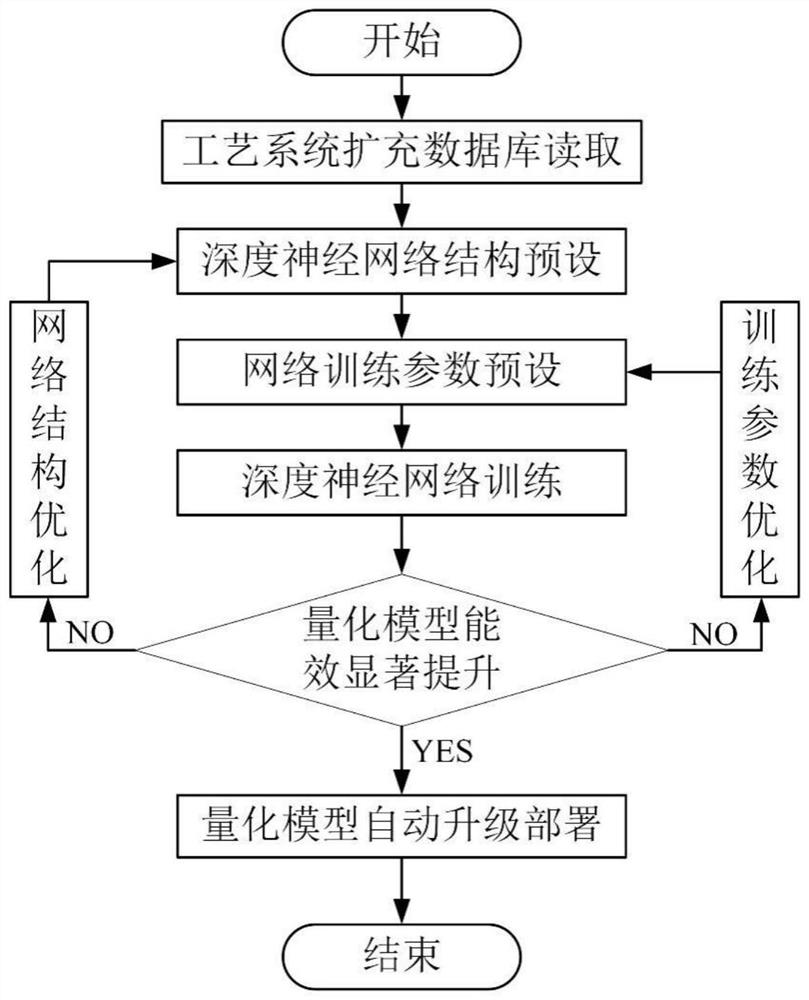

[0064] refer to figure 1 As shown, the metal additive manufacturing process system multi-dimensional data fusion and quantitative modeling method provided in this embodiment mainly includes the following steps:

[0065] 101. Obtain diverse, multivariate, multi-dimensional, discrete, strongly coupled original data that is highly correlated with the metal additive manufacturing process system, and preprocess the data to obtain the metal additive manufacturing process data;

[0066] Perform distribution status assessment, classification screening, feature extraction, and normalization processing on the metal additive manufacturing process data to obtain the normalized structural data of the metal additive manufacturing process system;

[0067] In this step, through structured and normalized processing of metal additive manufacturing process data, the huge differences in data sources, types, content, dimensions, scope, etc. are weakened or eliminated, and the focus on data and dat...

Embodiment 2

[0125] The method provided in Example 1 is used to build a 5083 aluminum alloy twin-wire CMT cladding forming prediction system, focusing on the complete process and effect of the quantitative modeling of the metal additive manufacturing process system. Among them, the additive equipment model is FroniusTransPlus Synergic 5000CMT R, The model of the automatic arc welding robot is KUKA KR 60HA, the substrate grade is 5083-H116 aluminum alloy, the substrate size is 300mm×150mm×8mm, a total of 6 pieces; the arc type is double-wire eutectic pool, the front wire pulse PULS+ rear wire CMT method, The filler metal is ESAB OK Autrod 5183 aluminum alloy wire with a diameter of 1.2mm and an arc voltage of 24V; when the currents of the front wires are 160A, 200A, and 240A, the currents of the rear wires are 60A, 80A, 100A, 120A, 140A, and 160A. ;When the CMT current of the rear wire is 160A, 200A, 240A respectively, the pulse current of the front wire is 60A, 110A, 160A, 210A, 260A, 310A ...

Embodiment 3

[0141] The method provided in Example 1 is used to build a quantitative model of the robot arc additive manufacturing process system, focusing on the data fusion and quantitative modeling ideas for the quantitative modeling of complex process systems. Among them, the additive equipment model is FroniusTransPlus Synergic 5000CMT R, automatic The arc welding robot model is KUKA KR 20R1810, the wire grade is Jingtai MIG304, OK Autrod 308LSi, the diameter of the welding wire is 1.0mm, 1.2mm, the shielding gas is pure argon, Ar+5%CO binary mixed gas, and the gas flow rate is 12L / min, 15L / min, substrate material grades are 304 stainless steel, 316 stainless steel, substrate size is 300mm×150mm×8mm, 300mm×150mm×10mm, additive speed gradient is 1-2-3-4-5-6- 7-8-9-10mm / s, the wire feeding speed gradient is 3-4-5-6m / min, the ambient temperature is 25°C, 30°C, the additive path is zigzag, spiral, and the additive structure is a solid square. It is convenient for forming and performance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com