Micron-sized homogeneous biomagnetic microsphere and preparation method thereof

A magnetic microsphere and micron-scale technology, which is applied in the combined field of nanomaterials and biotechnology engineering, can solve the problems of high difficulty in process control, long preparation process, and complicated particle size control, and achieve good industrial reproducibility and responsiveness. Highly controllable conditions and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

[0028] Add 5g of styrene, 0.28g of azobisisobutyronitrile, 0.84g of polyvinylpyrrolidone K-300.84g, and 100g of ethanol into a 250mL three-necked flask. The three ports are respectively connected to the nitrogen inflow pipe, polytetrafluoroethylene stirring paddle, and spherical condenser. device, so that the device was fed with nitrogen protection and stirred for 30 min at a stirring rate of 300 rpm. Then under the protection of nitrogen, the temperature was raised to 75 degrees to initiate polymerization. After the polymerization was carried out for 1 hour, 5 g of styrene and 0.5 g of divinylbenzene were slowly introduced every 2 hours, and a total of 4 repetitions were carried out, so that the total amount of styrene in the reaction liquid reached 25 g. The total amount of divinylbenzene reaches 2 g. After the introduction of monomers, the reaction was continued until the entire polymerization process reached 24h, and the polymerization was always protected by nitrogen. Af...

specific example 2

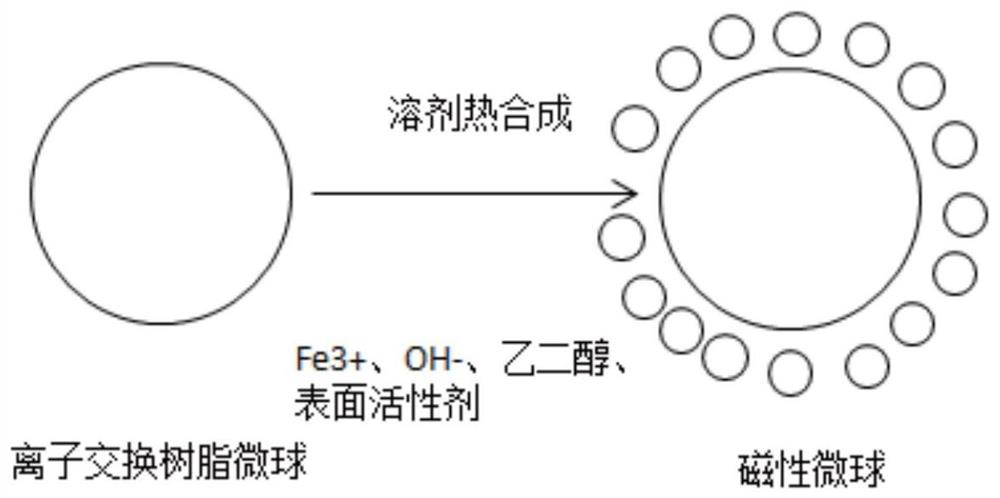

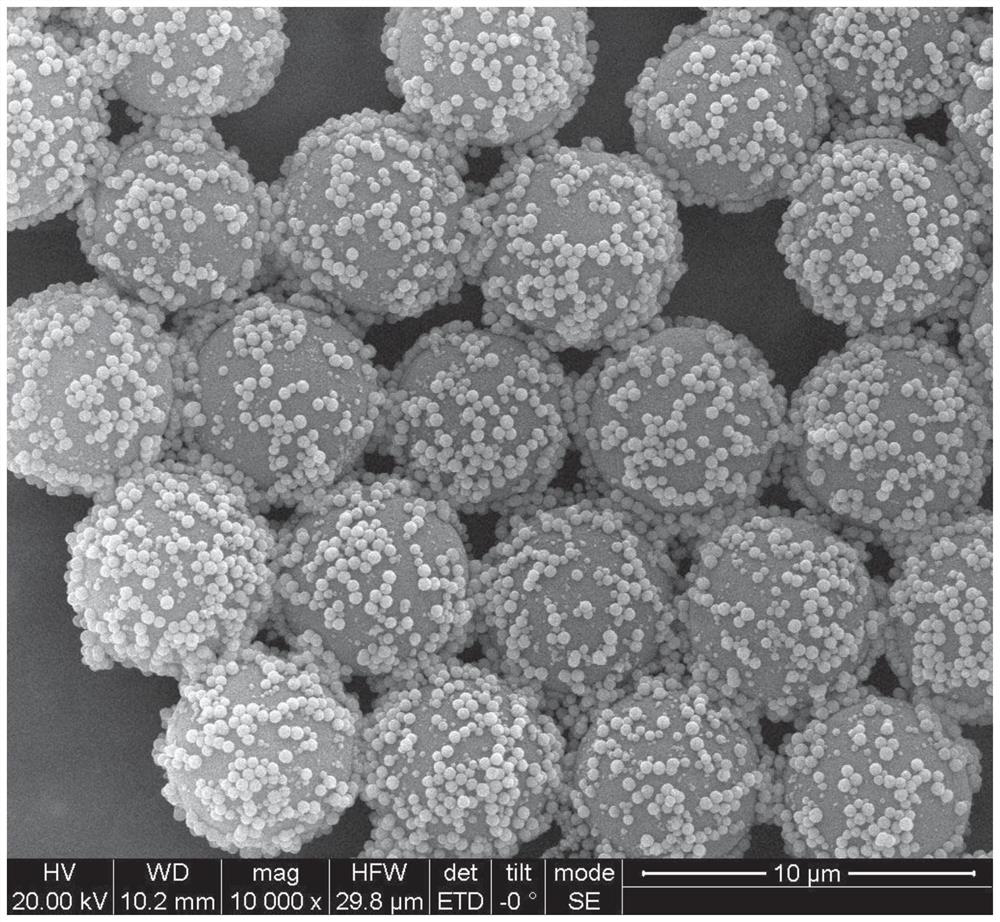

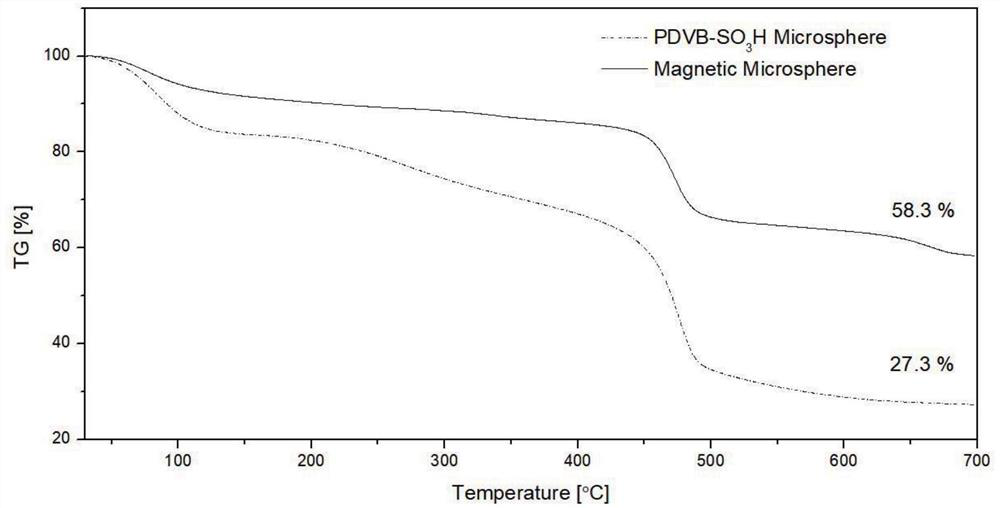

[0032] Take 1 g of sulfonated ion-exchange resin microspheres with a surface of 5 μm in specific example 1, disperse them in 150 mL of ethylene glycol, add 5 g of ferric chloride hexahydrate, 13 g of anhydrous sodium acetate, and 5 g of polyacrylic acid (molecular weight ~ 20000) Stir vigorously at 60°C for 24h. The reaction suspension was transferred to a 200mL autoclave, and the temperature was raised to 200°C for 12 hours. After the product was cooled, it was magnetically separated, washed several times with pure water, and the total amount of homogeneous magnetic microspheres was ~0.8g.

specific example 3

[0034] Take 1g of 5 μm average particle surface carboxylated ion exchange resin microspheres in Example 1, disperse them in 120mL of triethylene glycol, add 4.5g of ferric chloride, 21g of sodium citrate, and 5g of sodium polyacrylate (molecular weight ~ 200000) Stir vigorously at 60°C for 24h. The reaction suspension was transferred to a 200mL autoclave, and the temperature was raised to 190°C for 24h. After the product was cooled, it was magnetically separated, washed several times with pure water, and the total amount of homogeneous magnetic microspheres was ~0.8g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com