Titanium diboride coated silicon carbon material, preparation method and application thereof

A technology of titanium diboride and silicon carbon materials, applied in electrical components, battery electrodes, non-aqueous electrolyte storage batteries, etc., can solve the problems of poor cycle performance of silicon carbon materials, and achieve increased rate performance, improved conductivity, and acid resistance strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

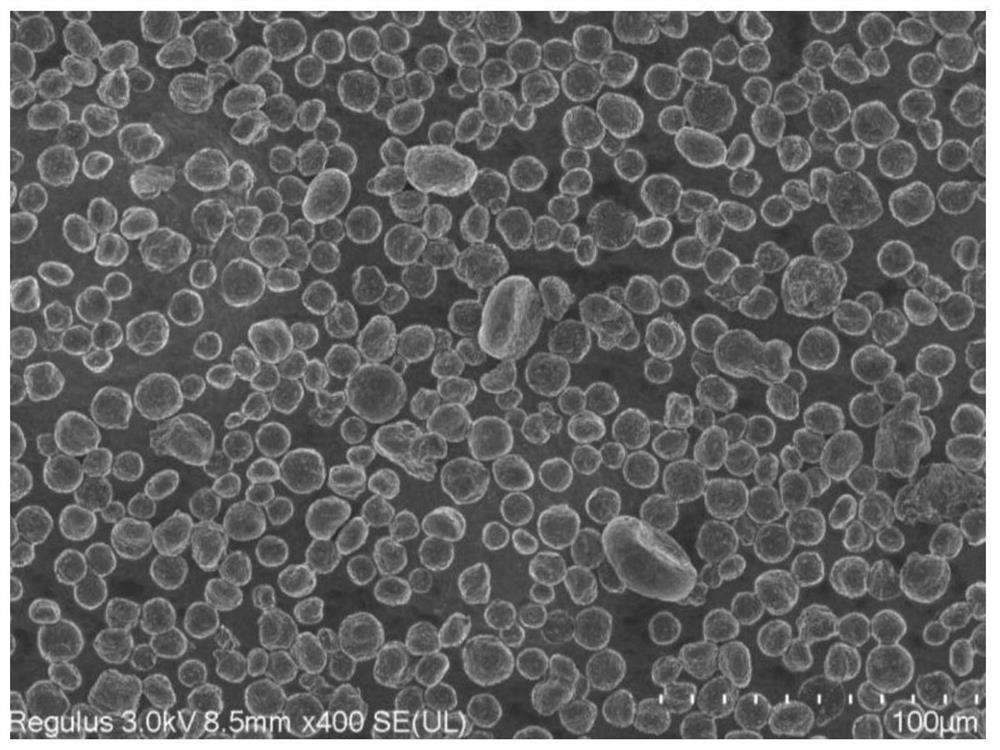

[0027] The aforementioned titanium diboride-coated silicon-carbon material of the present application may be coated by a conventional coating method, for example, the silicon-carbon material is prepared first, and then reacted in situ on it to form a titanium dioxide coating layer. In order to improve the bonding strength between layers, in another typical embodiment of the present application, a method for preparing a titanium diboride-coated silicon carbon material is provided, the preparation method comprising: step S1, Prepare silicon-carbon composite material precursor; step S2, prepare titanium diboride precursor solution; step S3, mix silicon-carbon composite material precursor and titanium diboride precursor solution, spray dry, and obtain titanium diboride coating The silicon carbon material precursor; step S4, sintering the silicon carbon material precursor covered with titanium diboride, to obtain the silicon carbon material covered with titanium diboride.

[0028] ...

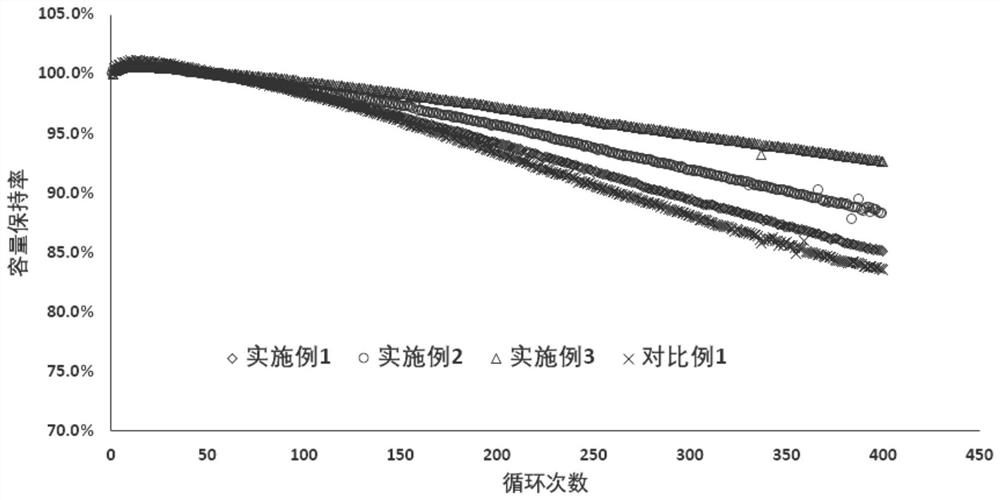

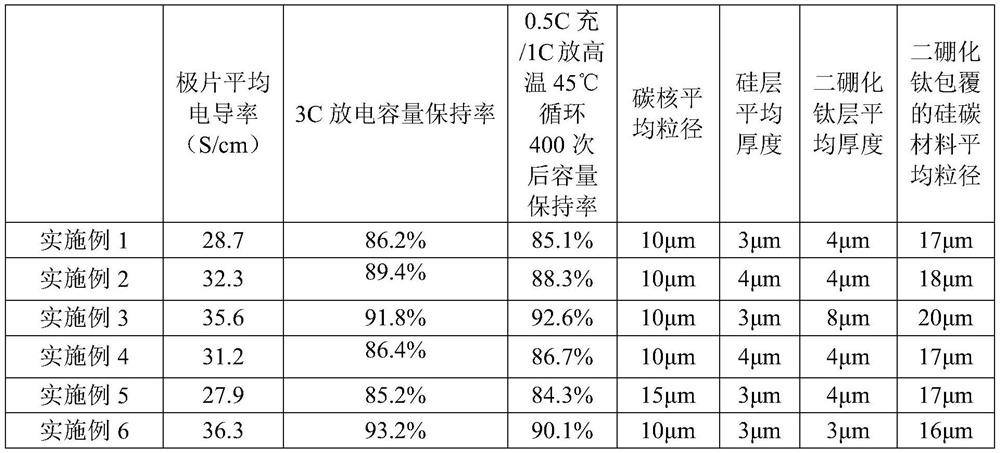

Embodiment 1

[0040] (1) Add nano-silica powder with an average particle size of 50nm, mesocarbon microspheres with an average particle size of 10μm, and polyvinyl alcohol into deionized water at a mass ratio of 1:6:1 for mixing and dispersion to obtain silicon carbon Slurry, the solid content of the slurry is 20%, then the slurry is spray-dried, and after sieving, the mesophase carbon microsphere precursor coated with nano-silicon is obtained, and its thickness is recorded in Table 1;

[0041] (2) Add citric acid, ethylene glycol, and water-based polyurethane to deionized water according to the mass ratio of 1:1:1, and stir until completely dissolved to obtain a mixed solution;

[0042] (3) adding diboron trioxide and titanium tetrachloride to the mixed solution according to a mass ratio of 1:1, and stirring at 55° C. until completely dissolved to obtain a titanium diboride precursor solution;

[0043] (4) In the titanium diboride precursor solution in step (3), the mass ratio of the mesop...

Embodiment 2

[0046] (1) Add nano-silica powder with an average particle size of 50nm, mesocarbon microspheres with an average particle size of 10μm, and polyvinyl alcohol into deionized water at a mass ratio of 1:6:1 for mixing and dispersion to obtain silicon carbon Slurry, the solid content of the slurry is 22%, and then the slurry is spray-dried and sieved to obtain a nano-silicon-coated mesophase carbon microsphere precursor. The average thickness of the silicon layer is recorded in Table 1;

[0047] (2) Add citric acid, ethylene glycol, and water-based polyurethane to deionized water according to the mass ratio of 1:1:1, and stir until completely dissolved to obtain a mixed solution;

[0048] (3) adding diboron trioxide and titanium tetrachloride to the mixed solution according to a mass ratio of 1:1, and stirring at 55° C. until completely dissolved to obtain a titanium diboride precursor solution;

[0049] (4) In the titanium diboride precursor solution in step (3), the mass ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap