A method for surface metallization of ceramic filter

A ceramic filter and surface metal technology, which is applied to waveguide devices, circuits, electrical components, etc., can solve problems such as crystal transformation and affecting the performance of ceramic substrates, and achieve improved adhesion, high production efficiency, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

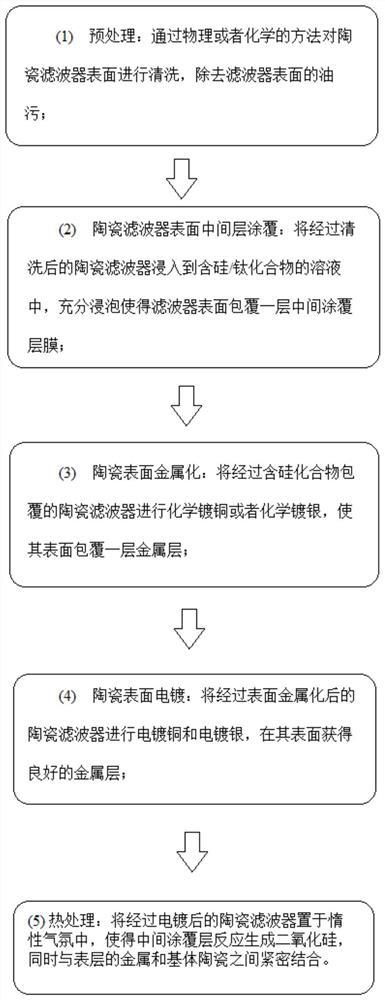

[0030] A method for metallizing the surface of a ceramic filter, such as figure 1 shown, including the following steps:

[0031] (1) Pretreatment: Clean the surface of the ceramic filter by physical methods to remove the oil on the surface of the filter to ensure the adhesion of the metal layer on the ceramic surface. As for the physical cleaning method, one or more combinations of ultrasonic cleaning, plasma cleaning, high-pressure water jet cleaning or electric pulse cleaning can be selected.

[0032] (2) Coating of the intermediate layer on the surface of the ceramic filter: immerse the cleaned ceramic filter in a solution containing a silicon compound, and fully soak it so that the surface of the filter is coated with an intermediate coating film; the solution containing a silicon compound It is an aqueous solution of silane coupling agent, and the mass concentration of silane coupling agent in the solution is 5-10%. The silane coupling agent can also be replaced by silic...

Embodiment 2

[0037] On the basis of Example 1, process parameters can be modified

[0038] A method for metallizing the surface of a ceramic filter, such as figure 1 shown, including the following steps:

[0039] (1) Pretreatment: Clean the surface of the ceramic filter by chemical methods to remove the oil on the surface of the filter to ensure the adhesion of the metal layer on the ceramic surface. The chemical cleaning adopts pickling.

[0040] (2) Coating of the intermediate layer on the surface of the ceramic filter: immerse the cleaned ceramic filter in a solution containing a titanium compound, and fully soak it so that the surface of the filter is coated with an intermediate coating film; the solution containing a titanium compound It is an ethanol solution of titanate, and the mass concentration of titanate is 10-30%. The titanate can also be replaced by titanate, titanate and titanium-containing coupling agent, which should ensure that the compound is uniformly dispersed. This...

Embodiment 3

[0045] On the basis of Example 1, process parameters can be modified

[0046]A method for metallizing the surface of a ceramic filter, such as figure 1 shown, including the following steps:

[0047] (1) Pretreatment: Clean the surface of the ceramic filter by chemical methods to remove the oil on the surface of the filter to ensure the adhesion of the metal layer on the ceramic surface. The chemical cleaning adopts alkaline cleaning.

[0048] (2) Intermediate layer coating on the surface of the ceramic filter: immerse the cleaned ceramic filter into a solution containing silicon / titanium compounds, and fully soak so that the surface of the filter is coated with a layer of intermediate coating film;

[0049] The silicon / titanium-containing compound is a mixed solution of silicate and titanium-containing coupling agent, and a dispersion of methanol solution, wherein the mass concentration of silicate is 5-10%, and the mass concentration of titanium-containing coupling agent is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com