Antibacterial polymer fiber for extracting uranium from water body and preparation method thereof

A polymer, polyacrylonitrile fiber technology, applied in the direction of fiber type, fiber treatment, alkali metal compounds, etc. Bacterial corrosion and destruction, etc., to achieve the effect of strong anti-interference ability, high antibacterial activity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

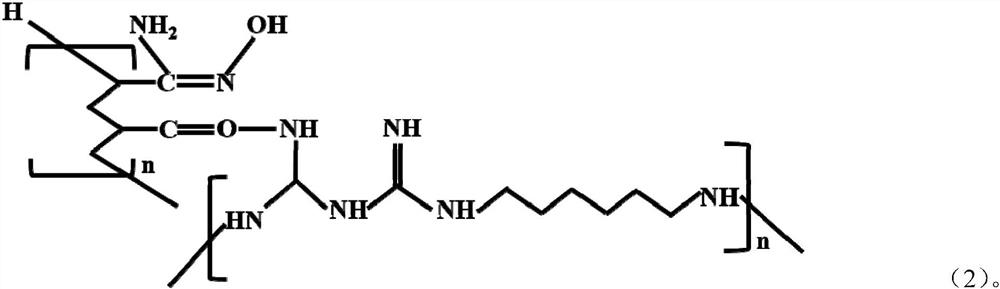

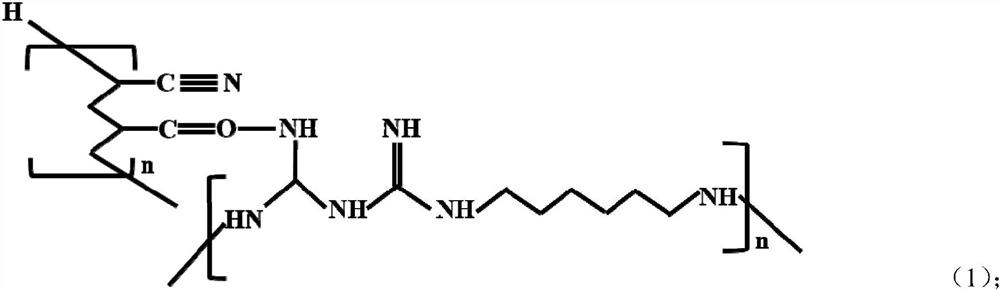

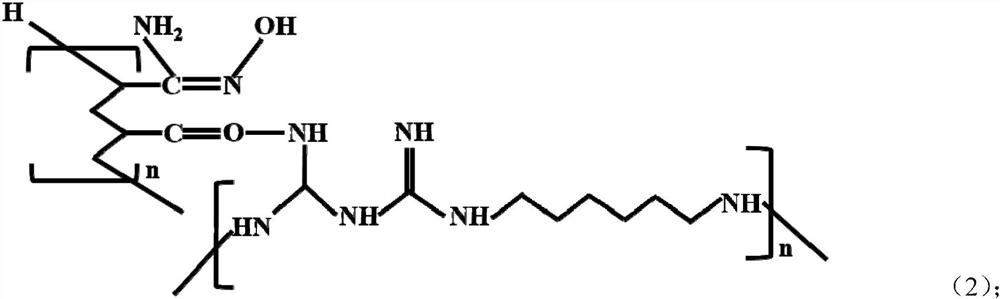

[0028] 1. Weigh 0.2g of polyhexamethylene biguanide hydrochloride and dissolve it in 20ml of deionized water, weigh 1g of polyacrylonitrile fiber and add polyhexamethylene biguanide hydrochloride solution, then put the mixed solution into the reaction kettle and react at 125°C After 24 hours, it was taken out, rinsed and dried with deionized water and ethanol to obtain the polymer fiber PAN-PHMB.

[0029] 2. Weigh 7.5g of hydroxylamine hydrochloride, prepare a mixed solution of 7.5% hydroxylamine hydrochloride in water and methanol, use sodium hydroxide to adjust the pH value to weakly alkaline, add polymer fiber PAN-PHMB, and react at 65°C for 4 hours. Then it was taken out and rinsed with deionized water and ethanol to obtain the polymer fiber PAO-PHMB.

[0030] 3. Prepare a 2.5% aqueous solution of potassium hydroxide, add the polymer fiber PAO-PHMB obtained in step 2, and react at 60°C for 4 hours, then take it out and rinse it with deionized water and ethanol to obtain th...

Embodiment 2

[0032] 1. Weigh 0.4g of polyhexamethylene biguanide hydrochloride and dissolve it in 20ml of deionized water, weigh 1g of polyacrylonitrile fiber and add polyhexamethylene biguanide hydrochloride solution, then put the mixed solution into the reaction kettle and react at 130°C After 24 hours, it was taken out, rinsed and dried with deionized water and ethanol to obtain the polymer fiber PAN-PHMB.

[0033] 2. Weigh 8.5g of hydroxylamine hydrochloride, prepare a mixed solution of 8.5% hydroxylamine hydrochloride in water and methanol, use sodium hydroxide to adjust the pH value to weakly alkaline, add polymer fiber PAN-PHMB, and react at 65°C for 4 hours. Then it was taken out and rinsed with deionized water and ethanol to obtain the polymer fiber PAO-PHMB.

[0034] 3. Configure a 3.5% aqueous solution of potassium hydroxide, add the polymer fiber PAO-PHMB obtained in step 2, and react at 70°C for 4 hours, then take it out and rinse and dry with deionized water and ethanol to ob...

Embodiment 3

[0036] 1. Weigh 0.6g of polyhexamethylene biguanide hydrochloride and dissolve it in 20ml of deionized water, weigh 1g of polyacrylonitrile fiber and add polyhexamethylene biguanide hydrochloride solution, then put the mixed solution into the reaction kettle and react at 100°C After 24 hours, it was taken out, rinsed and dried with deionized water and ethanol to obtain the polymer fiber PAN-PHMB.

[0037] 2. Weigh 9.5g of hydroxylamine hydrochloride, prepare a mixed solution of 9.5% hydroxylamine hydrochloride in water and methanol, use sodium hydroxide to adjust the pH value to weakly alkaline, add polymer fiber PAN-PHMB, and react at 65°C for 4 hours. Then it was taken out and rinsed with deionized water and ethanol to obtain the polymer fiber PAO-PHMB.

[0038] 3. Configure a 4.5% potassium hydroxide aqueous solution, add the polymer fiber PAO-PHMB obtained in step 2, and react at 80°C for 3 hours, then take it out and rinse and dry with deionized water and ethanol to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com